A method for preparing paraffin dispersion and paraffin microspheres by using polymer microspheres as stabilizers

A polymer and dispersion technology, applied in the field of Pickering emulsion preparation, can solve the problems of lengthy process, complex system, high dosage of stabilizer, etc., and achieve the effect of short required time, simple experimental process and clean ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

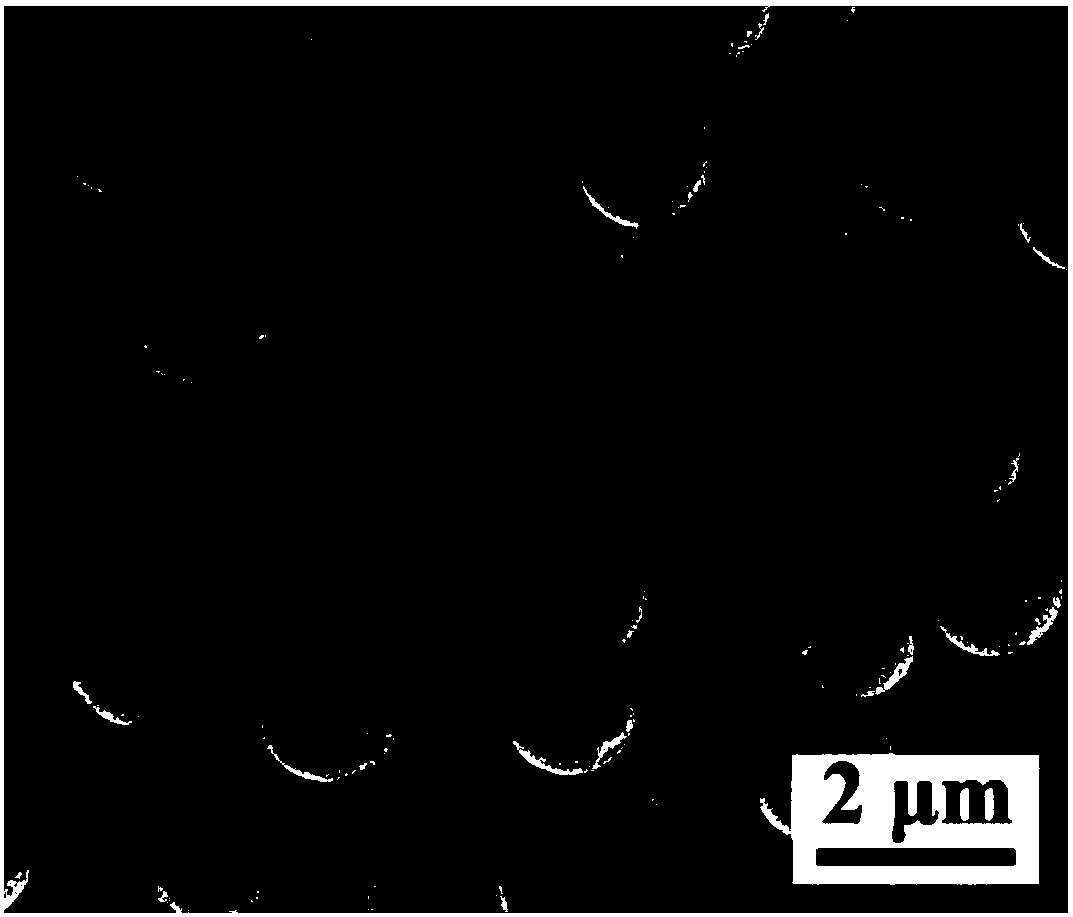

[0045] Preparation of polymer microspheres by precipitation polymerization: first add 98.0 g of water / ethanol mixed solvent with a mass ratio of 10 / 90 to a 120 mL glass reaction bottle at room temperature, and then add 1.4 g of dodecene and 0.6 g of trimethylol Propane triacrylate and 0.04 g of azobisisobutyronitrile were shaken evenly, and the reaction bottle was sealed and placed in a constant temperature water bath shaker at 70° C., and reacted at a vibration frequency of 120 osc / min for 4 hours. The product was centrifuged with a high-speed centrifuge at 8,000 rpm for 5 min, and the microspheres were washed twice with ethanol, and then dried in an oven at 100° C. for 5 h to obtain polymer microspheres. The scanning electron micrographs of the obtained polymers are shown in figure 1 , the particle size of the microspheres thus measured was 1.3 μm, and the particle size polydispersity coefficient was 1.010.

[0046] Preparation of paraffin dispersion and paraffin microspher...

Embodiment 2

[0048] Polymer microspheres were prepared according to the method described in Example 1.

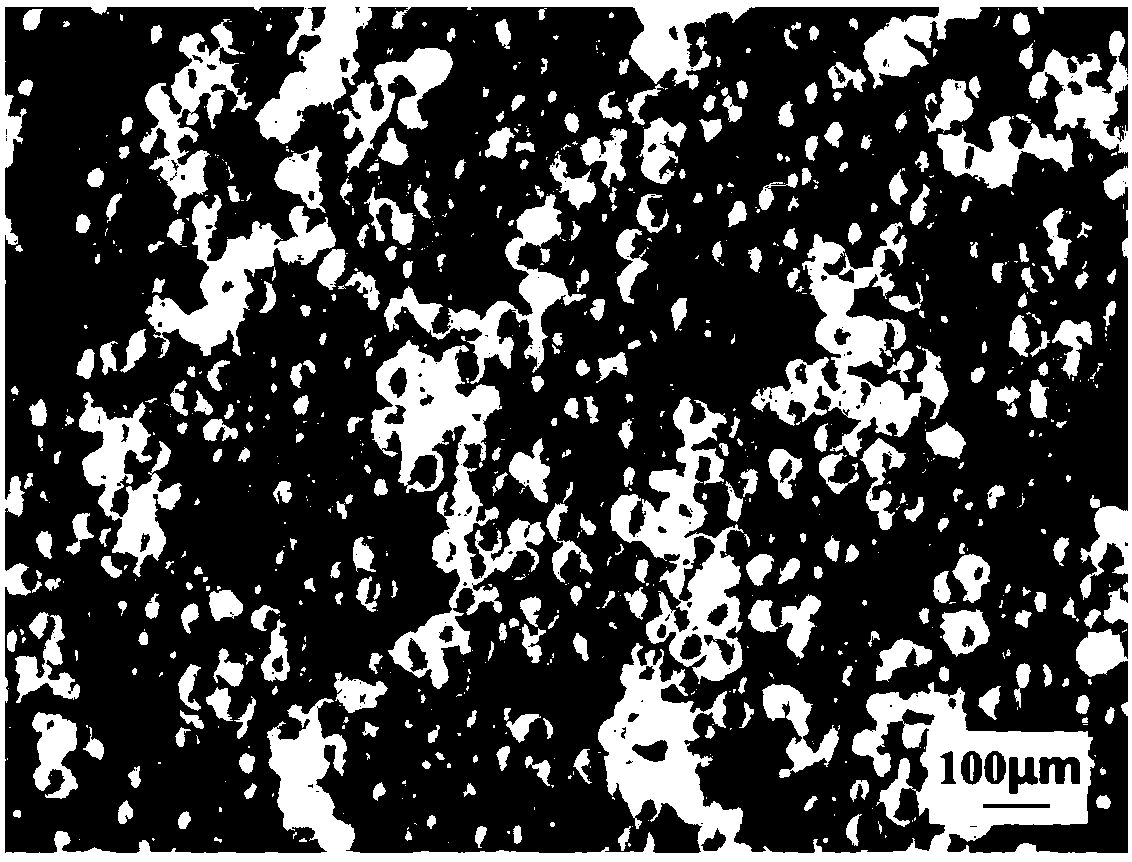

[0049] Preparation of paraffin wax dispersion and paraffin wax microspheres: Add 0.2 g of polymer microspheres, 10 g of solid paraffin with a melting point of 45 °C and 40 g of water / ethanol mixed solvent with a mass ratio of 20 / 80 into a 100 mL glass bottle at room temperature, After sealing the glass bottle, place it in a constant temperature water bath shaker at 50°C, and vibrate at a vibration frequency of 240osc / min for 30min to obtain a paraffin wax dispersion. Keep the vibration frequency constant, add room temperature water to the constant temperature water bath oscillator to solidify the paraffin droplet. Then the system was left to stand at room temperature for 2 hours, the upper liquid was removed after the system was separated, and the lower solid was dried at 40° C. to obtain paraffin microspheres. The optical microscope photograph of gained paraffin microsphere sees ima...

Embodiment 3

[0051] Polymer microspheres were prepared according to the method described in Example 1.

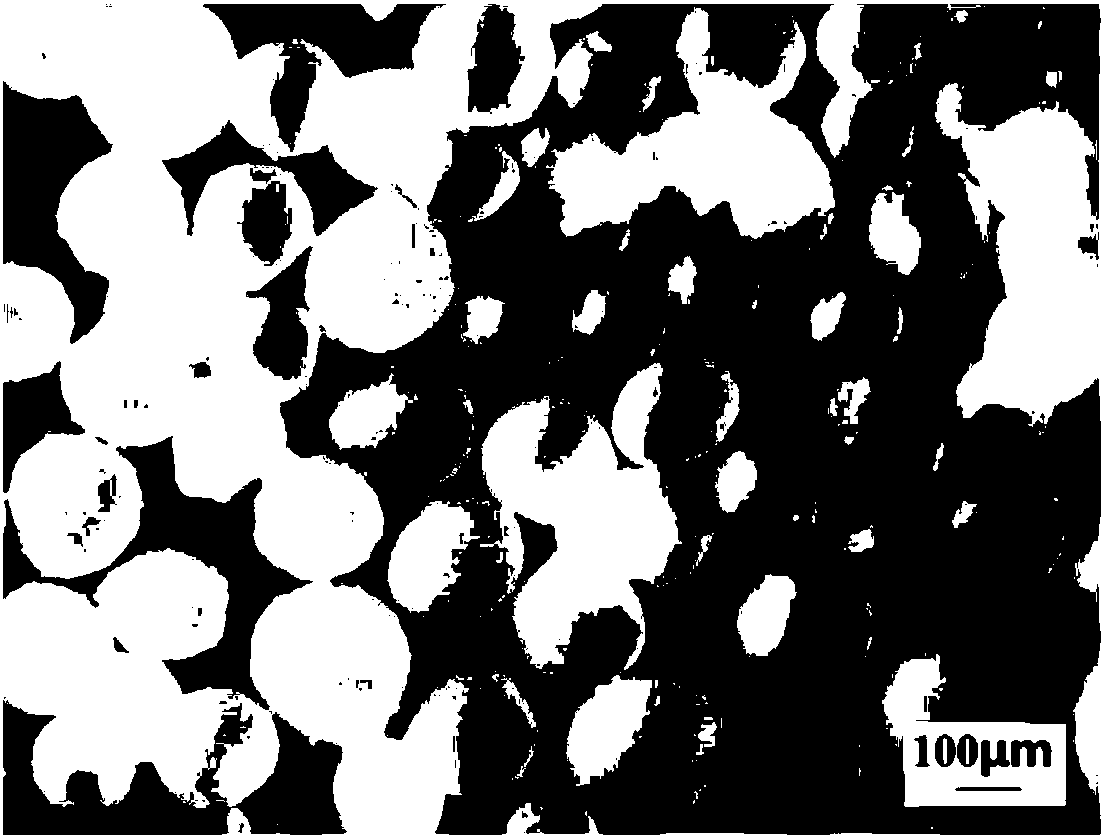

[0052] Preparation of paraffin wax dispersion and paraffin wax microspheres: Add 0.5 g of polymer microspheres, 12.5 g of solid paraffin with a melting point of 55 °C and 37.5 g of water / ethanol with a mass ratio of 30 / 70 into a 100 mL glass bottle at room temperature For the solvent, seal the glass bottle and place it in a constant temperature water bath shaker at 60°C, shake it at a vibration frequency of 200osc / min for 60min to obtain a paraffin wax dispersion. Keep the vibration frequency constant, add room temperature water to the constant temperature water bath oscillator to solidify the paraffin droplet. Then the system was left to stand at room temperature for 2 hours. After the system was separated, the upper layer liquid was removed, and the lower layer solid was dried at 50° C. to obtain paraffin microspheres. The particle size of the obtained paraffin microspheres was 287 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com