A kind of rare earth butyl rubber and its preparation method

A butyl rubber and rare earth technology, applied in the field of rare earth butyl rubber and its preparation, can solve the problems of low production efficiency, short production cycle, high energy consumption, etc., and achieve the effects of low cost, extended production cycle and easy synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

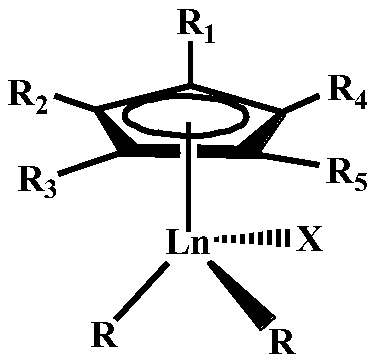

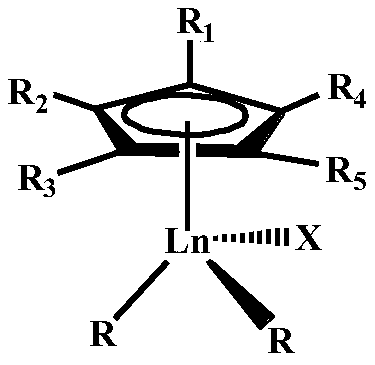

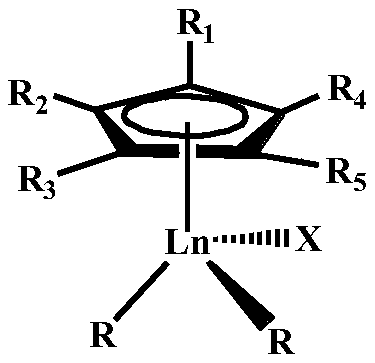

Image

Examples

Embodiment 1

[0012] Embodiment 1 monocyclocene dialkyl scandium complex (C 5 Me 4 SiMe 3 )Sc(CH 2 SiMe 3 ) 2 Preparation of (THF)

[0013] In the glove box, weigh 3.26g Sc(CH 2 SiMe 3 ) 3 (THF) 2 (7.25mmol) was put into a 100mL round bottom flask filled with a magnetic stirrer, and 10mL of n-hexane solvent was added to dissolve it. Weigh 1.41g trimethylsilyltetramethylcyclopentadiene C 5 Me 4 H(SiMe 3 ) (7.25mmol), dissolved with 1mL of n-hexane, and added dropwise to the reaction flask at room temperature. After stirring for 2 h, the solution was concentrated under reduced pressure to about 1 mL, left standing overnight at -35°C, and recrystallized to obtain 2.73 g of colorless crystals (C 5 Me 4 SiMe 3 )Sc(CH 2 SiMe 3 ) 2 (THF).

Embodiment 2

[0014] Embodiment 2 Preparation of isobutylene homopolymer

[0015] In a glove box under the protection of inert gas nitrogen, add 15ml of toluene solution to a 100ml stainless steel reaction kettle, use a low-temperature constant temperature bath to control the polymerization reaction temperature, the polymerization reaction temperature is -35°C, add 3.2g of isobutylene monomer, turn on the stirring, add The prepared catalyzer of above-mentioned embodiment 1, rare earth catalyst Sc consumption is 20umol, rare earth catalyst (C 5 Me 4 SiMe 3 )Sc(CH 2 SiMe 3 ) 2 (THF) and organoboron reagent [Ph 3 C][B(C 6 f 5 ) 4 ] molar ratio [Sc] / [B] is 1, after 60 minutes of polymerization reaction, methanol is added to terminate the reaction, the glue is post-treated, and the product is vacuum-dried. Analytical test: the number average molecular weight of isobutylene homopolymer is 13.47×10 4g / mol, molecular weight distribution HI is 1.85.

Embodiment 3

[0016] Embodiment 3 Preparation of isobutylene homopolymer

[0017] The polymerization temperature is -45°C, other polymerization conditions are the same as in Example 2, analysis and test: the number average molecular weight of the isobutylene homopolymer is 29.89×10 4 g / mol, molecular weight distribution HI is 1.61.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com