Quantum conductance effect based memristor and preparation and modulation method and application thereof

A modulation method and memristor technology, applied in electrical components and other directions, can solve problems such as difficult control, reduced chip integration, and easy resistance drift, and achieve the effects of increasing device density, overcoming resistance drift, and increasing storage capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

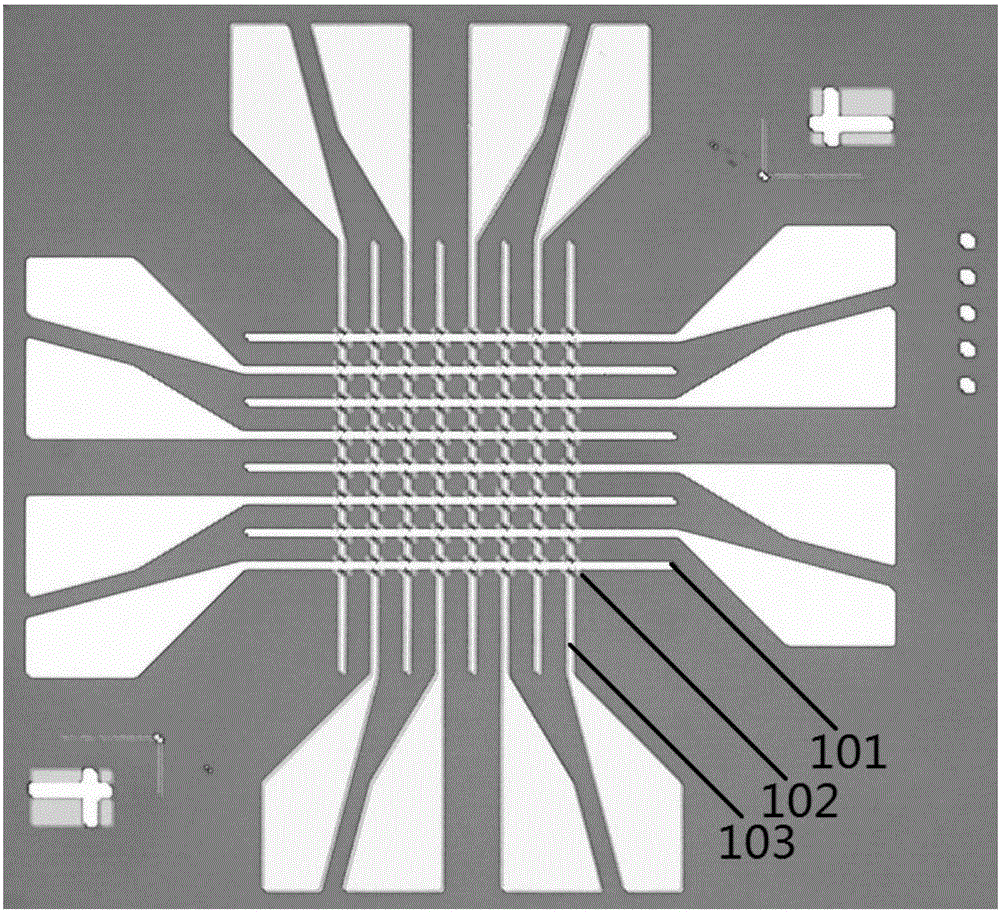

[0073] The memristor based on the quantum conductance effect provided in Example 1 is a Pt / HfO with an 8*8crossbar array structure x / Ti quantum conductance memristor, whose structure is as figure 1 shown; where the bottom electrode is Pt with a thickness of 150nm, and the functional layer is HfO with a thickness of 25nm x , 1.6<x<2; the upper electrode is Ti with a thickness of 150nm.

[0074] The following specifically describes the preparation method of the memristor based on the quantum conductance effect of embodiment 1; the specific steps are as follows:

[0075] (1) The first step:

[0076] (1.1) Photolithography: In the long thin SiO 2 One or more strip-shaped lower electrode patterns are prepared by a photolithography process on the Si substrate of the insulating layer;

[0077] Among them, the photolithography process includes: the steps of uniform glue, pre-baking, pre-exposure, post-baking, post-exposure, developing, coating, and stripping;

[0078] Sputtering...

Embodiment 2

[0097] The memristor based on the quantum conductance effect provided in Example 2 has a three-layer structure of a lower electrode, a functional layer and an upper electrode; wherein the material of the lower electrode is Pt with a thickness of 150nm; the functional layer is HfO with a thickness of 15nm x , 2<x<2.4; the upper electrode material is Ag, and the thickness is 150nm;

[0098] The following specifically describes the preparation method of the memristor based on the quantum conductance effect of embodiment 2; the specific steps are as follows:

[0099] (1) the first step;

[0100] Photolithography: The photolithography process has a total of eight steps: coating, pre-baking, pre-exposure, post-baking, post-exposure, development, coating, stripping, and photolithography to produce strip-shaped lower electrode patterns;

[0101] Sputtering: On the Si substrate with a thin SiO2 insulating layer, the Pt lower electrode is prepared by magnetron sputtering, with a thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com