mofs-crosslinked polyethylene glycol diacrylate mixed matrix film and its preparation and application

A technology of polyethylene glycol diacrylate and mixed matrix membranes, which is applied in membrane technology, carbon compounds, semipermeable membrane separation, etc., and can solve the problems of easy-to-produce defects, high gas permeability and separation selectivity, and limit industrial applications, etc. problem, to achieve the effect of increased permeability and separation selectivity, significant industrial application prospects, simple and easy operating conditions and synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

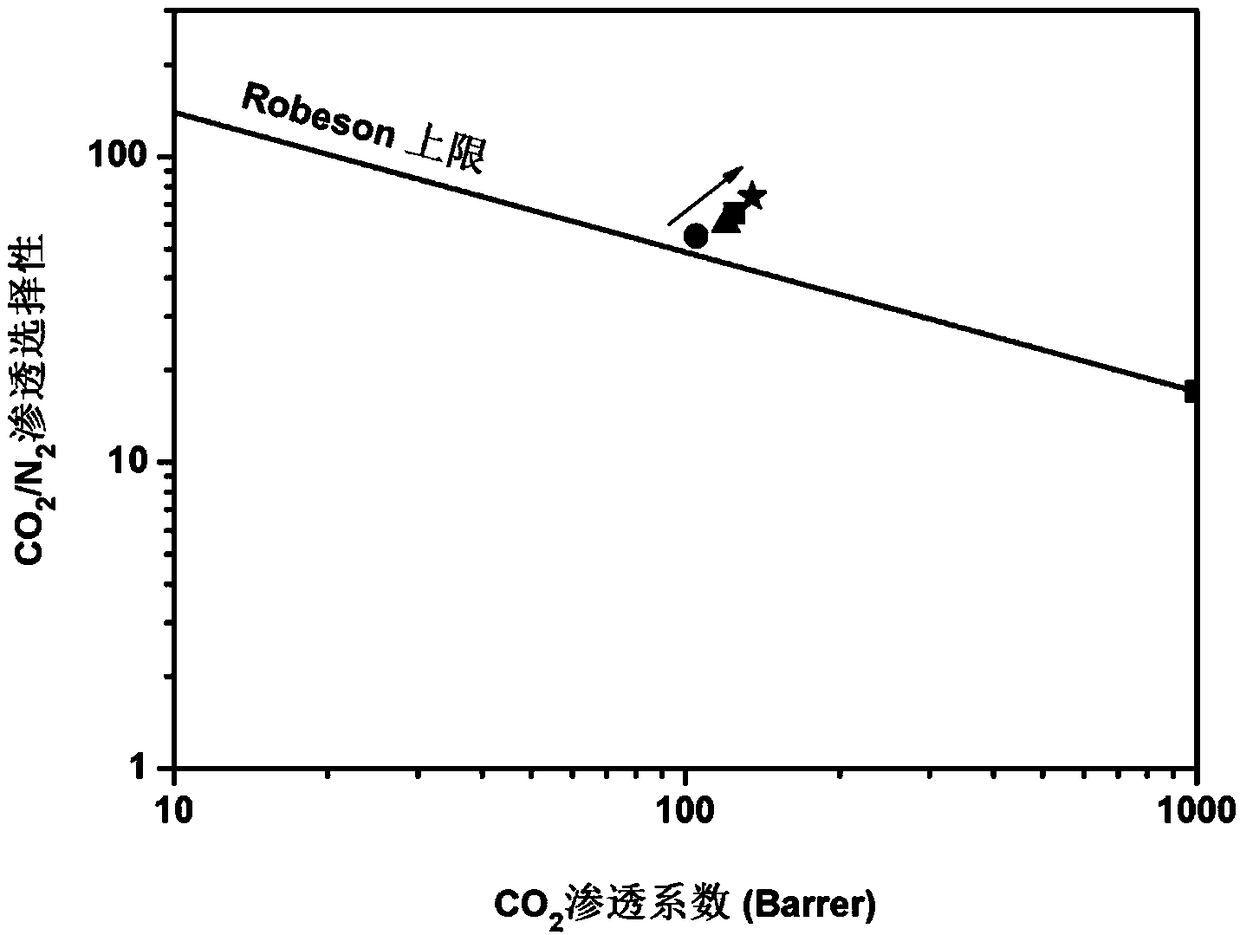

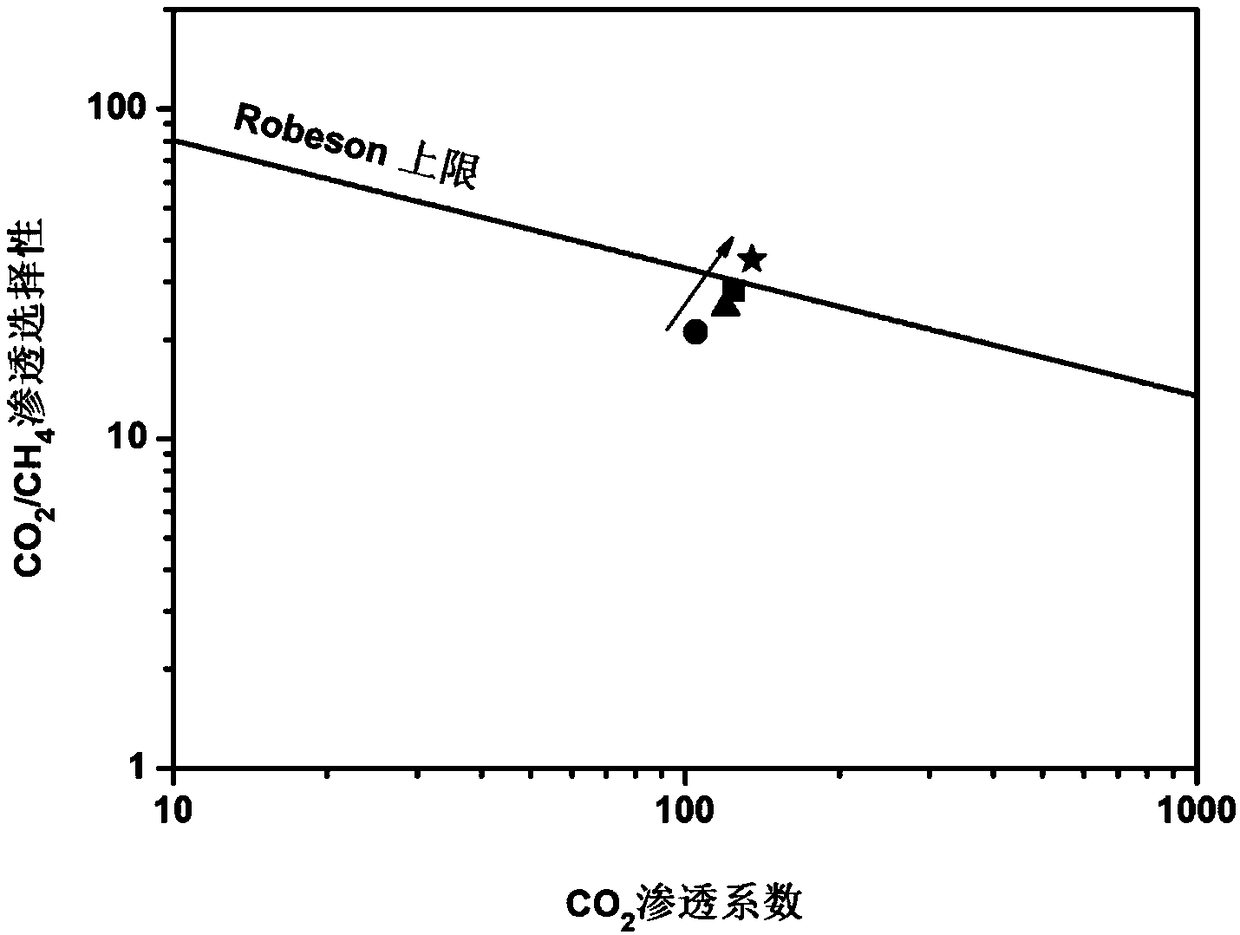

Embodiment 1

[0035] Add 2 g of PEGDA-700 and 0.002 g of benzoin dimethyl ether into 2 g of isopropanol solution, stir to dissolve completely. Then, 0.2 g of ZIF-11 nanoparticles were added into the above polymer solution, and ultrasonicated for 30 minutes to prepare a uniform casting solution. Then stand still for 12 hours for degassing, pour the casting solution between two quartz plates to control the thickness of 100 μm, put it in an ultraviolet crosslinker for 90 seconds (wavelength 312nm) to form a solid film, and then soak in isopropanol for 3 days. Then put it into a vacuum drying oven, vacuumize at 20°C for 12h, then raise the temperature to 50°C and dry for 48h, further remove the residual solvent, and finally obtain a mixed matrix film with a mass fraction of ZIF-11 of 10%. It has been determined that under the conditions of 35°C and 1MPa, CO 2 , N 2 、CH 4 The permeability coefficients are: 125, 2.0, 4.8Barrer; separation selectivity: α CO2 / N2 =61,α CO2 / CH4 =26.

Embodiment 2

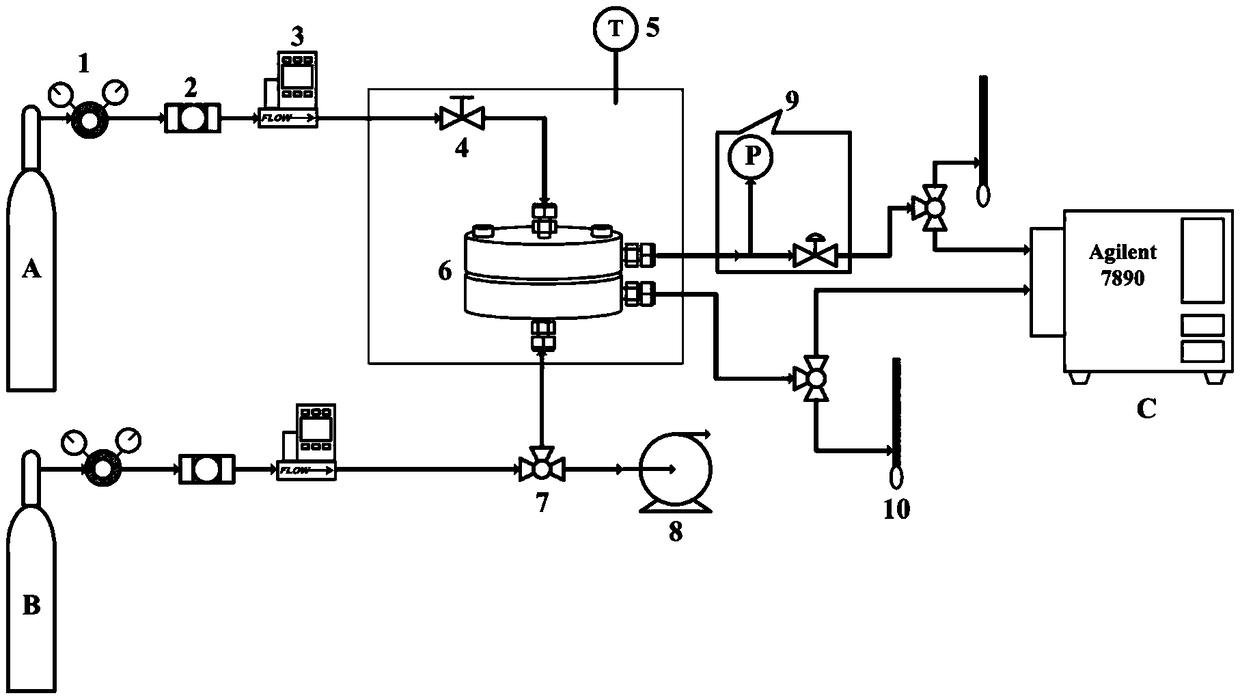

[0039] Add 2 g of PEGDA-700 and 0.006 g of HCPK into 2 g of ultrapure water, stir to dissolve completely. Then, 0.2, 0.5, 0.9, and 2 grams of ZIF-7 were added to four identical polymer solutions, ultrasonicated for 10 minutes, followed by degassing under negative pressure for 10 minutes to prepare a casting solution. Irradiate four parts of the casting solution with ultraviolet crosslinking method for 180s to make a solid film, and then soak it in water for 5 days; then put it in a vacuum drying oven, vacuumize it at 20°C for 48h, then raise the temperature to 80°C and dry it for 48h , to further remove the residual solvent, and finally obtain ZIF-7 / cross-linked polyethylene glycol diacrylate mixed matrix films with different mass fractions, and the thickness of the film is 200 μm. Under the conditions of 35°C and 1MPa, the CO of the membrane was tested by a gas permeation device 2 , N 2 、CH 4 Permeability, membrane performance data are shown in Table 1.

[0040] Table 1 ...

Embodiment 3

[0044] Add 2 grams of PEGDA-700 and 0.004 grams of HCPK into 2 grams of solvent (water, methanol and isopropanol, respectively), and stir to dissolve completely. Then add three parts of 0.2 grams of ZIF-90 to the polymer solutions of the above three different solvents, ultrasonically 30min to prepare the casting solution, then let it stand for 12h to defoam, and irradiate the casting solution with ultraviolet crosslinking 150s to form a solid film, and then immersed in the respective solvents for 5 days; then put it into a vacuum drying oven, vacuumize at 30°C for 12h, then raise the temperature to 50°C and dry for 12h, further remove the residual solvent, and finally get ZIF- The mass fraction of 90 is 10% mixed matrix membrane, and the thickness of the membrane is 100 μm. It has been determined that, under the conditions of 35°C and 1MPa, the CO of the membrane is tested by a gas permeation device. 2 , N 2 、CH 4 Permeability, membrane performance data are shown in Table 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com