Foamed lithium-enriched manganese-based layered oxide and low-temperature fused salt preparation method

A technology rich in lithium manganese and oxides, applied in the field of lithium battery material preparation, can solve the problems of energy waste, slow conduction rate, long sintering time, etc., and achieve the effects of low reaction temperature, short time, and low energy consumption cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment is used to illustrate the sintering process of the electrode active material:

[0049] This implementation uses mixed lithium salts to sinter to prepare the electrode active material Li 1.2 mn 0.71 Ni 0.21

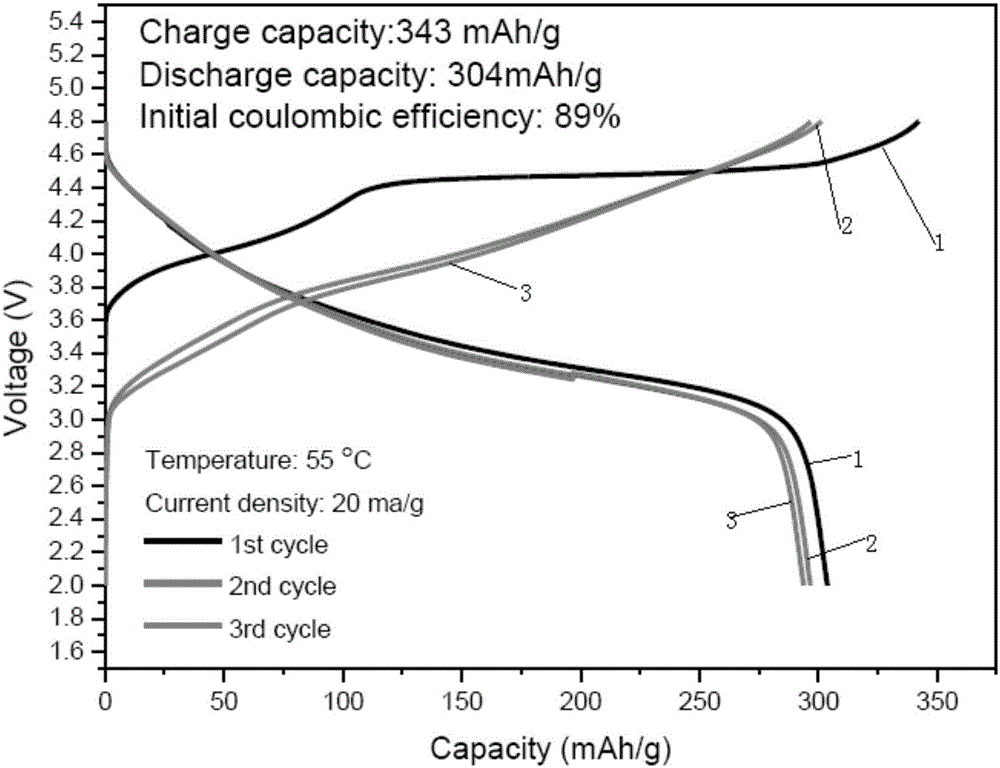

[0050] co 0.088 o 2 , the specific steps are: the foamed lithium-rich manganese-based layered oxide precursor Mn prepared by the co-precipitation method 0.71 Ni 0.21 co 0.088 (OH) 2 Mixed salt of powder and lithium hydroxide and lithium nitrate mixed in a certain proportion and then press Li 1.2 mn 0.71 Ni 0.21 co 0.088 o 2 The stoichiometric percentage of the mix. After mixing, treat at 250°C for 5 hours in an air atmosphere, then treat at 900°C for 10 hours after cooling, and then cool to room temperature. The resulting active substance Li 1.2 mn 0.71 Ni 0.21 co 0.088 o 2 products such as figure 1 , after grinding to obtain a powder for use, such as figure 2 . image 3 It is the XRD pattern of the obtained foamed lithium-rich...

Embodiment 2

[0052] This embodiment is used to illustrate the sintering process of the electrode active material:

[0053] This implementation uses mixed lithium salts to sinter to prepare the electrode active material Li 1.2 mn 0.71 Ni 0.21 co 0.088 o 2 , the specific steps are: the foamed lithium-rich manganese-based layered oxide precursor Mn prepared by the co-precipitation method 0.71 Ni 0.21 co 0.088 (OH) 2 Mixed salt of powder and lithium hydroxide and lithium nitrate mixed in a certain proportion and then press Li 1.2 mn 0.71 Ni 0.21 co 0.088 o 2 The stoichiometric percentage of the mix. After mixing, treat at 250°C for 5 hours in an air atmosphere, take it out of the furnace after cooling, and press it into a sheet of appropriate size in a mold, then treat at 900°C for 10 hours, and then cool to room temperature. After grinding, the resulting foamed lithium-rich manganese-based layered oxide Li 1.2 mn 0.71 Ni 0.21 co 0.088 o 2 .

Embodiment 3

[0055] This example is used to illustrate the preparation of electrode sheets and batteries.

[0056] Prepare the lithium-ion battery from the pressed and unpressed active materials in the above-mentioned sintering process. The specific steps are: the prepared electrode active material Li 1.2 mn 0.71 Ni 0.21 co 0.088 o 2 Mix the powder with acetylene black and binder PVDF in a weight ratio of 80:10:10, add an appropriate amount of NMP solution, stir in a dry environment at room temperature to form a slurry, and then evenly coat the slurry on the current collector aluminum foil respectively As the positive pole piece, it was dried at 100°C for 10 hours under empty conditions, and cut into pole pieces with a diameter of 10 mm after drying, weighed and recorded, and then transferred into a glove box for future use. The assembly of the simulated battery was carried out in an Ar atmosphere glove box, using 1M LiPF6 / EC+DEC (EC:DEC=1:1) solution as the electrolyte, and the negati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com