Water-based polyurethane emulsion for heat-resistant transfer coating and preparation method thereof

A technology of water-based polyurethane and transfer coating, which is applied in the field of coatings, can solve the problems of poor temperature resistance and peeling property, and achieve the effects of good production quality, easy control of reaction and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

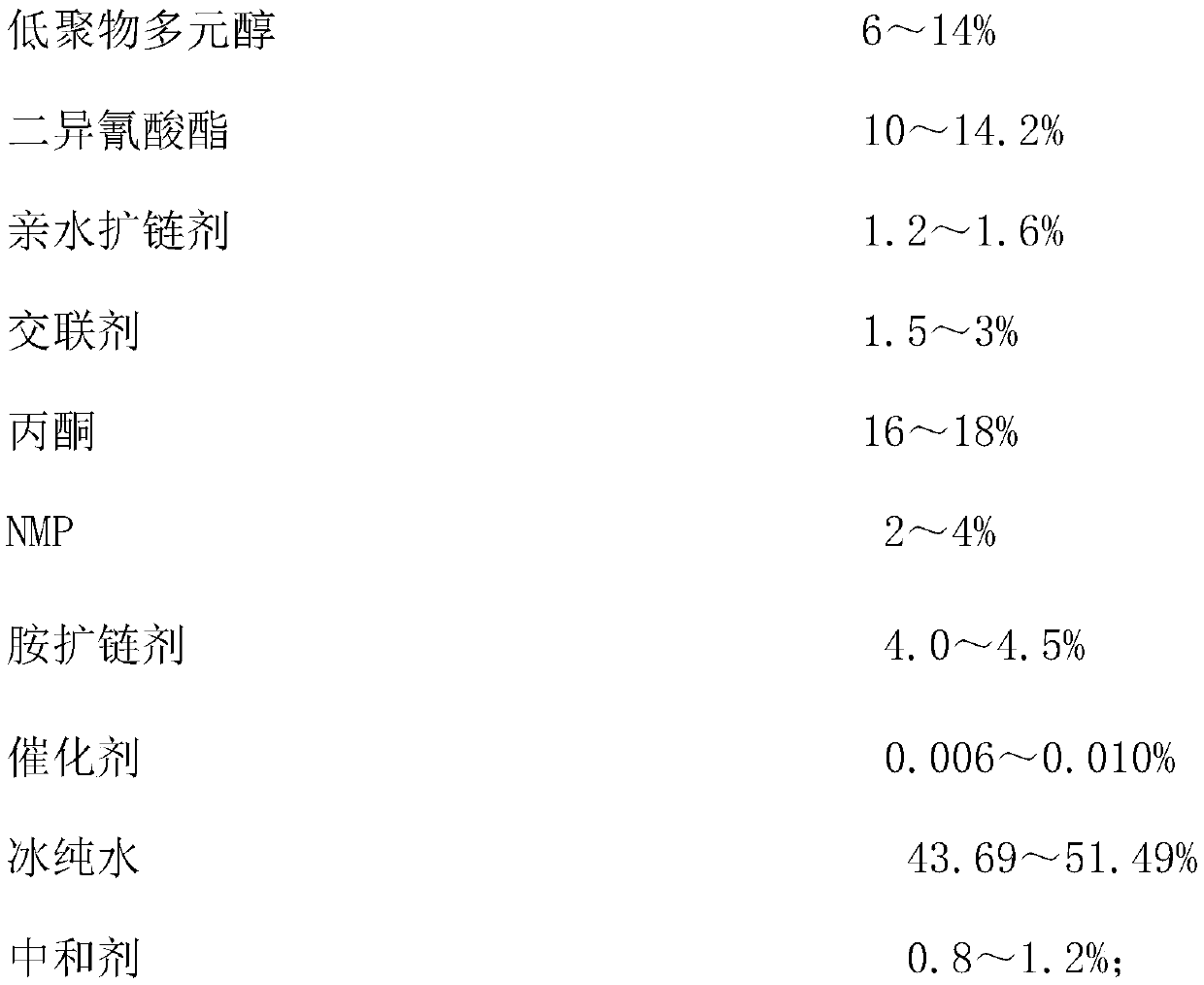

[0035] A water-based polyurethane emulsion for heat-resistant transfer coatings, comprising the following components by weight:

[0036]

[0037] The preparation method of the water-based polyurethane emulsion of the temperature-resistant transfer coating of embodiment 1 may further comprise the steps:

[0038] 1) Under the protection of dry nitrogen, dehydrate and vacuum polycarbonate diol (PCDL) at 110°C for 1 hour, and cool down to 60°C;

[0039] 2) Add H12MDI, heat up to 88°C from exotherm, react for 2 hours, then cool down to 54°C;

[0040] 3) Mix dimethylolpropionic acid (DMPA), TMP, CHDM, BEPD cross-linking agent and NMP, then add, the temperature should not rise too fast, react at 75°C for 1 hour;

[0041] 4) Add the catalyst and react at 65°C for 2 hours;

[0042] 5), while cooling down, add acetone and cool down to 35°C;

[0043] 6) Discharge the prepolymer into the dispersion bucket, quickly add DMEA, and disperse at high speed for 1 minute;

[0044] 7) Quick...

Embodiment 2

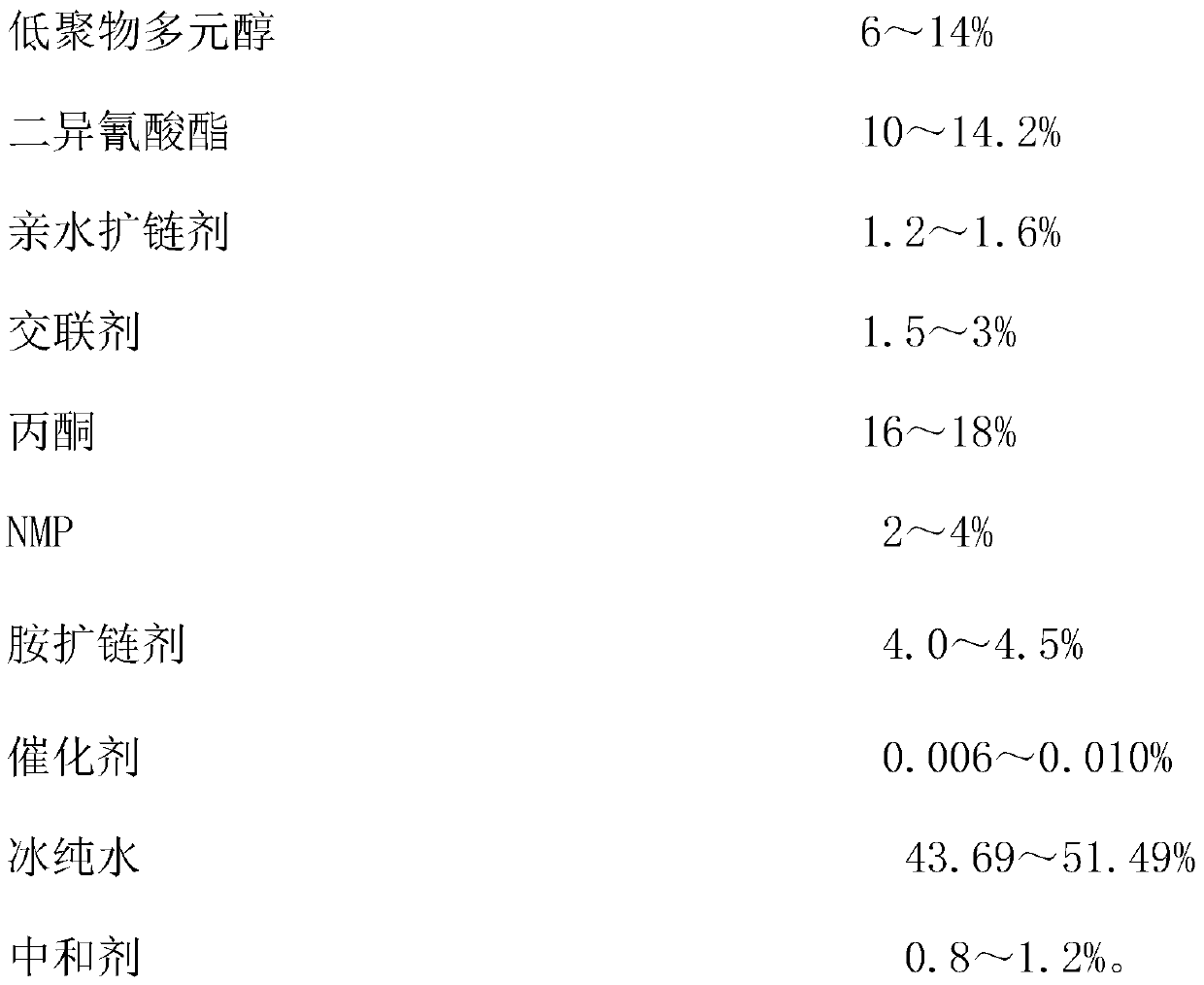

[0047] A water-based polyurethane emulsion for heat-resistant transfer coatings, comprising the following components by weight:

[0048]

[0049] The preparation method of the water-based polyurethane emulsion of the temperature-resistant transfer coating of embodiment 2 may further comprise the steps:

[0050] 1) Under the protection of dry nitrogen, dehydrate polycarbonate diol (PCDL) at 105°C for 1 hour and then cool it down to 55°C;

[0051] 2) Add H12MDI, heat up to 86°C from exotherm, react for 2 hours, then cool down to 53°C;

[0052] 3) Mix dimethylolpropionic acid (DMPA), TMP, CHDM, BEPD cross-linking agent and NMP, then add, the temperature should not rise too fast, react at 72°C for 1 hour;

[0053] 4), add the catalyst, react at 63°C for 2 hours,

[0054] 5), while cooling down, add acetone and cool down to 33°C;

[0055] 6) Discharge the prepolymer into the dispersion barrel, quickly add DMEA aqueous solution, and disperse at high speed for 1 minute;

[005...

Embodiment 3

[0059] A water-based polyurethane emulsion for heat-resistant transfer coatings, comprising the following components by weight:

[0060]

[0061]

[0062] The preparation method of the water-based polyurethane emulsion of the temperature-resistant transfer coating of embodiment 3 may further comprise the steps:

[0063] 1) Under the protection of dry nitrogen, dehydrate and vacuum neopentyl glycol adipate (PNA) at 108°C for 1 hour, and cool down to 55°C;

[0064] 2) Add H12MDI, heat up to 85°C from exotherm, react for 2 hours, then cool down to 52°C;

[0065] 3) Mix dimethylolpropionic acid (DMPA), TMP, CHDM and BEPD cross-linking agent and NMP, then add, the temperature should not rise too fast, react at 72°C for 1 hour;

[0066] 4) Add the catalyst and react at 62°C for 2 hours;

[0067] 5), while cooling down, add acetone and cool down to 32°C;

[0068] 6) Discharge the prepolymer into the dispersion bucket, quickly add DMEA aqueous solution, and disperse at high s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com