Quasi-solid electrolyte film applied to electrochromism as well as preparation and application thereof

An electrolyte film and electrochromic technology, applied in applications, flat products, household appliances, etc., can solve problems such as easy leakage, poor chemical stability, and difficult packaging, and achieve the effects of improved performance, low cost, and controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] At room temperature, weigh 10.96g of dried lithium perchlorate and place it in a 250mL beaker, add 100mL of N,N-dimethylformamide and stir until the lithium perchlorate is completely dissolved, and prepare 1mol / L lithium perchlorate N,N-dimethylformamide solution, weighed 0.97g polyvinylidene fluoride and 0.03g nano-silicon dioxide and added to 2ml of the above solution, stirred evenly, and then stood for half an hour to prepare a slurry, and then the slurry The material was taken out, coated and placed on a glass substrate under a hot press, the temperature was set at 120°C, and the time was 10 minutes to prepare a transparent quasi-solid electrolyte film and assemble it into an electrochromic device.

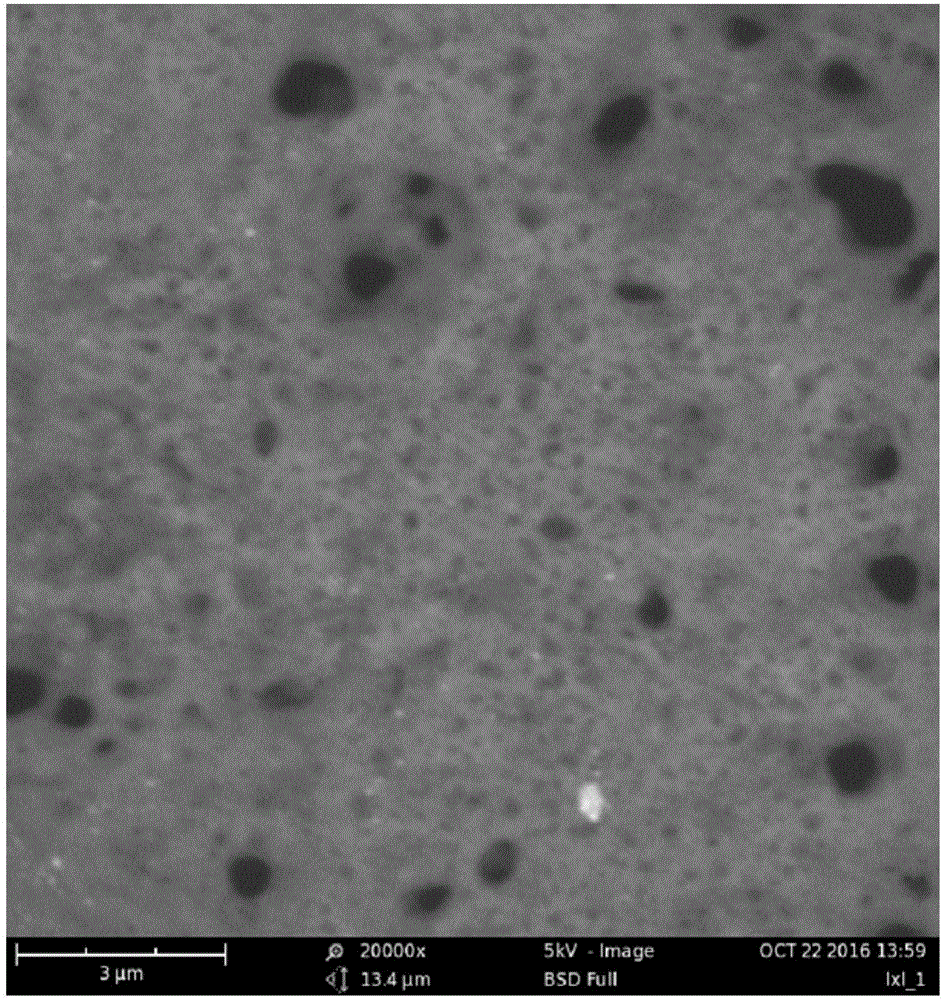

[0033] figure 1 The scanning electron micrograph of the prepared quasi-solid electrolyte film shows that the film has a porous structure and has a certain ability to store liquid electrolyte.

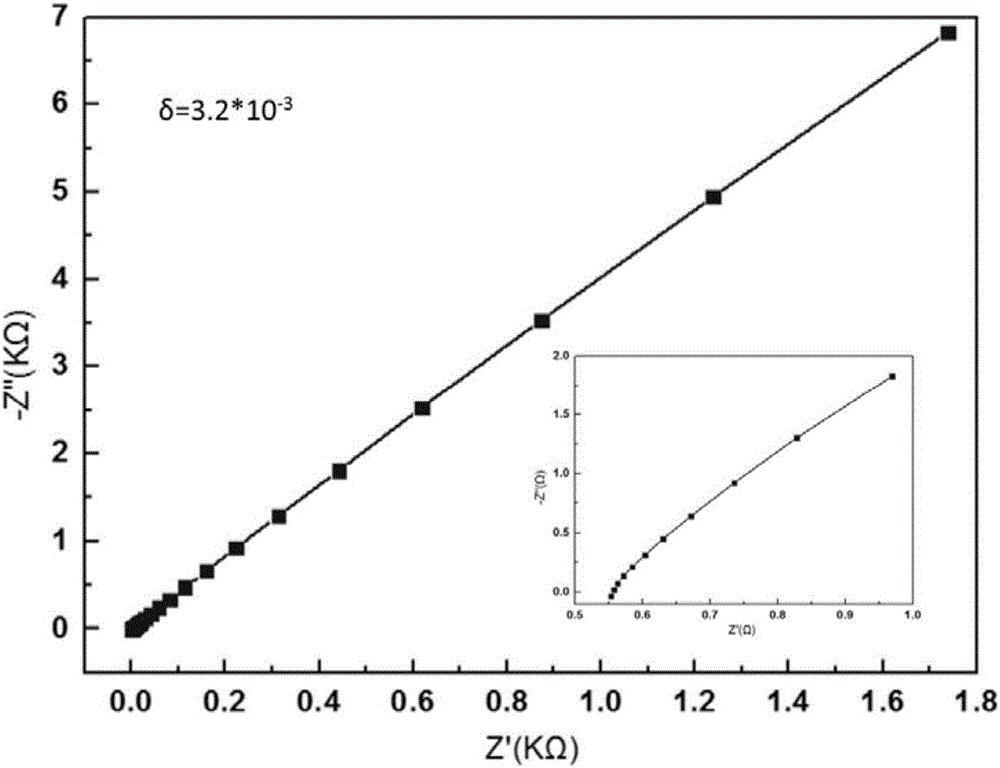

[0034] figure 2 It is the impedance test diagram of the electrolyte, and ...

Embodiment 2

[0038] At room temperature, weigh 10.96g of dried lithium perchlorate and place it in a 250mL beaker, add 100mL N,N-dimethylformamide and stir until lithium perchlorate is completely dissolved, and prepare 1mol / L lithium perchlorate N , N-dimethylformamide solution, weighed 0.89g of polyvinylidene fluoride and 0.11g of nano silicon dioxide and added to 2mL of the above solution, stirred evenly, and then stood for half an hour to prepare a slurry, and then the slurry Take out the coating and place it on the glass substrate under a hot press, set the temperature at 120°C, and press for 10 minutes to prepare a transparent quasi-solid electrolyte film, and assemble it into an electrochromic device.

[0039] Image 6 It is the impedance test chart of the electrolyte membrane, and the result shows that the conductivity of the electrolyte membrane is 1.91*10 ‐3 S / cm.

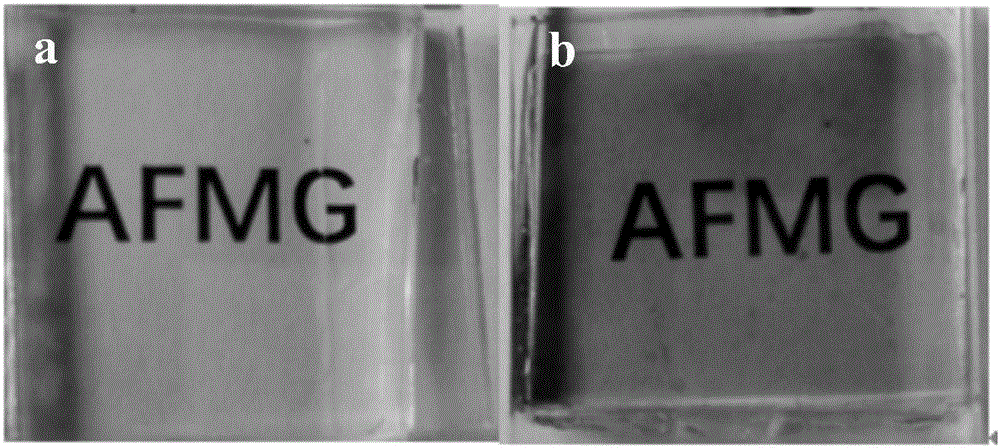

[0040] In order to understand the electrochromic performance of the quasi-solid electrolyte film prepared in the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com