Method for preparing high-silicon aluminum alloy by peeling and thermal extruding through rapid-solidified powder metallurgy

A high-silicon aluminum alloy and powder metallurgy technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of interdiffusion barriers of alloying elements, difficulty in forming metallurgical bonding, and low cooling speed of alloys, and achieve high added value of products , large amount of powder deformation, and the effect of improving the mechanical properties of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

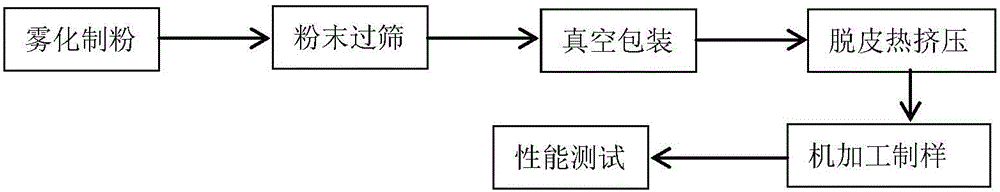

[0031] Example 1: Al-16Si-3.5Fe-2.3Cu-0.5Mg high silicon aluminum alloy

[0032] The high-silicon aluminum alloy powder is sieved, and the high-silicon aluminum alloy powder with a particle size of -150 mesh is selected, put into a pure aluminum sheath, and then the pure aluminum sheath is placed in the degassing furnace. The lower part is equipped with thermocouples to measure the temperature, and the vacuum unit is used for vacuum degassing, and the temperature is raised to 120°C at a rate of 20°C / 30min, and the temperature is kept for 120min to make the vacuum degree reach 8╳10 - 2 Pa; then raise the temperature to 240°C at a rate of 20°C / 30min, keep it warm for 210min, and make the vacuum degree reach 8╳10 -2 Pa; then raise the temperature to 340°C at a rate of 20°C / 30min, keep it warm for 180min, and make the vacuum degree reach 8╳10 -2 Pa; then raise the temperature to 440°C at a rate of 20°C / 30min, keep it warm for 180min, and make the vacuum degree reach 1╳10 -2 Pa;...

Embodiment 2

[0035] Example 2: Al-20Si-5Fe-4.3Cu-1.5Mg high silicon aluminum alloy

[0036] The high-silicon aluminum alloy powder is sieved, and the high-silicon aluminum alloy powder with a particle size of -200 mesh is selected, put into a pure aluminum sheath, and then the pure aluminum sheath is placed in the degassing furnace. The lower part is equipped with thermocouples to measure the temperature, and the vacuum unit is used for vacuum degassing, and the temperature is raised to 150°C at a rate of 20°C / 30min, and the temperature is kept for 120min to make the vacuum degree reach 8╳10 - 2 Pa; then raise the temperature to 250°C at a rate of 20°C / 30min, keep it warm for 210min, and make the vacuum degree reach 8╳10 -2 Pa; then raise the temperature to 350°C at a rate of 20°C / 30min, keep it warm for 180min, and make the vacuum degree reach 8╳10 -2 Pa; then raise the temperature to 450°C at a rate of 20°C / 30min, keep it warm for 180min, and make the vacuum degree reach 1╳10 -2 Pa; t...

Embodiment 3

[0039] Example 3: Al-23Si-4Fe-4.3Cu-1Mg high silicon aluminum alloy

[0040] The high-silicon aluminum alloy powder is sieved, and the high-silicon aluminum alloy powder with a particle size of -200 mesh is selected, put into a pure aluminum sheath, and then the pure aluminum sheath is placed in the degassing furnace. The lower part is equipped with thermocouples to measure the temperature, and the vacuum unit is used for vacuum degassing, and the temperature is raised to 150°C at a rate of 20°C / 30min, and the temperature is kept for 150min to make the vacuum degree reach 8╳10 - 2 Pa; then raise the temperature to 250°C at a rate of 20°C / 30min, keep it warm for 240min, and make the vacuum degree reach 8╳10 -2 Pa; then raise the temperature to 350°C at a rate of 20°C / 30min, keep it warm for 210min, and make the vacuum degree reach 8╳10 -2 Pa; then raise the temperature to 450°C at a rate of 20°C / 30min, keep it warm for 210min, and make the vacuum degree reach 1╳10 -2 Pa; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com