Dephosphorization method of chemical wastewater generated in process of producing hydrogen peroxide through anthraquinone method

A technology of chemical wastewater and hydrogen peroxide, which is applied in the field of environmental engineering, can solve the problems of difficult disposal of hazardous solid waste, large sedimentation volume, and high moisture content, and achieve good dehydration performance, small volume, and low moisture content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

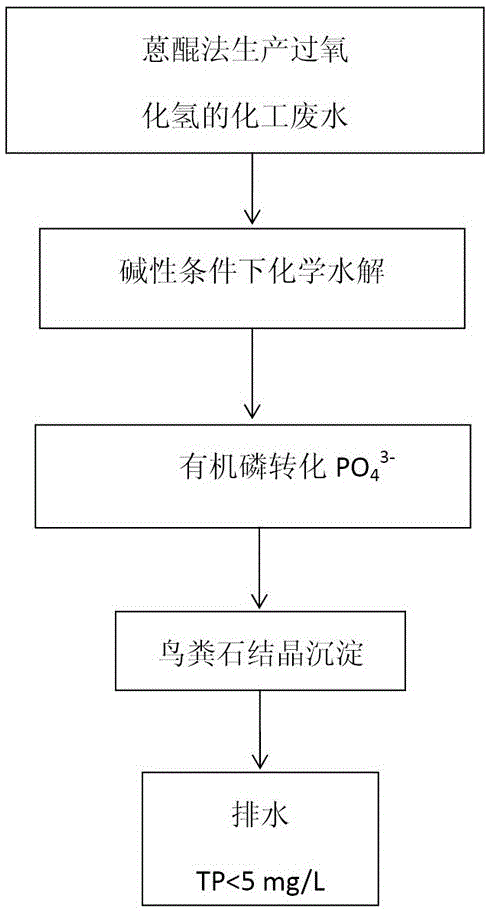

[0038] A kind of chemical industry waste water dephosphorization method that anthraquinone method produces hydrogen peroxide of the present invention, technological process is as figure 1 shown, including the following steps:

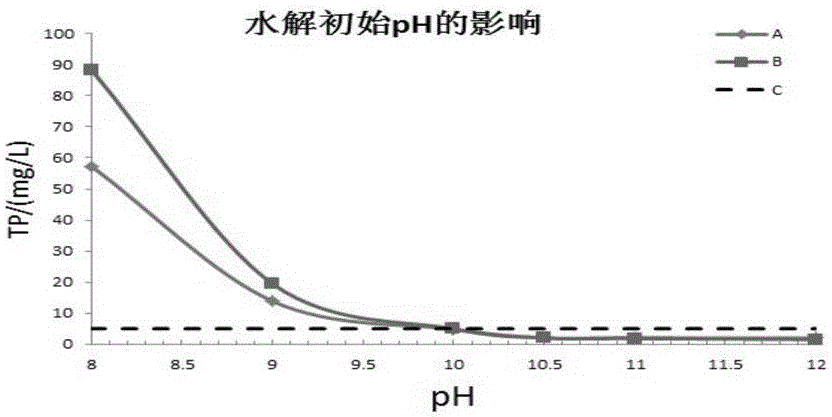

[0039] (1) Organic phosphorus is converted into inorganic PO 4 3- : Add sodium hydroxide to the chemical wastewater produced by anthraquinone method to produce hydrogen peroxide (the chemical wastewater contains organic phosphorus such as 172 mg / L trioctyl phosphate, and the total phosphorus is 228 mg / L) to adjust the pH of the chemical wastewater to 10, and carry out hydrolysis reaction , the temperature of the hydrolysis reaction is controlled at room temperature (28°C), the pH is 10.0, the time is 8 h, and the conversion of organic phosphorus to inorganic PO 4 3- The conversion rate is 99.5%.

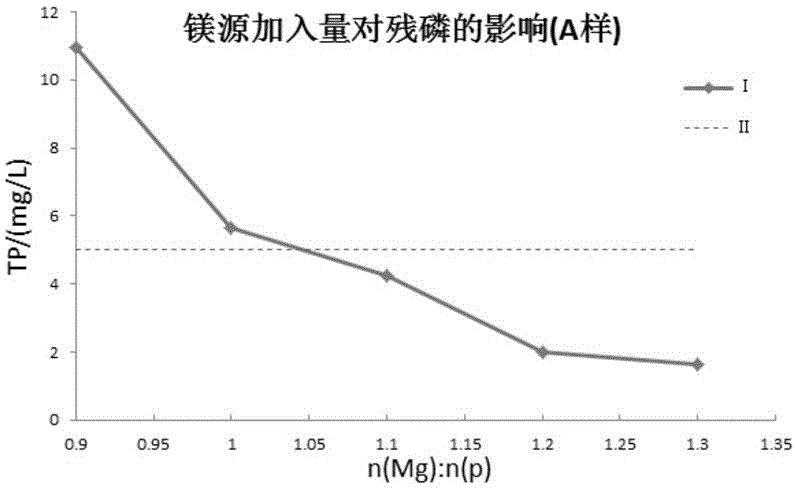

[0040] (2) Struvite crystallization: add ammonia salt and magnesium salt to the hydrogen peroxide production wastewater after the hydrolysis reaction in s...

Embodiment 2

[0042] A kind of chemical industry waste water dephosphorization method that anthraquinone method of the present invention produces hydrogen peroxide comprises the following steps:

[0043] (1) Organic phosphorus is converted into inorganic PO 4 3-: Add sodium hydroxide to the chemical wastewater produced by anthraquinone method to produce hydrogen peroxide (the chemical wastewater contains organic phosphorus such as 196 mg / L trioctyl phosphate, and the total phosphorus is 286 mg / L) to adjust the pH of the chemical wastewater to 10.5, and carry out hydrolysis reaction , control the temperature during the hydrolysis reaction to be 45°C, the pH to be 10.5, and the time to be 4 h to complete the conversion of organic phosphorus to inorganic PO 4 3- The transformation, its transformation rate is 99.2%.

[0044] (2) Struvite crystallization: add ammonia salt and magnesium salt to the hydrogen peroxide production wastewater after the hydrolysis reaction in step (1), and carry out...

Embodiment 3

[0046] A kind of chemical industry waste water dephosphorization method that anthraquinone method of the present invention produces hydrogen peroxide comprises the following steps:

[0047] (1) Organic phosphorus is converted into inorganic PO 4 3- : Add sodium hydroxide to the chemical wastewater produced by anthraquinone method to produce hydrogen peroxide (the chemical wastewater contains organic phosphorus such as 223 mg / L trioctyl phosphate, and the total phosphorus is 328 mg / L) to adjust the pH of the chemical wastewater to 11, and perform hydrolysis reaction, control the temperature during the hydrolysis reaction to be 35°C, the pH to be 11, and the time to be 10 h to complete the conversion of organic phosphorus to inorganic PO 4 3- The conversion, its conversion rate is 99.3%.

[0048] (2) Struvite crystallization: add ammonia salt and magnesium salt to the hydrogen peroxide production wastewater after the hydrolysis reaction in step (1), and carry out struvite cry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com