Preparation method of NdFeB magnet powder

A technology of NdFeB and magnets, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of reduced magnetic properties of magnets, easy oxidation, etc., to improve remanence, increase orientation, strong The effect of antioxidant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

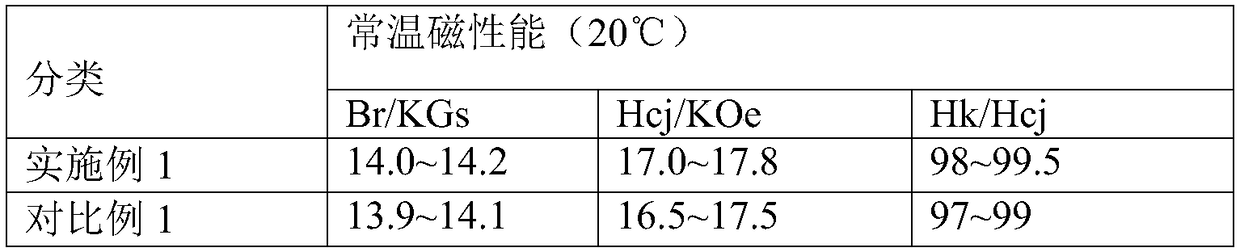

Embodiment 1

[0032] Validated with 50H sintered NdFeB material, the raw material composition is shown in Table 1 below:

[0033] element

[0034] First, according to the above formula, prepare 600Kg of raw materials, in which iron rods are derusted, rare earth materials are treated with oil-free, moisture-free and rust-free treatment, and the prepared raw materials are melted under the condition of medium frequency induction heating by vacuum melting (SC) , And finally obtain a sheet-like fast-quenched NdFeB alloy with columnar crystal structure.

[0035] Then, hydrogen is absorbed in a hydrogen crusher and crushed into millimeter-sized coarse particles. The medium crusher further crushes the particles, and then uses high-pressure nitrogen gas to grind uniform micron-sized powder with an average particle size of 4.0-4.5μm.

[0036] Then the jet mill powder is dehydrogenated and mechanically mixed through a dehydrogenation vessel, and the vacuum is evacuated to below 0.1Pa. The dehydrogenation ...

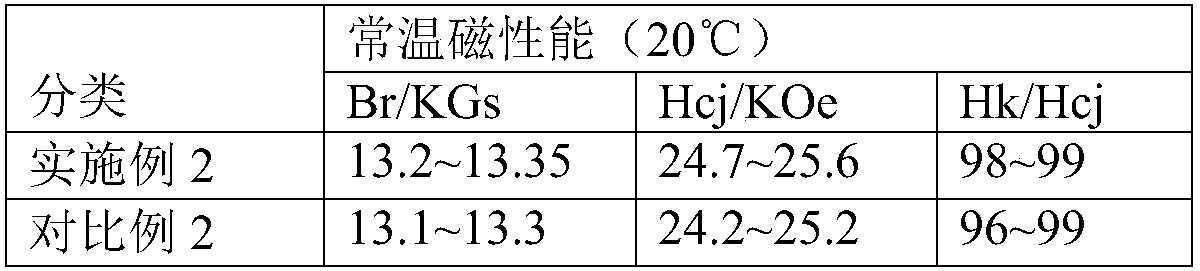

Embodiment 2

[0057] Validated with 42UH sintered NdFeB material, the raw material composition is shown in Table 6 below:

[0058] element

[0059] First, according to the above formula, prepare 600Kg of raw materials, in which iron rods are derusted, the rare earth materials are treated with oil-free, moisture-free and rust-free treatment, and the prepared raw materials are melted under the condition of medium frequency induction heating by vacuum melting (SC) , And finally obtain a sheet-shaped fast-quenched NdFeB alloy with columnar crystal structure.

[0060] Then, hydrogen is absorbed in a hydrogen crusher and crushed into millimeter-sized coarse particles. The medium crusher further crushes the particles, and then uses high-pressure nitrogen gas to grind uniformly micron-sized powder with an average particle size of 3.5-4.0μm.

[0061] Then, the jet mill powder is dehydrogenated and mechanically mixed through a dehydrogenation vessel, and the vacuum is reduced to below 0.1Pa. The dehydrog...

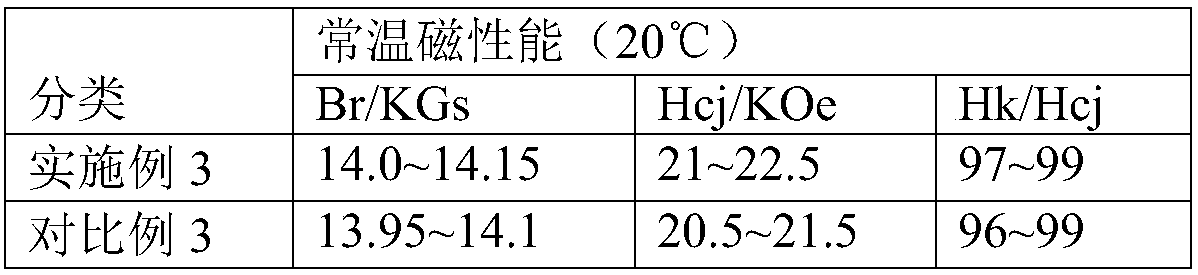

Embodiment 3

[0082] The verification with 50SH sintered NdFeB material, the raw material composition is shown in Table 11 below:

[0083] element

PrNd

Tb

Al

B

Cu

Co

Zr

Ga

Fe

wt%

28

2

0.1

0.91

0.12

1

0.17

0.2

67.5

[0084] First, according to the above formula, prepare 600Kg of raw materials, in which iron rods are derusted, the rare earth materials are treated with oil-free, moisture-free and rust-free treatment, and the prepared raw materials are melted under the condition of medium frequency induction heating by vacuum melting (SC) , And finally obtain a sheet-shaped fast-quenched NdFeB alloy with columnar crystal structure.

[0085] Then, hydrogen is absorbed in a hydrogen crusher and crushed into millimeter-sized coarse particles. The medium crusher further crushes the particles, and then grinds uniform micron-sized powder with high-pressure nitrogen through a jet mill. The average particle size of the powder is 3.5-3.8 μm.

[0086] Then the jet mill powder is dehydrogenated and mechanically m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com