Method for preparing polycrystalline ultra-thin metal film and two-dimensional nano pattern

An ultra-thin metal, two-dimensional nanotechnology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc. Long cycle and other problems, to achieve the effect of easy large-scale manufacturing, low cost, and large transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

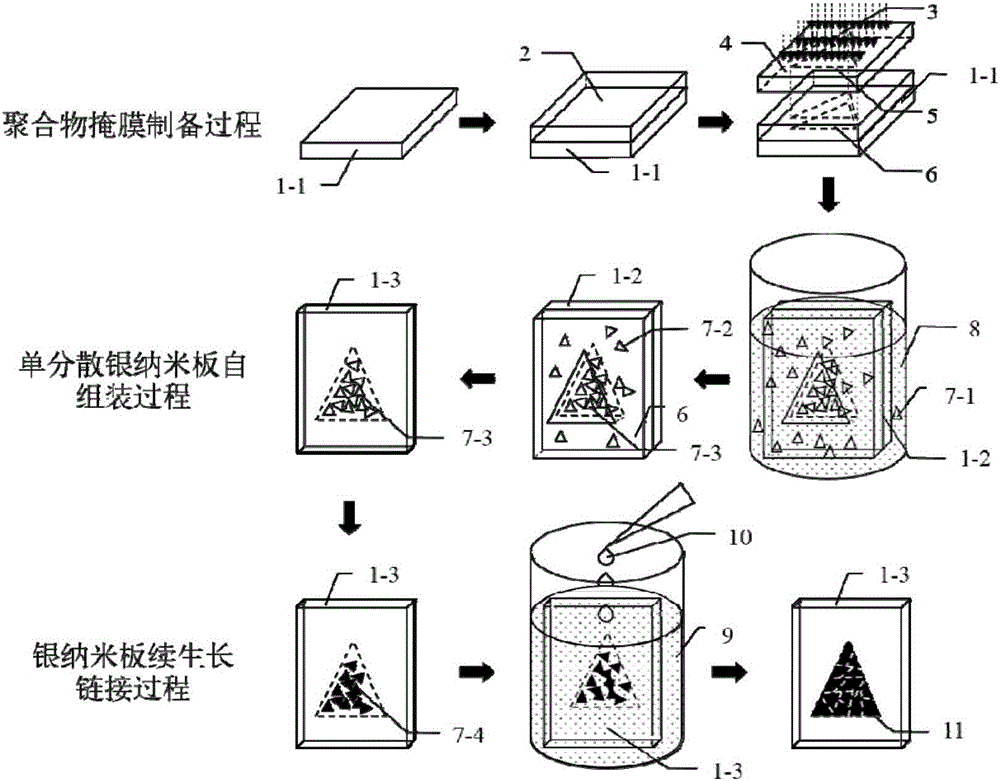

[0036] Step 1: Polymer mask preparation process

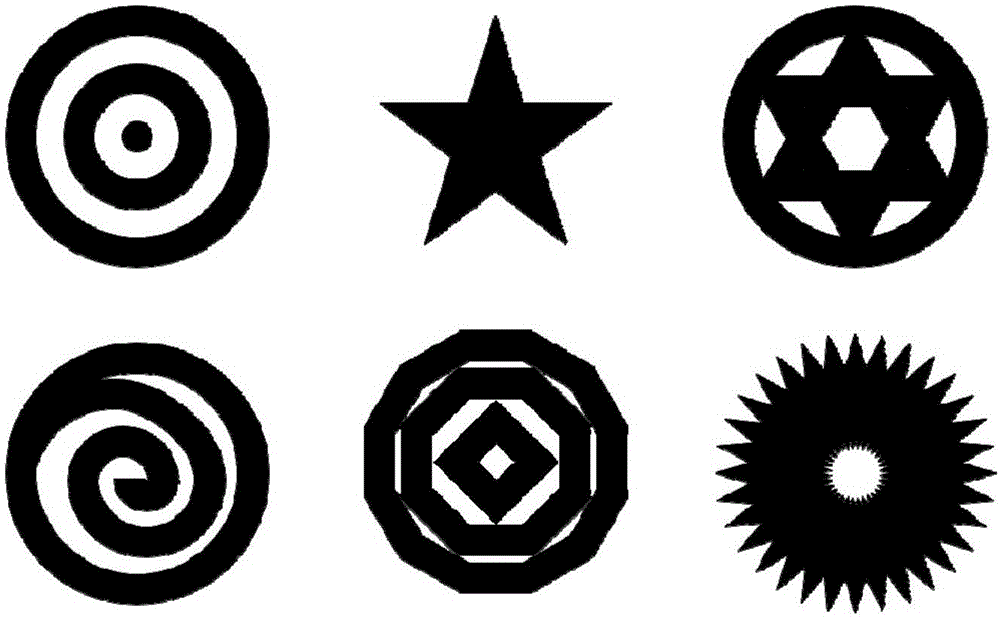

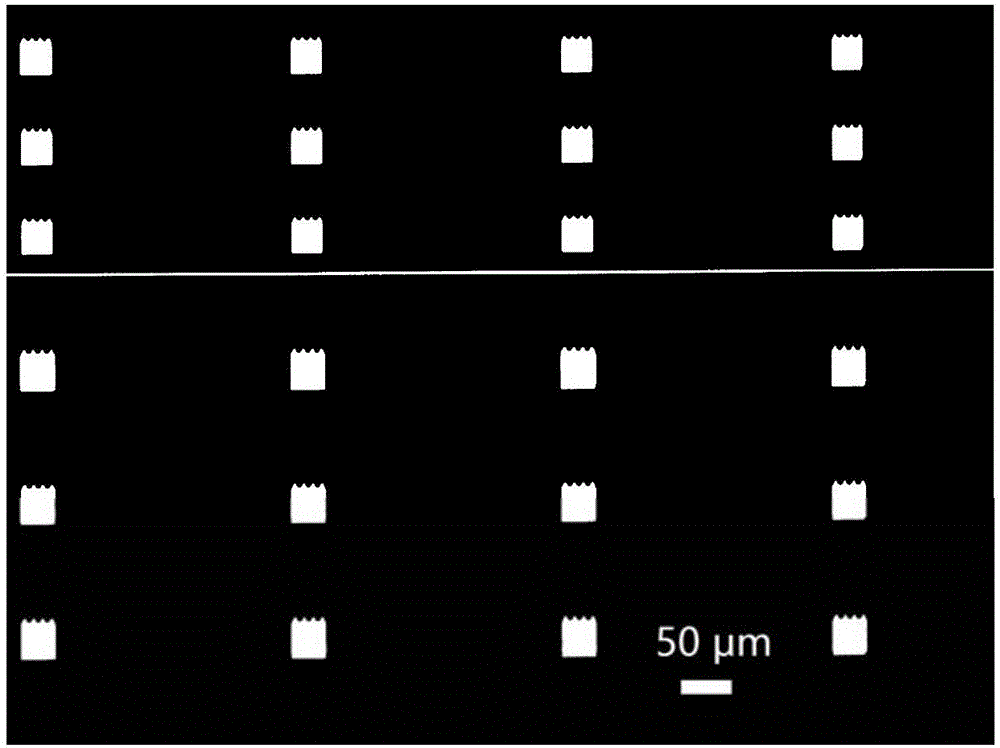

[0037] Spin-coat the UV-sensitive polymer on the silicon wafer, and transfer the two-dimensional pattern array on the mask plate to the UV-sensitive polymer after ultraviolet exposure and development, so as to obtain a polymer mask corresponding to the two-dimensional pattern array;

[0038] Step 2: Self-assembly process of monodisperse silver nanoplates

[0039] A high-yield silver nanoplate solution was obtained by using the seed crystal method; 10 mL of high-yield silver nanoplate solution was centrifuged twice at 8000 rpm; deionized water was added to a solution volume of 10 mL, and the concentration of the silver element was prepared to be 1 mmol / L The initial solution; Add 1mL of polyvinylpyrrolidone solution with a concentration of 50mmol / L and 500μL of ascorbic acid solution with a concentration of 100mmol / L to the initial solution in turn, stir fully to obtain a self-assembly solution; The silicon wafer was immersed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com