Threaded twist joint type initiator and cracking device

A detonator and screw thread technology, applied in blasting barrels, weapon accessories, functional valve types, etc., can solve the problems of eliminating potential safety hazards, high manufacturing costs, and prone to squibs, and achieve the effect of avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

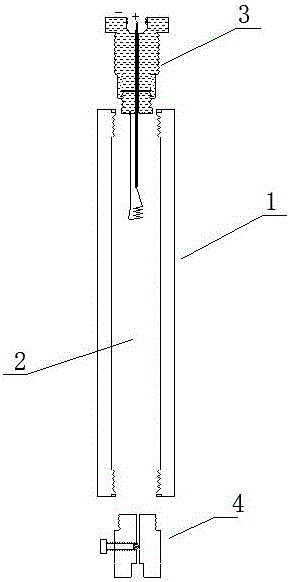

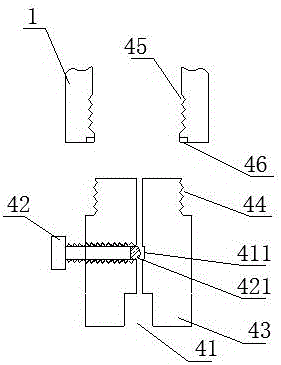

[0083] A threaded twist-on detonator, such as figure 1 As shown, it includes a housing 1, a filling chamber 2, an ignition mechanism 3 and an inflatable mechanism 4. The housing 1 is filled with a chamber 2, and the housing 1 is sealed to connect the ignition mechanism 3 and the inflatable mechanism 4. The pressure resistance of the housing 1 The strength is greater than 5.045Mpa; the shell 1 is a carbon steel cylinder or a stainless steel cylinder, and the inflation mechanism 4 and the ignition mechanism 3 are respectively connected to both ends of the shell 1; the filling chamber 2 is filled with a reducing agent and an oxidizing agent, and the oxidizing agent It is liquid oxygen, supercritical oxygen or high-pressure gaseous oxygen, and the reducing agent is carbon-containing organic matter or reducing element;

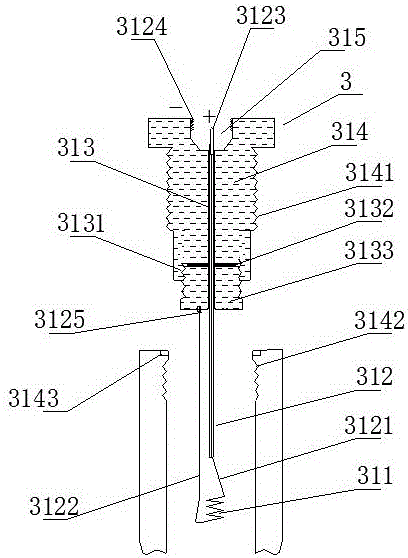

[0084] Such as figure 2As shown, the ignition mechanism 3 includes a heating wire 311, a wire 312, a wire perforation 313, a sealing base 314 and a screw hole gr...

Embodiment 2

[0095] The difference with embodiment 1 is: as Figure 4 As shown, the housing 1 includes a first segment body 11 and a second segment body 12, the first segment body 11 and the second segment body 12 are connected through a threaded structure, and are matched with a threaded sealing ring 13 for Sealing; the inflation mechanism 4 and the ignition mechanism 3 are respectively connected to both sides of the first segment body 11 and the second segment body 11; this structure is convenient for charging.

Embodiment 3

[0097] The difference with embodiment 1 is: as Figure 5 As shown, the housing 1 is a composite layer tube containing fiber material, the housing 1 is made of composite layers, the housing 1 includes a matrix layer 101, a fiber layer 102 and a hardened layer 103, and the hardened layer 103 is located at The outer layer of the fiber layer 102, the matrix layer 101 is located in the inner layer of the fiber layer 102; the two ends of the housing 1 are respectively sealed and wrapped with a first metal joint 111 and a second metal joint 112, and the first metal joint 111 and the second metal joint 112 are sealed and wrapped respectively. Two metal joints 112 are respectively connected to the inflation mechanism 4 and the ignition mechanism 3 ;

[0098] As a further description of the above embodiment, the base layer 101 is made of polyethylene (PE); the fiber layer 102 is made of glass fiber; the hardened layer 103 is made of epoxy resin.

[0099] As a further description of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com