Porous starch composite material, and preparation method and applications thereof

A porous starch and composite material technology, applied in the field of materials, can solve the problems of poor hemostatic effect, high preparation cost, difficult in vivo degradation, etc., achieve good biological activity and degradability, good biological activity, and promote blood coagulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

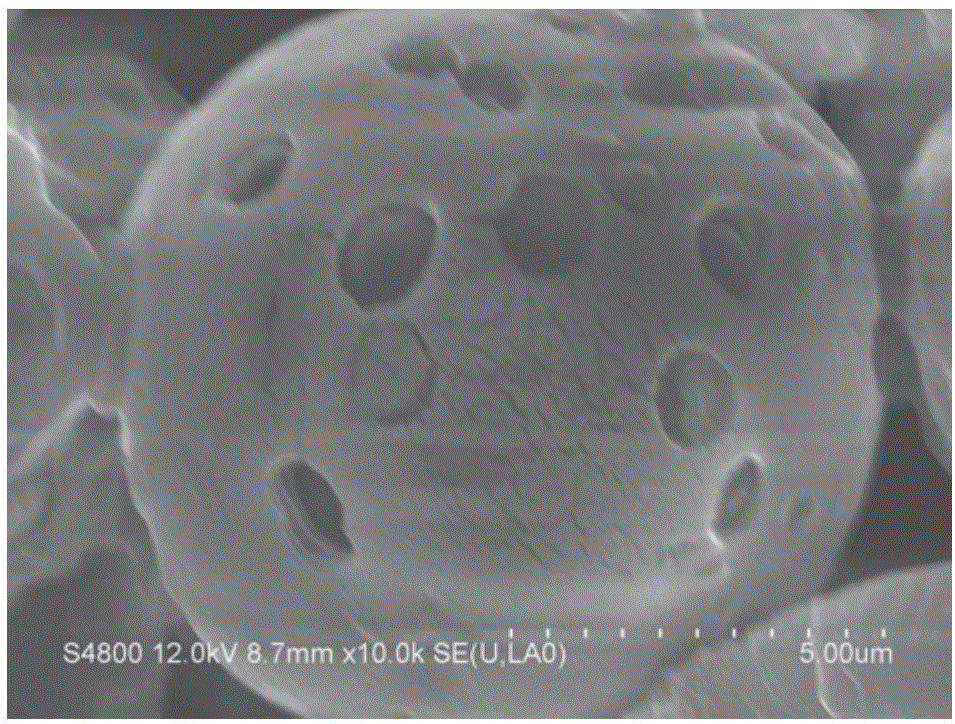

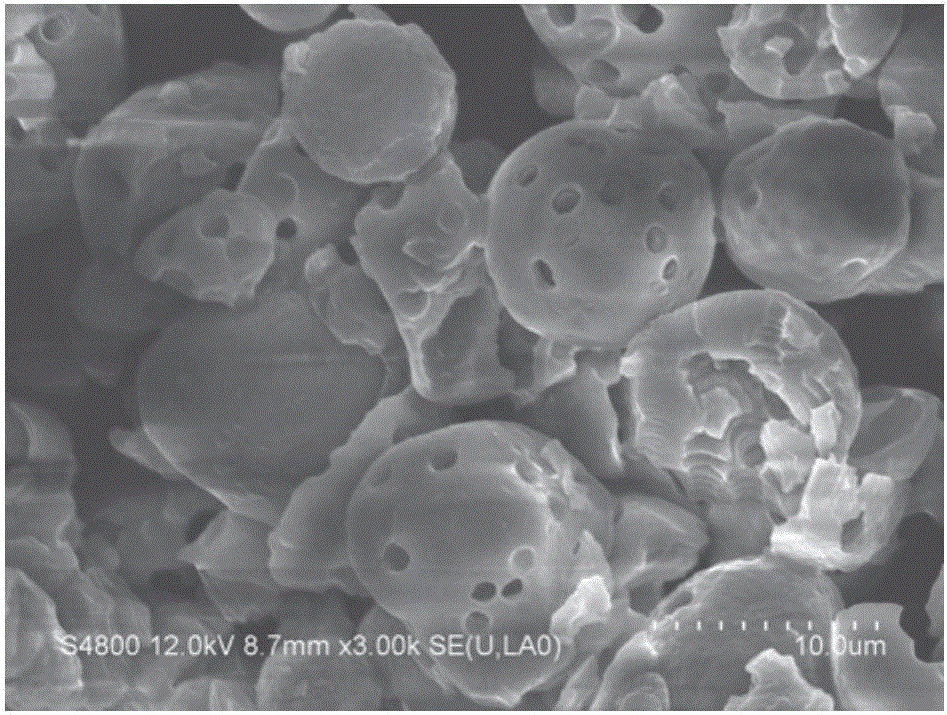

[0051] A preparation method of a porous starch / mesoporous calcium-zinc silicate composite hemostatic material, specifically completed according to the following steps:

[0052] (1) Preparation of porous starch

[0053] Add 100g of cornstarch, 2g of α-amylase, and 3g of glucoamylase into 250ml of phosphate buffer (sodium monohydrogen phosphate-phosphate buffer), stir at a temperature of 50°C and a pH of 5.8 to carry out the enzymolysis reaction , after 6 hours, centrifuged and dried to obtain porous starch;

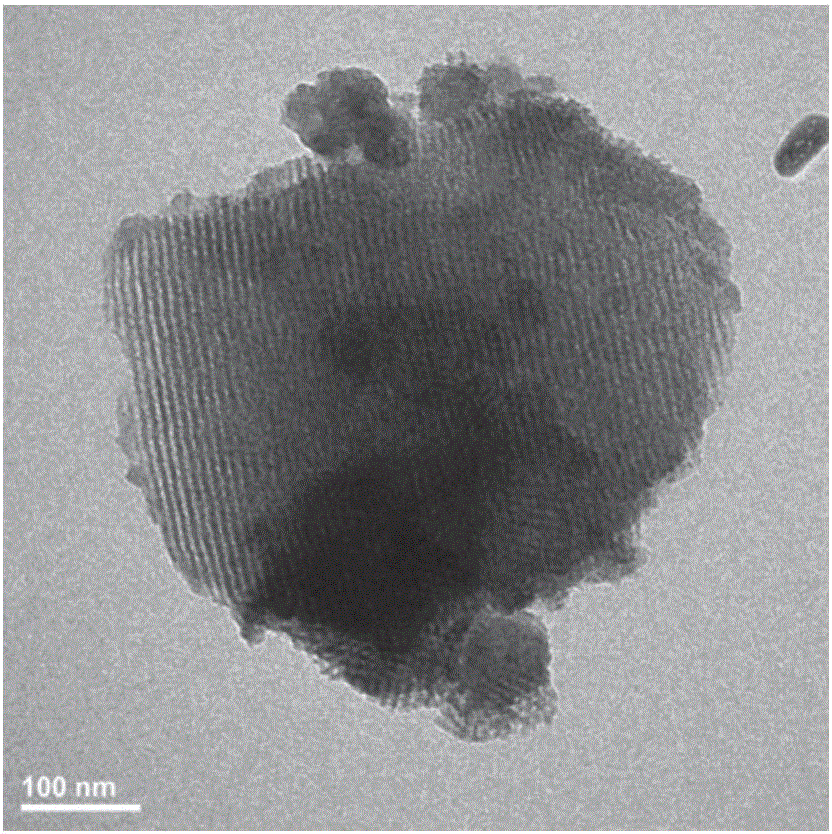

[0054] (2) Preparation of Mesoporous Calcium Zinc Silicate

[0055] In the mixture of 4.0g P123 and 30mL water, the temperature was controlled at 45°C, 120mL of 2mol / L hydrochloric acid was added and mixed evenly, then 15.8g of zinc nitrate hexahydrate and 10.71g of calcium nitrate tetrahydrate were added, and 9.12mL of TEOS was dissolved in 15 Add it dropwise into the solution at a rate of drop / min, stir for 12 hours until the solution becomes cloudy, and then continue ...

Embodiment 2

[0059] A preparation method of a porous starch / mesoporous calcium-zinc silicate composite hemostatic material, specifically completed according to the following steps:

[0060] (1) Preparation of porous starch

[0061] Add 100g of cornstarch, 2g of α-amylase, and 3g of glucoamylase into 250ml of phosphate buffer (sodium monohydrogen phosphate-phosphate buffer), stir at a temperature of 50°C and a pH of 5.8 to carry out the enzymolysis reaction After 9 hours, centrifuge and dry to obtain porous starch.

[0062] (2) Preparation of Mesoporous Calcium Zinc Silicate

[0063] In the mixture of 4.0g P123 and 30mL water, the temperature was controlled at 45°C, 120mL of 2mol / L hydrochloric acid was added and mixed evenly, then 17.6g of zinc nitrate hexahydrate and 11.76g of calcium nitrate tetrahydrate were added, and 9.12mL of TEOS was dissolved in 15 Add it dropwise into the solution at a rate of drop / min, stir for 12 hours until the solution becomes cloudy, and then continue to st...

Embodiment 3

[0067] A preparation method of a porous starch / mesoporous calcium-zinc silicate composite hemostatic material, specifically completed according to the following steps:

[0068] (1) Preparation of tapioca starch

[0069] Add 100g of tapioca starch, 2g of β-amylase, and 3g of debranching enzyme into 500ml of phosphate buffer (sodium monohydrogen phosphate-phosphate buffer), stir at a temperature of 50°C and a pH of 5.8 to carry out the enzymolysis reaction After 6 hours, centrifuge and dry to obtain porous starch.

[0070] (2) Preparation of Mesoporous Calcium Zinc Silicate

[0071] In the mixture of 4.0g P123 and 30mL water, control the temperature at 45°C, add 120mL of 2mol / L hydrochloric acid and mix well, then add 13.1g of zinc nitrate hexahydrate and 9.761g of calcium nitrate tetrahydrate, and dissolve 9.12mL of TEOS in 15 Add it dropwise into the solution at a rate of drop / min, stir for 12 hours until the solution becomes cloudy, and then continue to stir to obtain a sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com