High-speed railway ballast track ballast bed surface cementing material

A technology for high-speed railways and cementing materials, which is applied in the field of cementing materials on the surface of ballasted track beds of high-speed railways, can solve the problems of reduced material properties, low strength, foaming, etc., and achieves good corrosion resistance, UV aging resistance, and fatigue resistance. The effect of good performance and good service condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

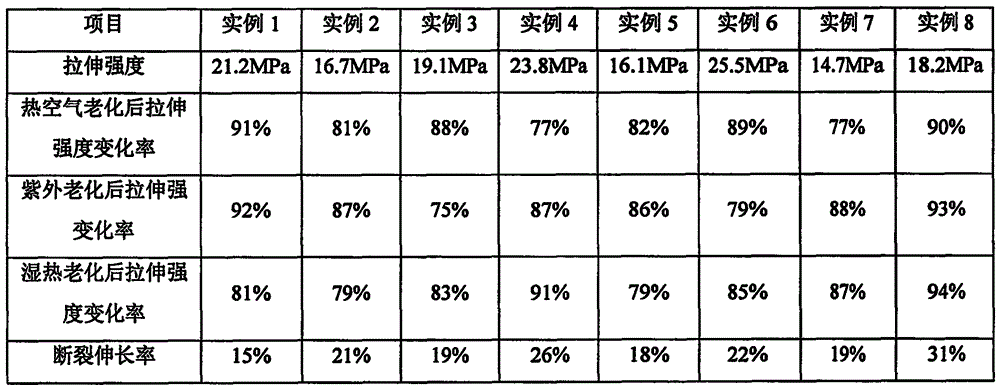

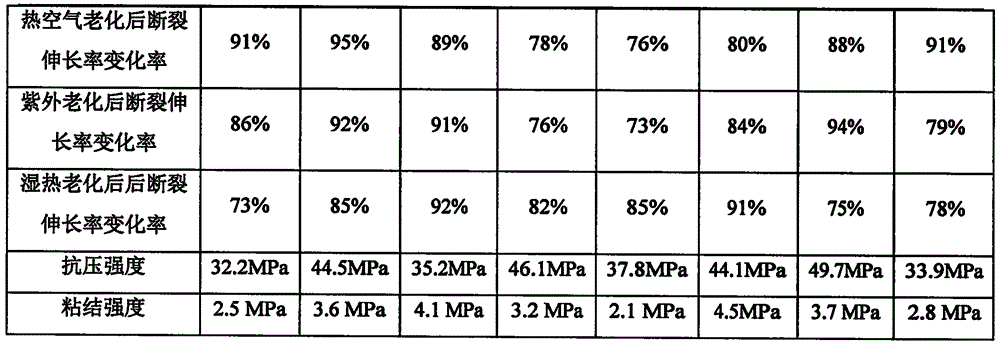

Examples

Embodiment 1

[0020] The composition of the cementing material on the surface of the ballast bed:

[0021] Part A is composed of the following raw materials in parts by weight: 100 parts of isocyanate composition, wherein 60 parts of MDI-50, 20 parts of PAPI, prepolymerization with NCO content of 15% prepared by MDI-100 and oleochemical polyether diol 10 parts of compound, 10 parts of prepolymer with NCO content of 20% prepared by IPDI and hydroxyl-terminated epoxidized polybutadiene, 5 parts of non-phthalate plasticizer, high solubility benzoate 5 parts of plasticizers, 2 parts of silane coupling agents containing isocyanate groups;

[0022] Part B consists of the following raw materials in parts by weight: 50 parts of high-activity polyether diol, 50 parts of high-activity polyether triol, 15 parts of ethylenediaminetetraether, 10 parts of MOCA, and 5 parts of triisopropanolamine grease , 5 parts of non-phthalate plasticizer, 5 parts of highly soluble benzoate plasticizer, 1 part of sili...

Embodiment 2

[0025] The composition of the cementing material on the surface of the ballast bed:

[0026] Part A is composed of the following raw materials in parts by weight: 100 parts of isocyanate composition, of which 30 parts of IPDI, 40 parts of carbodiamine modified MDI, NCO prepared from MDI-100 and tetrahydrofuran-propylene oxide copolyether diol 20 parts of a prepolymer with a content of 17.5%, 10 parts of a prepolymer with an NCO content of 16% prepared by IPDI and hydroxyl-terminated epoxidized polybutadiene, and 20 parts of a non-phthalate plasticizer , 10 parts of highly soluble benzoate plasticizers, 6 parts of silane coupling agents containing isocyanate groups;

[0027] Part B is composed of the following raw materials in parts by weight: 70 parts of high-activity polyether diol, 30 parts of high-activity polyether triol, 25 parts of ethylenediaminetetraether, 5 parts of MOCA, and 30 parts of triisopropanolamine grease , 20 parts of non-phthalate plasticizer, 10 parts of ...

Embodiment 3

[0030] The composition of the cementing material on the surface of the ballast bed:

[0031] Part A is composed of the following raw materials in parts by weight: 100 parts of isocyanate composition, wherein 50 parts of IPDI, 50 parts of a prepolymer with NCO content of 18% prepared by MDI-100 and hydroxyl-terminated epoxidized polybutadiene , 10 parts of non-phthalate plasticizers, 10 parts of highly soluble benzoate plasticizers, and 4 parts of silane coupling agents containing isocyanate groups;

[0032]Part B is composed of the following raw materials in parts by weight: 100 parts of high-activity polyether triol, 30 parts of ethylenediamine tetraether, 10 parts of MOCA, 5 parts of triisopropanolamine grease, non-phthalate ester 5 parts of plasticizer, 15 parts of highly soluble benzoate plasticizer, 1.5 parts of silicone defoamer, 2 parts of light stabilizer, 1 part of antioxidant, 0.5 part of hydrolysis stabilizer;

[0033] The volume ratio of A and B is 1:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com