Tri-block hybrid fluorosilicone polymer and preparation method thereof

A fluorosilicone polymer and tri-block technology, applied in coatings and other directions, can solve problems such as large expansion coefficient and unsatisfactory surface energy, and achieve good adhesion and excellent surface inertness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

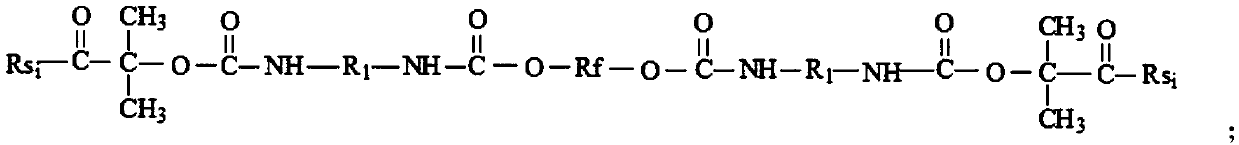

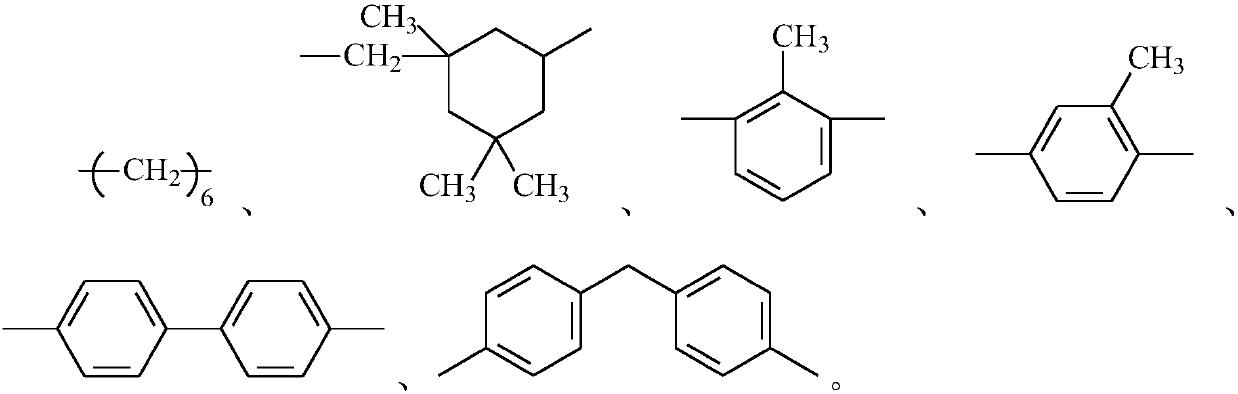

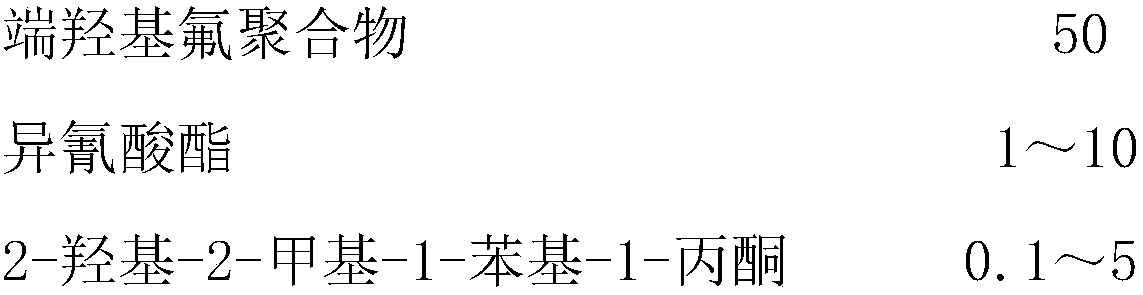

[0025] 50 parts of hydroxyl-terminated perfluoropolyether, 2 parts of isophorone isocyanate, 0.1 part of 2-hydroxy-2-methyl-1-phenyl-1-acetone, and 0.02 part of dibutyltin dilaurate are dissolved in the first part of acetone solvent (60 parts), add it to the reaction kettle, and react at a constant temperature of 80°C for a period of time. After the temperature drops to 60°C, quickly add the mixed solution of 50 parts of silane vinyl monomer and the second part of acetone solvent (40 parts), and pass through nitrogen gas After a period of time, photopolymerization is carried out under the irradiation of ultraviolet rays, etc., and the triblock hybrid fluorosilicone polymer is obtained as follows:

[0026]

[0027] After it is cured with KH550, the coating properties with good adhesion to PET film can be obtained as follows:

[0028]

Embodiment 2

[0030] 50 parts of hydroxyl-terminated VDF-HFP rubber, 3 parts of hexamethylene isocyanate, 0.6 part of 2-hydroxy-2-methyl-1-phenyl-1-acetone, 0.1 part of dibutyltin dilaurate are dissolved in the first part of ethyl acetate Add the ester solvent (50 parts) into the reaction kettle, and react at a constant temperature of 80°C for a period of time. After dropping to 60°C, quickly add the mixed solution of 50 parts of silane vinyl monomer and the second part of acetone solvent (50 parts), and pass through After entering nitrogen for a period of time, photopolymerization is carried out under the irradiation of ultraviolet light, etc., and the triblock hybrid fluorosilicon polymer is obtained as follows:

[0031]

[0032] Using AF and KH550 for dual curing, the properties obtained are as follows

[0033]

Embodiment 3

[0035] 50 parts of hydroxyl-terminated perfluoropolyether, 2 parts of isophorone isocyanate, 0.1 part of 2-hydroxy-2-methyl-1-phenyl-1-acetone, and 0.02 part of dibutyltin dilaurate are dissolved in the first part of acetone solvent (60 parts), add it to the reaction kettle, and react at a constant temperature of 80°C for a period of time. After dropping to 60°C, quickly add the mixed solution of 50 parts of fluorine-containing vinyl silane monomer and the second part of acetone solvent (40 parts), After passing nitrogen gas for a period of time, the photopolymerization reaction is carried out under the irradiation of ultraviolet light, etc., and the triblock hybrid fluorosilicon polymer is obtained as follows:

[0036]

[0037] Compared with Example 1, the surface was reduced to 9 mN / m due to the introduction of fluorine-containing vinyl silane. Its performance is as follows:

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com