Bulk-heterojunction perovskite thin film, production method thereof and solar cell

A solar cell and bulk heterojunction technology, applied in the field of solar cells, can solve the problems that are not conducive to large-scale production and yield control, increase the difficulty of perovskite film preparation, and film charge recombination, so as to avoid high temperature sintering process, Strong electron extraction ability, reducing the effect of charge recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

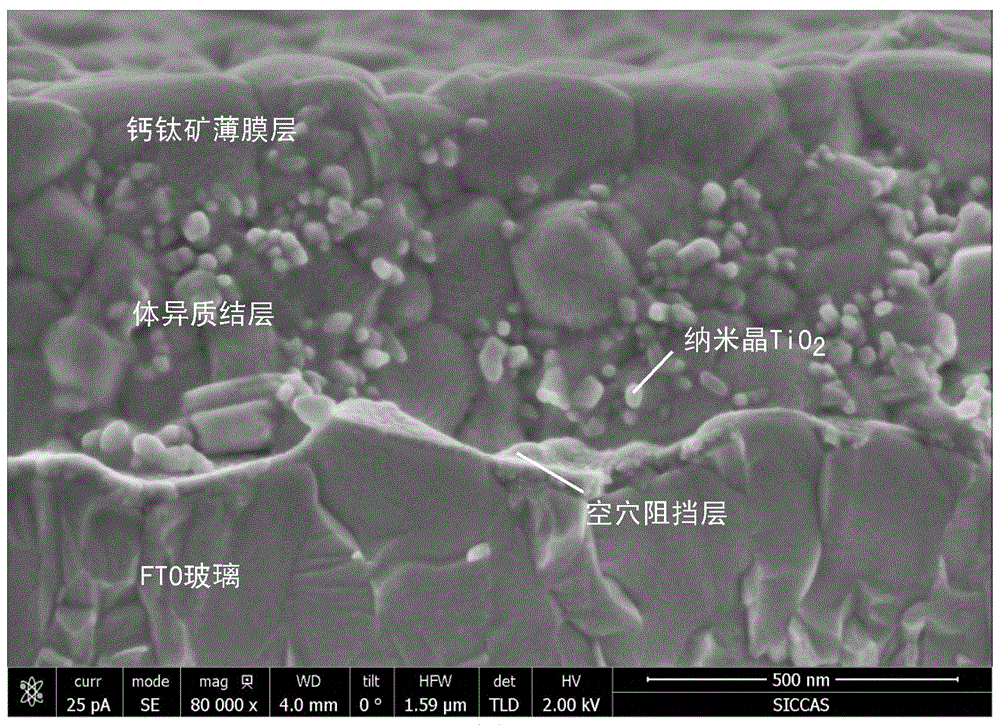

[0027] The invention relates to a bulk heterojunction perovskite film, a corresponding perovskite solar cell and a preparation method thereof. By coating the prepared perovskite precursor solution and perovskite / electron acceptor material dispersion on the substrate, a bulk heterojunction precursor film is formed, and by crystallizing the bulk heterojunction precursor film, The bulk heterojunction perovskite thin film of the present invention is obtained. The bulk heterojunction film of the present invention adopts perovskite material as the electron donor material, and the electron acceptor material is located at the grain boundary of the perovskite polycrystalline film, and a dense perovskite film layer is formed on the surface of the bulk heterojunction , compared with the traditional perovskite film, the preparation method is simpler, and the film quality is easier to control, which overcomes the problems of complex traditional structure and process and higher requirements...

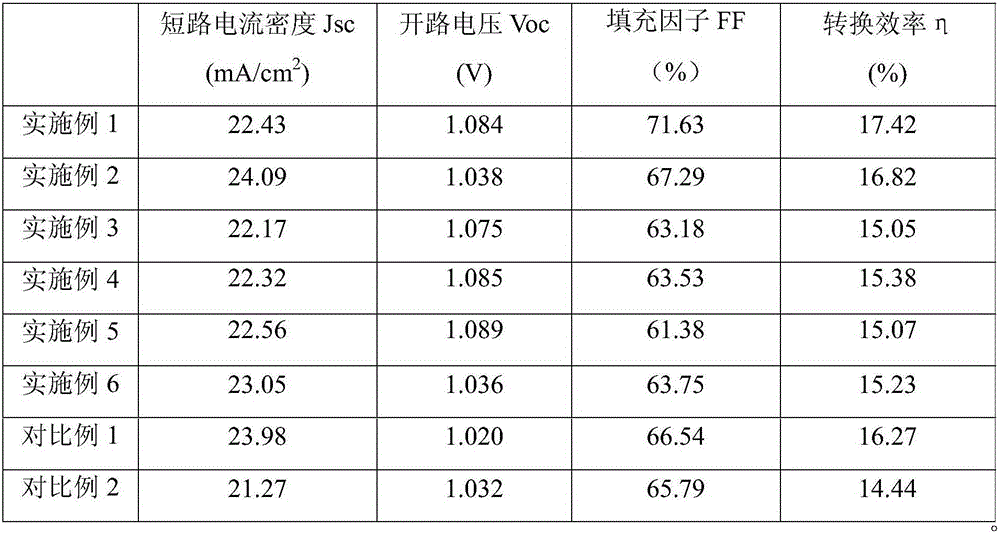

Embodiment 1

[0066] Synthesis of TiO by Hydrothermal Method 2 Nanocrystalline: Add 150mL tetrabutyl titanate into a glass reactor filled with 0.1moL / L dilute nitric acid solution (1000mL) under vigorous stirring, hydrolyze to form a white precipitate, then heat the reactor to 120°C and keep stirring Incubate for 8 hours to degumming and concentrate. The resulting sol was transferred into a titanium autoclave and subjected to hydrothermal treatment at 260 °C for 12 hours to obtain TiO 2 Nanocrystalline. Obtained TiO 2 The particle size of the nanocrystals is about 20nm;

[0067] (1) Preparation of perovskite / electron acceptor material dispersion. First prepare TiO 2 DMF dispersion: the hydrothermally synthesized TiO 2 The nanocrystals were washed with deionized water, ethanol and DMF to remove impurities, and then dispersed in DMF to form a dispersion liquid for later use. Then, the PbI 2 , MAI and DMSO were dissolved in DMF at a ratio of 1:1:1 and stirred thoroughly to obtain a per...

Embodiment 2

[0074] (1) Preparation of perovskite / electron acceptor material dispersion. First prepare TiO 2 DMF dispersion: the hydrothermally synthesized TiO 2 The nanocrystals were washed with deionized water, ethanol and DMF to remove impurities, and then dispersed in DMF to form a dispersion liquid for later use. Then, the PbI 2 , MAI and DMSO were dissolved in DMF at a ratio of 1:1:1 and stirred thoroughly to obtain a perovskite precursor solution (MAPbI 3 ), and then mix the perovskite precursor solution with TiO 2 DMF dispersion in a certain proportion (MAPbI 3 with TiO 2 Molar ratio is 10:1) mixed to obtain MAPbI 3 / TiO 2 Nanocrystalline precursor dispersion;

[0075] (2) Cleaning of the conductive substrate. With embodiment 1;

[0076] (3) Preparation of hole blocking layer. With embodiment 1;

[0077] (4) Preparation of perovskite heterojunction active layer. Dropwise addition of MAPbI on the substrate of FTO / hole blocking layer 3 / TiO 2 Nanocrystalline precursor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com