Preparation method of sodium gold sulfide solution for cyanide-free gold plating

A gold sodium sulfite and cyanide-free gold plating technology, which is applied in chemical instruments and methods, inorganic chemistry, gold compounds, etc., can solve the problems of low conversion rate, low gold utilization rate, and low impurity content, and achieve stable separation, The effect of high utilization rate and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

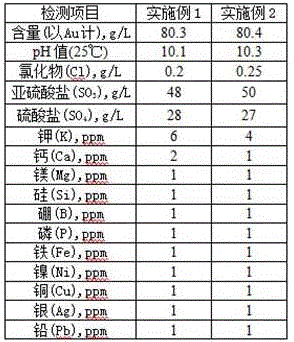

Examples

Embodiment 1

[0022] (1) Cut 8.2g of gold (containing 99.99% gold), slowly put it into a flask with an acid tail gas absorption device, add 50g of newly prepared aqua regia, slowly heat to 60°C under stirring, and keep warm until the gold is completely dissolved;

[0023] (2) Connect the decompression device, control the vacuum degree to be lower than -0.08Mpa, turn on the water bath for heating, control the above solution within 90°C and concentrate it under reduced pressure. When the distillation speed is slow, add 16g of hydrochloric acid in 3 times, Until no reddish-brown gas of nitrogen oxides is produced, continue to concentrate until the gold concentration in the solution is detected to be 48%, stop heating, cool to room temperature, and separate out chloroauric acid crystals;

[0024] (3) Add 24g of pure water to the chloroauric acid crystals to dissolve, adjust the gold concentration to 20%, add 54.7g of 30% sodium thiosulfate solution under stirring conditions, and stir at room tem...

Embodiment 2

[0029] (1) Cut 8.3g of gold (containing 99.99% gold), slowly put it into a flask with an acid tail gas absorption device, add 50g of newly prepared aqua regia, slowly heat to 55°C under stirring, and keep warm until the gold is completely dissolved;

[0030] (2) Connect the decompression device, control the vacuum degree to be lower than -0.08Mpa, turn on the water bath for heating, control the above solution to be concentrated under reduced pressure within 90°C, and when the distillation speed is slow, add 20g of hydrochloric acid in 4 times, Until no reddish-brown gas of nitrogen oxides is produced, continue to concentrate until the concentration of gold in the solution is detected to be 45%, stop heating, cool to room temperature, and separate out chloroauric acid crystals;

[0031] (3) Add 25g of pure water to the chloroauric acid crystals to dissolve, adjust the gold concentration to 20%, add 55g of 30% sodium thiosulfate solution under stirring conditions, stir and react ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com