Multilayer nano-composite electrode for lithium ion battery and preparation method thereof

A lithium-ion battery and nanocomposite technology, which is applied in battery electrodes, nanotechnology for materials and surface science, nanotechnology, etc. problem, to achieve the effect of reducing irreversible capacity, increasing energy density, and reducing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation of a novel multilayer nanocomposite electrode for lithium ion batteries includes the following steps:

[0039] (1) Copper powder sintering: Weigh the copper powder and place it in a customized graphite mold, then place it in a vacuum resistance furnace and sinter it at a high temperature in a hydrogen environment. The sintering temperature is 900°C and the holding time is 2h;

[0040] (2) The growth of copper oxide nanoneedles: place the sintered sample in a muffle furnace and heat it at high temperature in the air at a heating temperature of 500°C and a holding time of 7 hours to obtain copper oxide with nanoneedles grown;

[0041] (3) Reduction of copper oxide nano-needles: Place the copper oxide with nano-needles in a vacuum resistance furnace, and reduce the copper oxide nano-needles in a hydrogen environment with a heating temperature of 250°C and a holding time of 2 hours to obtain a copper current collector ;

[0042] (4) Deposition of silicon nano-layer:...

Embodiment 2

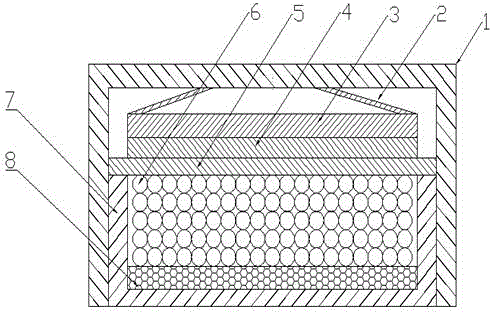

[0047] The multilayer nanocomposite electrode prepared in Example 1 is used to assemble a lithium-ion half-cell, and the assembly diagram is as follows image 3 As shown, it includes an upper battery shell 1, an elastic sheet 2, a gasket 3, a lithium sheet 4, a diaphragm 5, an electrolyte 6, a lower battery shell 7 and a novel multilayer nanocomposite electrode 8;

[0048] The multilayer nano composite electrode 8 is placed on the lower battery shell 7. The electrolyte 6 directly infiltrates the active material of the needle-shaped nano composite layer on the multilayer nano composite electrode 8, and the electrolyte 6 is filled with the multilayer nano composite electrode 8. The entire cavity formed by the shell 7 and the diaphragm 5; the lithium sheet 4 is tightly attached to the diaphragm 5, and the upper surface of the lithium sheet 4 is placed on the upper surface of the lithium sheet 4 sequentially from the bottom to the top with the gasket 3 and the elastic sheet 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com