Flame-resistant type polyurethane emulsion and preparation method thereof

A polyurethane emulsion, flame-retardant technology, applied in the field of fine polymers, can solve the problems of affecting the service life and reducing the flame-retardant effect, and achieve good flame-retardant and excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

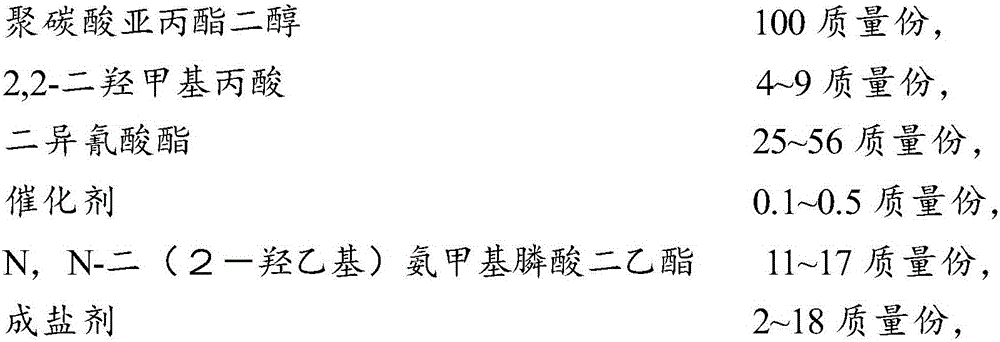

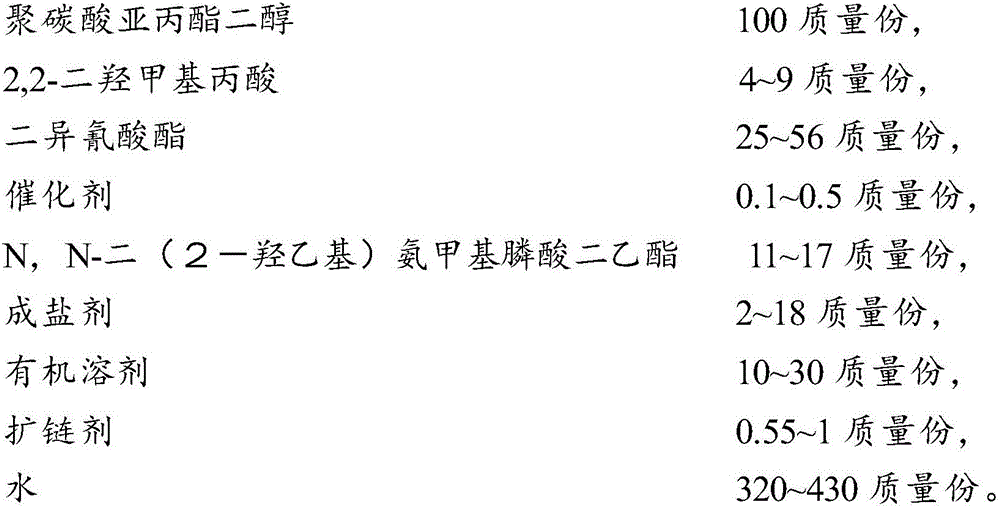

[0045] The raw materials for the preparation of the flame-retardant polyurethane emulsion provided by the present invention also include 4 to 9 parts by mass of 2,2-dimethylol propionic acid (DMPA), preferably 5 to 8 parts by mass, more preferably 6 to 7 parts by mass .

[0046] The raw materials for preparing the flame-retardant polyurethane emulsion provided by the present invention further include 25-56 parts by mass of diisocyanate, preferably 30-50 parts by mass, more preferably 35-45 parts by mass. The diisocyanate is selected from one or more of isophorone diisocyanate, hexamethylene diisocyanate, toluene diisocyanate and diphenylmethane diisocyanate; more preferably, the diisocyanate is isophorone A combination of ketone diisocyanate and hexamethylene diisocyanate.

[0047] The raw materials for preparing the flame-retardant polyurethane emulsion provided by the present invention further include 0.1-0.5 parts by mass of catalyst, preferably 0.2-0.4 parts by mass, more p...

Embodiment 1

[0072] Take a certain amount of DMC catalyst, 2.5L propylene oxide and relative molecular mass regulator DPG and add it to a dry 5L high-pressure reactor, seal the reactor, turn on the stirring device, and add 1.3kgCO 2 , heated up to 60°C while stirring, reacted for 12h and discharged to obtain polypropylene carbonate diol.

[0073] The number average molecular weight of the polypropylene carbonate diol was determined to be 3000, the hydroxyl functionality was 2, and the mole fraction of carbonate groups in the molecule was 30%.

[0074] Take 100 parts of the polypropylene carbonate diol prepared in Example 1, add it into a glass reactor with a vacuum device, vacuum dehydrate it at 120°C for 2 hours, lower it to normal temperature, and add 2,2-dimethylol propionic acid 7 parts, add 25 parts of N,N-dimethylamide, add 43 parts of hexamethylene diisocyanate and isophorone diisocyanate, 0.3 parts of stannous isooctanoate, react at 80 degrees for 3-4 hours, add flame retardant 11...

Embodiment 2

[0076] Take 100 parts of the polypropylene carbonate diol prepared in Example 1, add it into a glass reactor with a vacuum device, vacuum dehydrate it at 120°C for 2 hours, lower it to normal temperature, and add 2,2-dimethylol propionic acid 9 parts, add 25 parts of N,N-dimethylamide, add 52 parts of hexamethylene diisocyanate and isophorone diisocyanate, 0.32 parts of stannous isooctanoate, react at 80 degrees for 3-4 hours, add flame retardant 14 parts of N, N-di(2-hydroxyethyl)aminomethylphosphonic acid diethyl ester, react for 10-20 minutes. Lower the temperature by 30 degrees, add 6.8 parts of triethylamine for neutralization, add 380 parts of deionized water to emulsify to obtain component A, and finally add 10 parts of deionized water and 1 part of ethylenediamine to mix uniformly for component B. The chain is extended for 20-30 minutes to obtain a flame-retardant polyurethane emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com