Calcium carbonate D3 chewable tablets for children calcium supplement, and preparation method of chewable tablets

A technology of calcium carbonate and chewable tablets, applied in the field of pharmaceutical preparations, can solve the problems of inconvenience for children to chew and take, astringent taste and gritty feeling, complicated preparation process, etc., and achieves good quality stability, alleviating gritty feeling, and production process operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

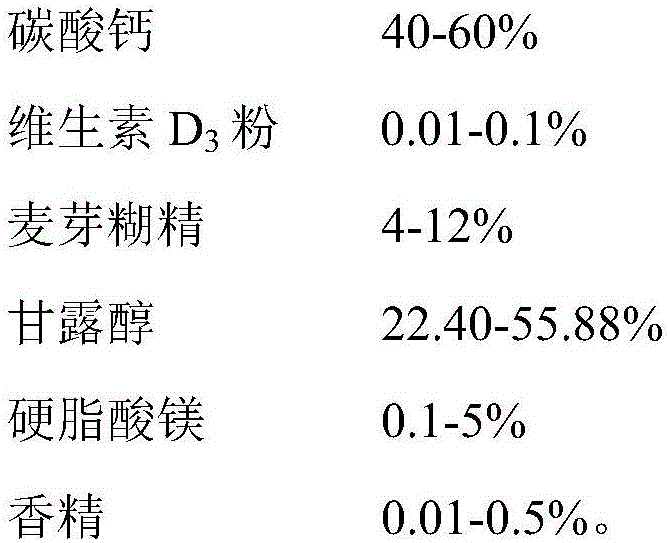

[0037] Calcium Carbonate D 3 Chewable tablets are composed of the following components by mass percentage:

[0038]

[0039] The required raw and auxiliary materials have passed the inspection, vitamin D 3 The powder is passed through a 60-mesh sieve, mannitol and magnesium stearate are passed through a 80-mesh sieve; the calcium carbonate is made into a 70% suspension, and the maltodextrin is made into a 50% aqueous solution, and then the two are mixed evenly ; Calcium carbonate and malt paste mixed solution (solid content about 66%) are spray-dried to make calcium carbonate maltodextrin embedment particles using a pressure atomizer; the aperture of the atomizer is 4mm, and the air inlet temperature is 140 °C, the exhaust air temperature is 105 °C; after drying, the granules are sieved with a 40-mesh sieve; vitamin D 3 The powder and mannitol are mixed evenly by equal amount addition method; put the granulated calcium carbonate maltodextrin embedding particles in the squ...

Embodiment 2

[0041] Calcium Carbonate D 3 Chewable tablets are composed of the following components by mass percentage:

[0042]

[0043]

[0044]The required raw and auxiliary materials have passed the inspection, vitamin D 3 The powder is passed through a 60-mesh sieve, mannitol and magnesium stearate are passed through a 80-mesh sieve; the calcium carbonate is made into a 70% suspension, and the maltodextrin is made into a 50% aqueous solution, and then the two are mixed evenly ; Calcium carbonate and malt paste mixed solution (solid content about 66%) are spray-dried to make calcium carbonate maltodextrin embedment particles using a pressure atomizer; the aperture of the atomizer is 4mm, and the air inlet temperature is 135 °C, the exhaust air temperature is 100 °C; after drying, the granules are sieved with a 40-mesh sieve; vitamin D 3 The powder and mannitol are mixed evenly by equal amount addition method; put the granulated calcium carbonate maltodextrin embedding particles...

Embodiment 3

[0046] Calcium Carbonate D 3 Chewable tablets are composed of the following components by mass percentage:

[0047]

[0048] The required raw and auxiliary materials have passed the inspection, vitamin D 3 The powder is passed through a 60-mesh sieve, mannitol and magnesium stearate are passed through a 80-mesh sieve; the calcium carbonate is made into a 70% suspension, and the maltodextrin is made into a 50% aqueous solution, and then the two are mixed evenly ; Calcium carbonate and malt paste mixed solution (solid content about 65%) are spray-dried to make calcium carbonate maltodextrin embedment particles using a pressure atomizer; the aperture of the atomizer is 4mm, and the air inlet temperature is 130 °C, the exhaust air temperature is 95 °C; after drying, the granules are sieved with a 40-mesh sieve; vitamin D 3 The powder and mannitol are mixed evenly by equal amount addition method; put the granulated calcium carbonate maltodextrin embedding particles in the squa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com