Porous cobalt sulfide and nitrogen-doped carbon composite material and preparation method and application thereof

A composite material, nitrogen-doped carbon technology, applied in nanotechnology, electrochemical generators, electrical components, etc. for materials and surface science, can solve the problem of polluted environment, complex preparation process, and unsatisfactory performance of electrode materials and other problems, to achieve the effect of simple preparation method, simple reaction conditions and large yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

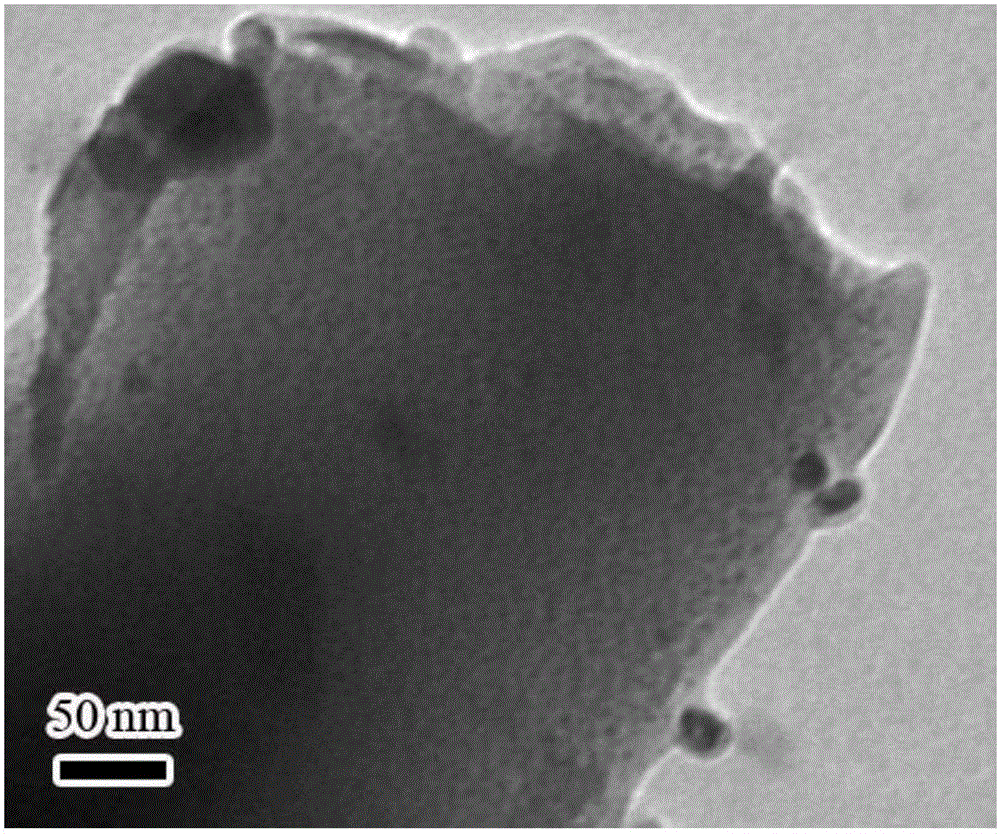

[0030] Weigh 2mmol cobalt chloride hexahydrate, 2mmol o-phenylenediamine, 4mmol o-vanillin and 5mmol elemental sulfur, grind them in an agate mortar at room temperature, then mix and grind them evenly. The mixture was transferred into a ceramic boat, which was then pushed into a tube furnace under N 2 Atmosphere, at 2°C min -1 Increase the heating rate to 40 °C and maintain at this temperature for 3 hr. Then at 5°C min -1 The heating rate was increased to 600 °C and maintained at this temperature for 4 hours. After cooling down to room temperature with the furnace, a porous nitrogen-doped carbon composite material uniformly embedded with cobalt sulfide nanoparticles (porous cobalt sulfide and nitrogen-doped carbon composite material) is obtained.

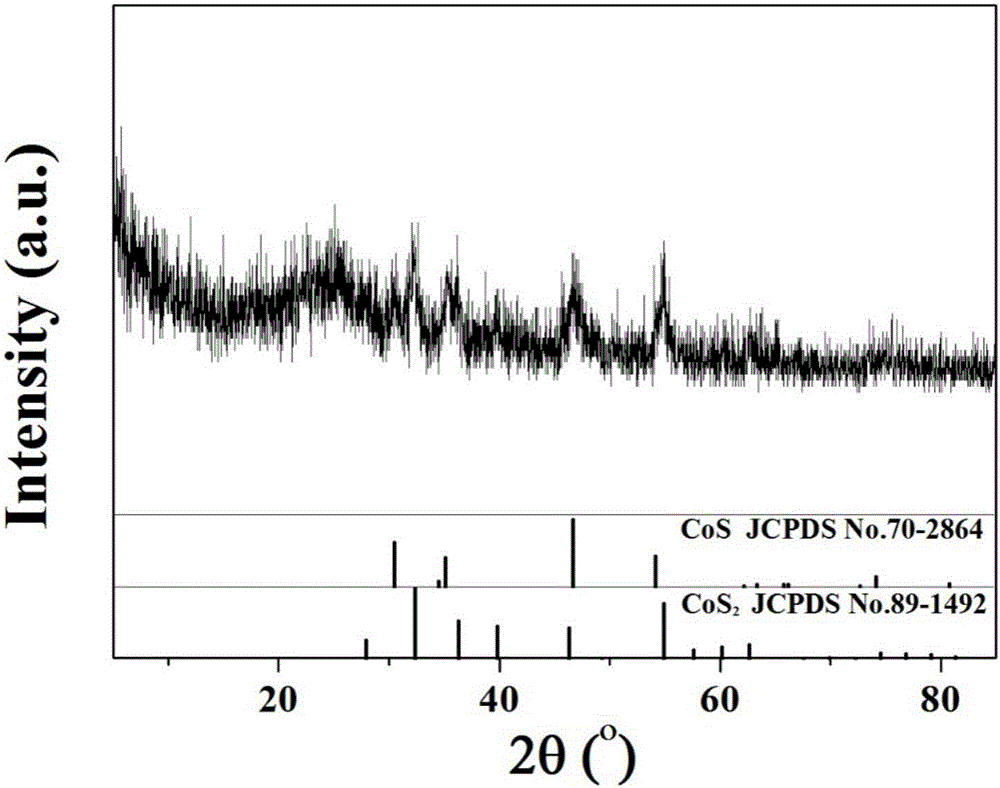

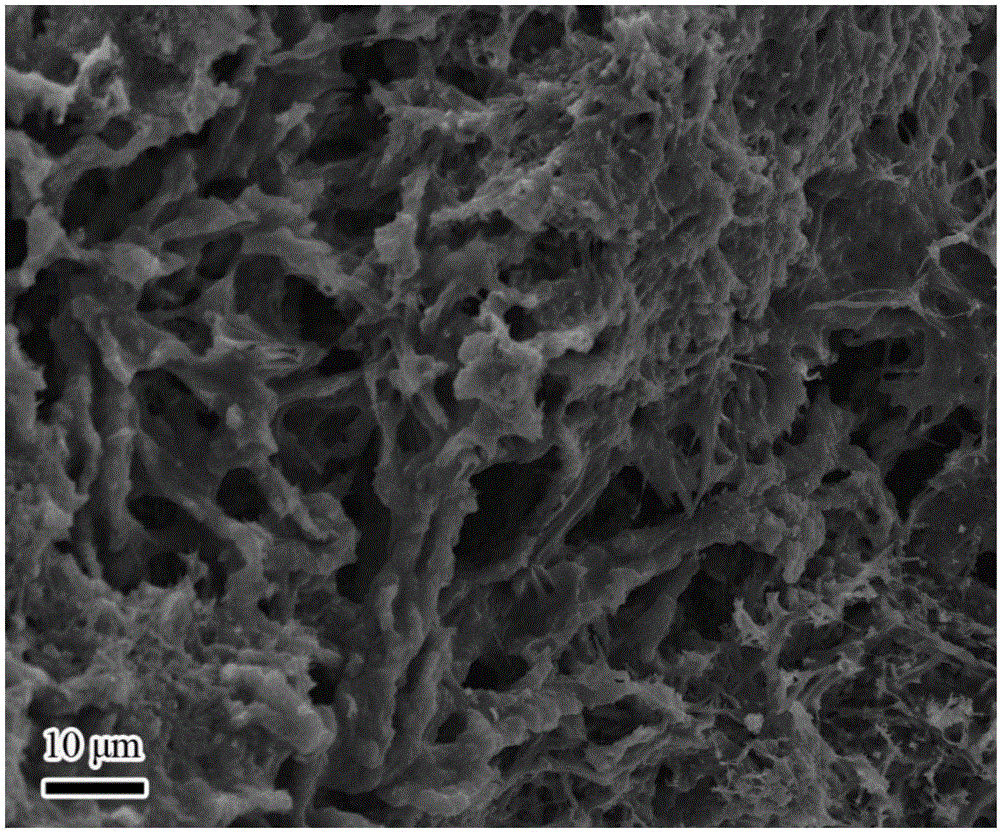

[0031] figure 1 It is the X-ray diffraction spectrum of the composite material of cobalt sulfide and nitrogen-doped carbon synthesized in this example. The results show that the composites of cobalt sulfide and nitrogen-doped c...

Embodiment 2

[0038] Weigh 2mmol cobalt chloride hexahydrate, 2mmol o-phenylenediamine, 4mmol o-vanillin and 30mmol elemental sulfur, grind them in an agate mortar at room temperature, then mix and grind them evenly. The mixture was transferred into a ceramic boat, which was then pushed into a tube furnace under N 2 Atmosphere, at 2°C min -1 Increase the heating rate to 40 °C and maintain at this temperature for 3 hr. Then at 5°C min -1 The heating rate was increased to 600 °C and maintained at this temperature for 4 hours. After cooling down to room temperature with the furnace, the porous cobalt sulfide and nitrogen-doped carbon composite material is obtained.

[0039] Similar to Example 1, related characterization and testing were carried out on the prepared composite material of cobalt sulfide and nitrogen-doped carbon, and the results were similar to Example 1.

Embodiment 3

[0041] Weigh 2mmol cobalt chloride hexahydrate, 2mmol o-phenylenediamine, 4mmol o-vanillin and 5mmol elemental sulfur, grind them in an agate mortar at room temperature, then mix and grind them evenly. The mixture was transferred into a ceramic boat, which was then pushed into a tube furnace under N 2 Atmosphere, at 2°C min -1 Increase the heating rate to 60 °C and maintain at this temperature for 3 h. Then at 5°C min -1 The heating rate was increased to 600 °C and maintained at this temperature for 4 hours. After cooling down to room temperature with the furnace, the porous cobalt sulfide and nitrogen-doped carbon composite material is obtained.

[0042] Similar to Example 1, related characterization and testing were carried out on the prepared composite material of cobalt sulfide and nitrogen-doped carbon, and the results were similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com