Preparation method of CuCl/Cu2O/Cu porous nanosheets and obtained product

A technology of nanosheets and products, which is applied in nanotechnology, metal processing equipment, transportation and packaging, etc. It can solve the problems that the research on three-phase composite sheet structure has not been reported, and achieve easy control of the reaction process, novel reaction system and excellent morphology. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1.1 Add 0.852 g of copper chloride dihydrate (CuCl 2 ∙2H 2 O), 0.425 g of NaHCO 3 1.316 g of EDTA-2Na was added to a mixed solvent of 12.5 mL glycerol and 12.5 mL ethanol, and stirred to obtain a transparent solution;

[0028] 1.2 Transfer the above solution to the reactor and react at 200 °C for 16 h;

[0029] 1.3 After the product is centrifuged and washed, CuCl / Cu 2 O / Cu porous nanosheets.

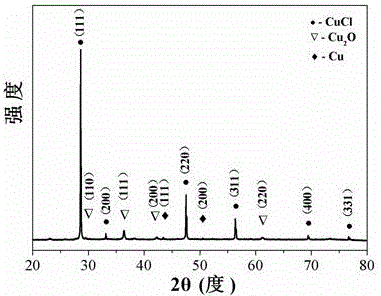

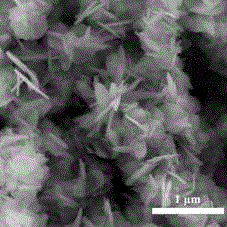

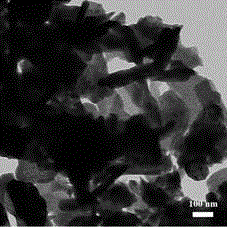

[0030] The phase structure and microscopic morphology of the product are as follows: Figure 1-3 shown. figure 1It is the XRD pattern of the product. It can be found that all the X-ray diffraction peaks are consistent with the JCPDS card (06-0344, 05-0667, 04-0836), corresponding to CuCl, Cu 2 O and Cu crystal phases, proving that CuCl, Cu 2 O and Cu, as CuCl / Cu 2 O / Cu three-phase composite structure; figure 2 with 3 They are the SEM and TEM photos of the product respectively. It can be found that the microscopic morphology of the product shown in the SEM and TEM image...

Embodiment 2

[0032] 2.1 Add 0.560 g of CuCl 2 ∙2H 2 O, 0.168 g of NaHCO 3 , 0.623 g of EDTA-2Na was added to a mixed solvent of 15.0 mL glycerol and 10.0 mL ethanol, and stirred to obtain a transparent solution;

[0033] 2.2 Transfer the above solution to the reactor and react at 190 °C for 2 h;

[0034] 2.3 After the product is centrifuged and washed, CuCl / Cu 2 O / Cu porous nanosheets. The size of the nanosheets is 0.08-0.13 μm, the thickness is 7-11 nm, and the pore size is 1.1-2.3 nm.

Embodiment 3

[0036] 3.1 Add 1.868 g of CuCl 2 ∙2H 2 O, 1.273 g of NaHCO 3 , 3.625 g of EDTA-2Na was added to a mixed solvent of 10.4 mL glycerol and 20.6 mL ethanol, and stirred to obtain a transparent solution;

[0037] 3.2 Transfer the above solution to the reactor and react at 220 °C for 23 h;

[0038] 3.3 After the product is centrifuged and washed, CuCl / Cu 2 O / Cu porous nanosheets. The size of the nanosheets is 1.8-2.2 μm, the thickness is 88-94 nm, and the pore size is 12.0-18.0 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com