Preparation method of solvent-free type polyurethane waterproof paint with saline-alkaline resistance and root thorn resistance

A solvent-free polyurethane, root puncture-resistant technology, used in polyurea/polyurethane coatings, coatings, etc., can solve problems such as affecting the normal growth of plants, failure of composite salt-alkali-resistant additives, and unreasonable proportions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

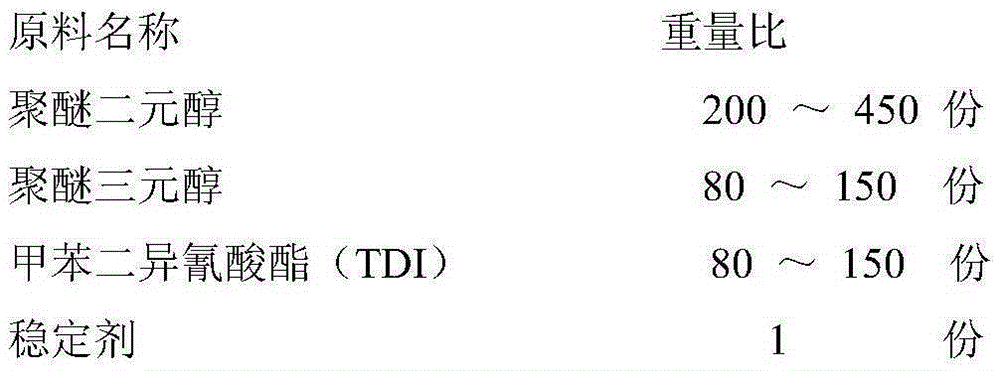

[0031] The A component is composed of the following components according to the weight ratio:

[0032]

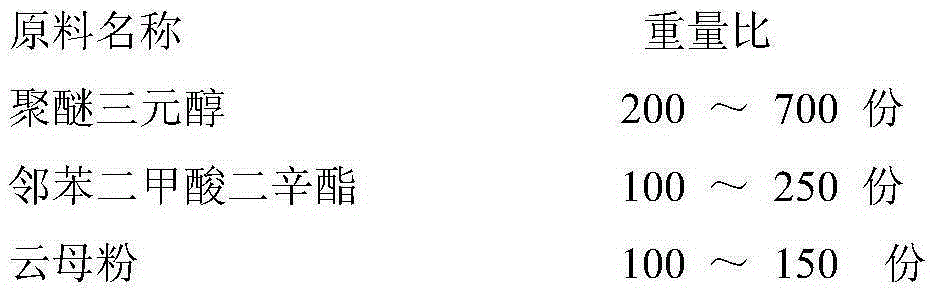

[0033] The B component is composed of the following components according to the weight ratio:

[0034]

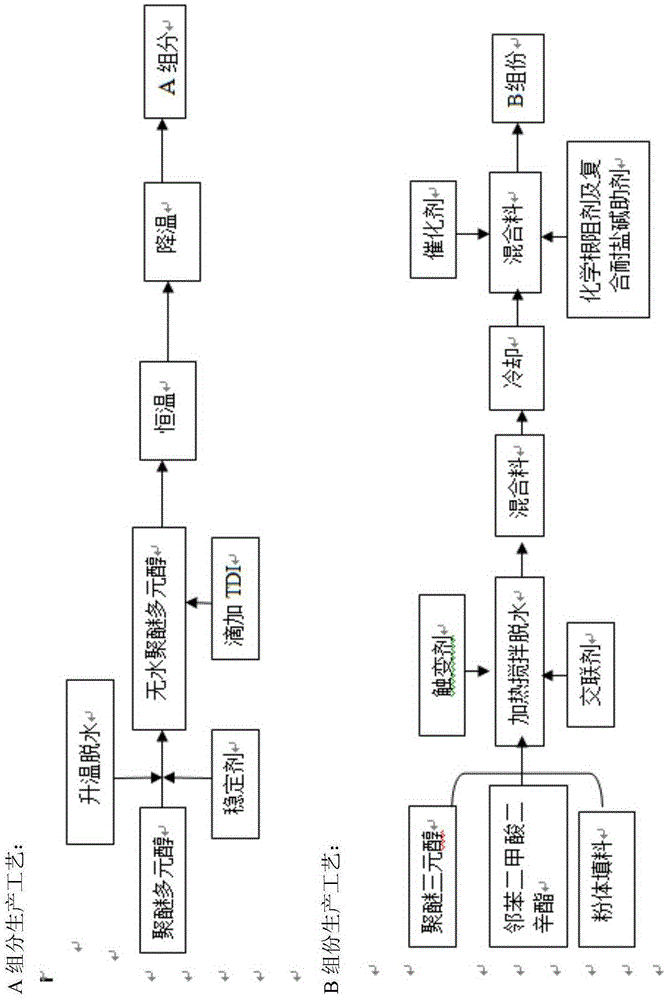

[0035] crafting process:

[0036] Preparation of component A:

[0037] (1) 300 parts of polyether glycol, 80 parts of polyether triol, and 1 part of stabilizer are added to the reactor.

[0038] (2) Raise the temperature to 80°C-100°C and start stirring.

[0039] (3) Vacuum dehydration and degassing for 1h~2h.

[0040] (4) When the temperature drops below 60°C, toluene diisocyanate (TDI) is added.

[0041] (5) The raw materials are reacted at 70°C to 90°C for 2h to 3h, vacuum degassed, and cooled to room temperature to obtain component A.

[0042] Preparation of component B:

[0043] (1) Add 500 parts of polyether triol and 250 parts of dioctyl phthalate into the reactor and slowly raise the temperature to 80°C.

[0044] (2) Slowly add 110 parts of mica powder, 100 parts of heavy calciu...

Embodiment 2

[0049] The A component is composed of the following components according to the weight ratio:

[0050]

[0051] The B component is composed of the following components according to the weight ratio:

[0052]

[0053] crafting process:

[0054] (1) Add 250 parts of polyether glycol, 100 parts of polyether triol, and 3 parts of stabilizer into the reactor.

[0055] (2) Raise the temperature to 80°C-100°C and start stirring.

[0056] (3) Vacuum dehydration and degassing for 1h~2h.

[0057] (4) When the temperature drops below 60°C, toluene diisocyanate (TDI) is added.

[0058] (5) The raw materials are reacted at 70°C to 90°C for 2h to 3h, vacuum degassed, and cooled to room temperature to obtain component A.

[0059] Preparation of component B:

[0060] (1) Add 550 parts of polyether triol and 200 parts of dioctyl phthalate into the reactor and slowly raise the temperature to 80°C,

[0061] (2) Slowly add 100 parts of mica powder, 110 parts of heavy calcium carbonate, 6 parts of iron oxide red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com