Anion exchange resin for decoloring and deacidifying of high-quality juice

An exchange resin, high-quality technology, applied in the direction of anion exchange, ion exchange, coating, etc., can solve the problem of weak deacidification ability, achieve the effect of good regeneration, strong decolorization and deacidification ability, and reduce purchase cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Preparation of water phase: First add 8 parts of polyvinyl chloride paste resin and 3 parts of water-soluble chitosan to 250 parts of water, fully disperse and let stand for 30 minutes, then heat to 75-80 ° C and mix for 10 minutes, then add 5 parts of polyaluminum chloride and 0.5 parts of polyaspartic acid, continue to heat to reflux state and mix for 10 minutes, the resulting mixture is cooled to -5-0°C within 5 minutes in an ice-salt bath, and at -5-0°C Insulate and mix for 10 minutes, and finally homogenize the mixture twice at a homogenization temperature of 65-70°C and a homogenization pressure of 20-25MPa to obtain an aqueous phase solution;

[0022] (2) Preparation of the oil phase: first heat 60 parts of glycidyl methacrylate and 55 parts of hydroxyethyl methacrylate to 85-90 ° C and mix for 10 minutes, then add 30 parts of divinylbenzene, 20 parts of porogen Agent and 1 part of initiator, after fully mixing, microwave treatment at microwave frequency 2450...

Embodiment 2

[0028] (1) Preparation of water phase: first add 10 parts of polyvinyl chloride paste resin and 2 parts of water-soluble chitosan to 250 parts of water, fully disperse and let stand for 30 minutes, then heat to 75-80 ° C and mix for 10 minutes, then add 8 parts of polyaluminum chloride and 0.5 parts of polyaspartic acid, continue to heat to reflux state and mix for 10 minutes, the resulting mixture is cooled to -5-0 °C within 5 minutes under ice-salt bath, and at -5-0 °C Insulate and mix for 10 minutes, and finally homogenize the mixture twice at a homogenization temperature of 65-70°C and a homogenization pressure of 20-25MPa to obtain an aqueous phase solution;

[0029](2) Preparation of the oil phase: first heat 65 parts of glycidyl methacrylate and 50 parts of hydroxyethyl methacrylate to 85-90 ° C and mix for 10 minutes, then add 35 parts of divinylbenzene, 25 parts of porogen Agent and 2 parts of initiator, after fully mixing, microwave treatment at microwave frequency 2...

Embodiment 3

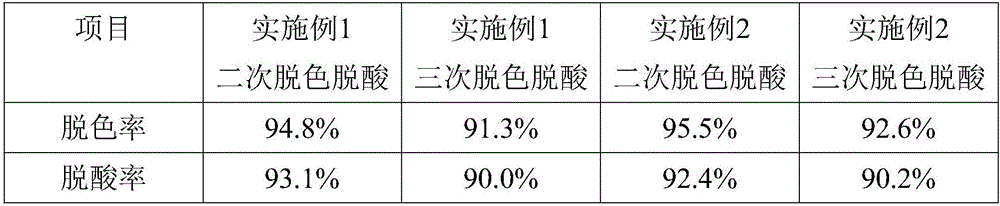

[0035] The same batch of fruit juices was evenly mixed and divided into four parts on average, and then decolorized by the resins prepared in Example 1 and Example 2 of the present invention, and commercially available D201 resin and D301 resin, and the decolorization rate and deacidification rate were measured. The results are shown in Table 1:

[0036] Table 1 Resin Decolorization and Deacidification Ability Determination

[0037] project Example 1 Example 2 D201 resin D301 resin Decolorization rate 99.1% 99.3% 93.5% 94.7% Deacidification rate 95.8% 96.4% 90.2% 91.1%

[0038] As can be seen from Table 1, the resins prepared in Example 1 and Example 2 of the present invention have a decolorization rate of more than 99% and a deacidification rate of more than 95% for fruit juice decolorization and deacidification, which are much higher than the currently commercially available food decolorization D201 Resin and D301 resin, so the decolor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com