A kind of tea polyphenol cellulose fiber spunlace non-woven fabric and production method thereof

A technology of spunlace non-woven fabrics and cellulose fibers, which is applied in plant fibers, fiber treatment, biochemical fiber treatment, etc. It can solve the problems of low antibacterial stability and easy drop of tea polyphenols and inorganic salt composite antibacterial agents. , to achieve the effect of easy large-scale production, high antibacterial performance and shortened energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

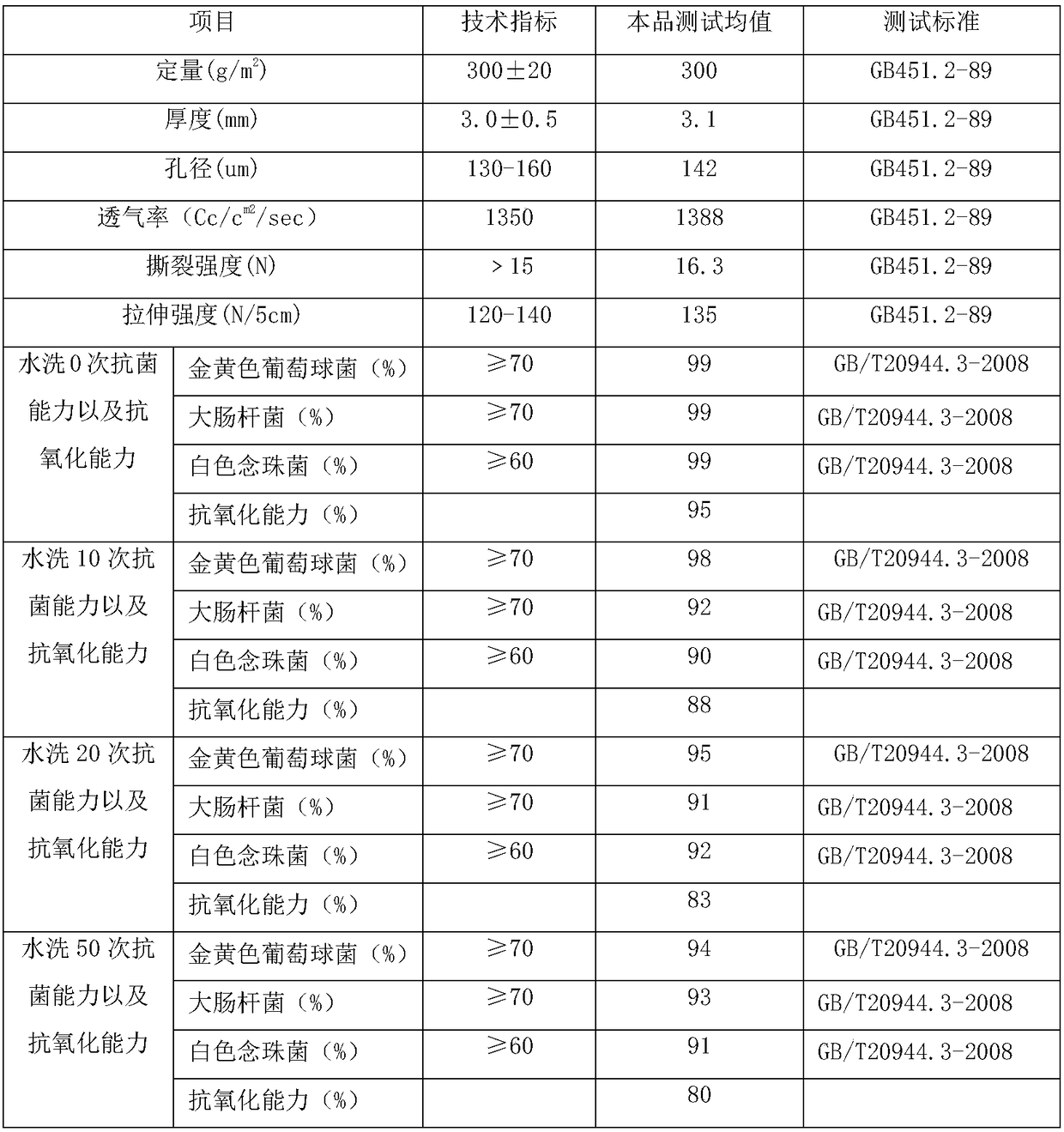

Image

Examples

Embodiment 1

[0021] A production method of tea polyphenol cellulose fiber spunlace non-woven fabric, comprising the steps of:

[0022] (1) Preparation of tea polyphenol cellulose fibers Pump 50L of water into the glass-lined reactor, start stirring, and add 10Kg of tea polyphenols, after fully dissolving, adjust the pH value of the tea polyphenols aqueous solution to 4-5 with dilute hydrochloric acid , then heat the tea polyphenol aqueous solution to 70-80°C, maintain the system temperature at 70-80°C, and add 3.5L of γ-(2,3-epoxypropoxy)propyl trimethyl dropwise to the system within 20-30min under the condition of stirring Oxysilane, after the dropwise addition, raise the system temperature to 100-110°C, maintain the system temperature at 100-110°C for 9 hours, then use dilute sodium hydroxide solution to adjust the pH value of the reaction solution to 7-8 to obtain tea polyphenols Pretreatment solution, then after cooling down to room temperature, use the injection system to add the prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com