Molecular sieve type solid acid catalyst for ethanol dehydration to ethylene and preparation and application thereof

A solid acid catalyst, ethanol dehydration technology, applied in molecular sieve catalysts, including molecular sieve catalysts, catalysts and other directions, can solve the problems of high ethanol raw material concentration requirements, harsh reaction conditions, high energy consumption and cost, and achieve high catalytic activity and selection. performance, low cost, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

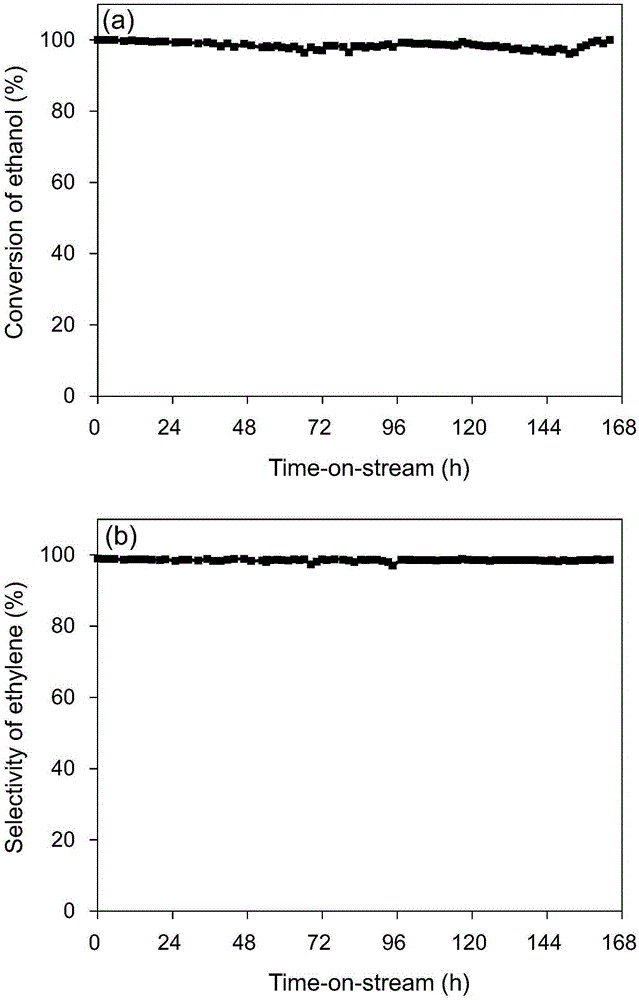

Image

Examples

Embodiment 1

[0021] Catalyst preparation

[0022] The ferric nitrate solution and the synthetic solution of hydrogen ZSM-5 molecular sieve are uniformly mixed under stirring, wherein, the Fe in the ferric nitrate solution 2 o 3 The mass ratio to molecular sieve is 0.1wt%; the above mixture is placed in a hydrothermal synthesis kettle for hydrothermal crystallization reaction at 150°C for 3 days, and dried at 100°C for 5h after hydrothermal crystallization; after the above drying The material was calcined at 400°C for 4 hours in a muffle furnace, and then fully ion-exchanged with a large amount of ammonium nitrate solution. After the ion exchange, it was calcined at 400°C for 4 hours in a muffle furnace to obtain a solid acid FeZSM-5 modified catalyst.

Embodiment 2

[0024] Catalyst preparation:

[0025] Mix the ferric sulfate solution and the synthetic solution of the hydrogen type ZSM-5 molecular sieve evenly under stirring, wherein, the Fe in the ferric nitrate solution 2 o 3 The mass ratio to molecular sieves is 2wt%; the above mixture is placed in a hydrothermal synthesis kettle for hydrothermal crystallization reaction at 160°C for 5 days, and dried at 120°C for 7h after hydrothermal crystallization; the above dried substance Put it in a muffle furnace and roast at 450°C for 5 hours, carry out sufficient ion exchange with an amount of ammonium nitrate solution, and after ion exchange, roast it in a muffle furnace at 450°C for 5 hours to obtain a solid acid FeZSM-5 modified catalyst.

Embodiment 3

[0027] Catalyst preparation:

[0028] Mix the ferric sulfate solution and the synthetic solution of the hydrogen type ZSM-5 molecular sieve evenly under stirring, wherein, the Fe in the ferric nitrate solution 2 o 3 The mass ratio to molecular sieves is 10wt%; the above mixture is placed in a hydrothermal synthesis kettle for hydrothermal crystallization reaction at 170°C for 7 days, and dried at 150°C for 10h after hydrothermal crystallization; the above dried substance Place it in a muffle furnace for 6 hours at 500°C, carry out sufficient ion exchange with a large amount of ammonium nitrate solution, and after ion exchange, place it in a muffle furnace for 6 hours at 500°C to obtain a solid acid FeZSM-5 modified catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com