Directly Heated Millimeter-Wave Signal Detector Based on Silicon-Based Micromachined Cantilever T-junction

A technology of signal detectors and cantilever beams, applied in the field of micro-electro-mechanical systems, can solve the problems of large circuit size and achieve low cost, high reliability, simple principle and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

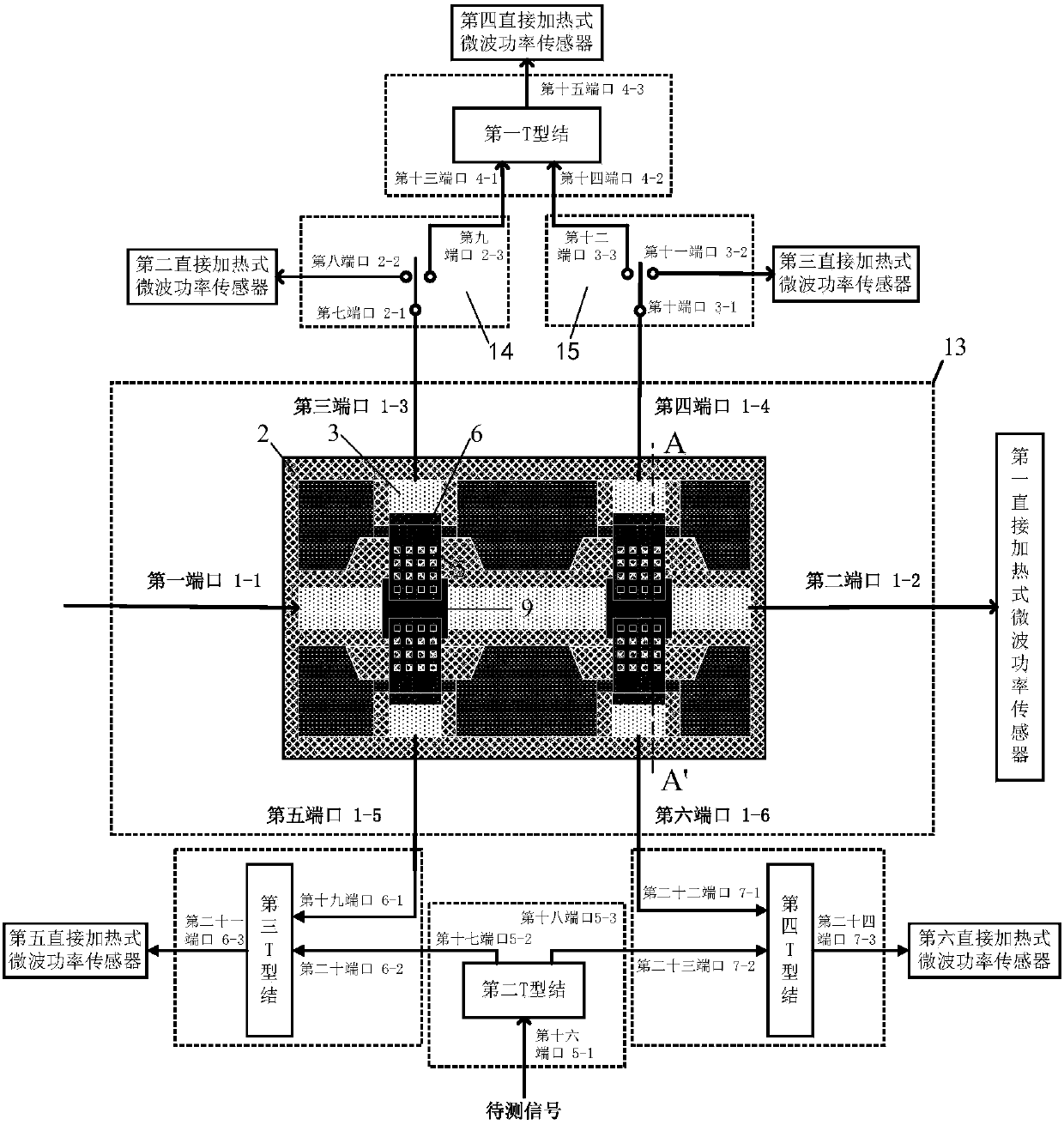

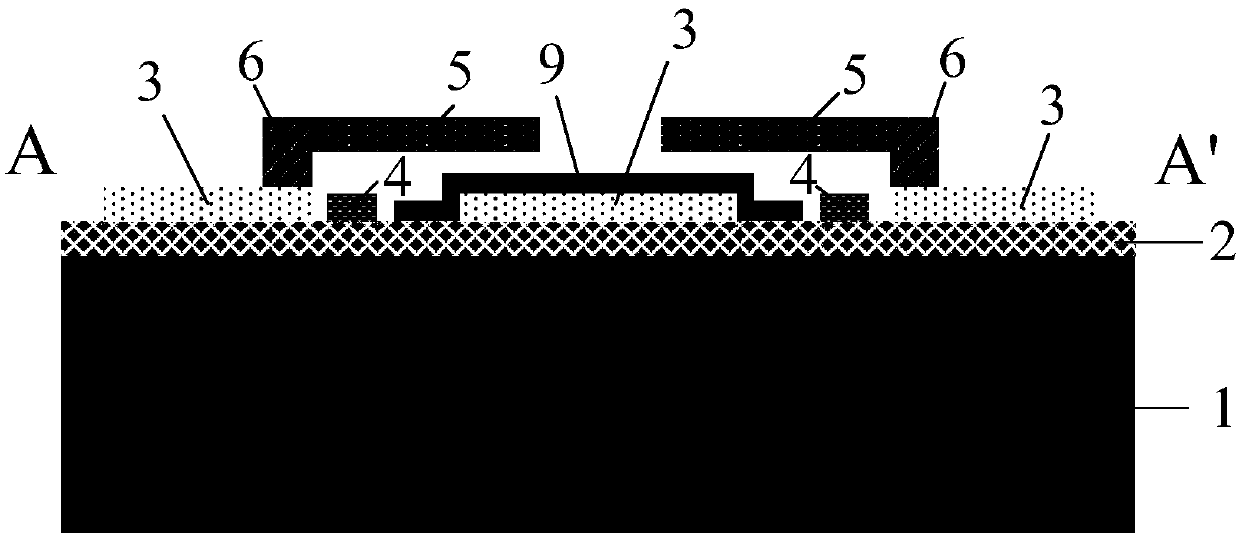

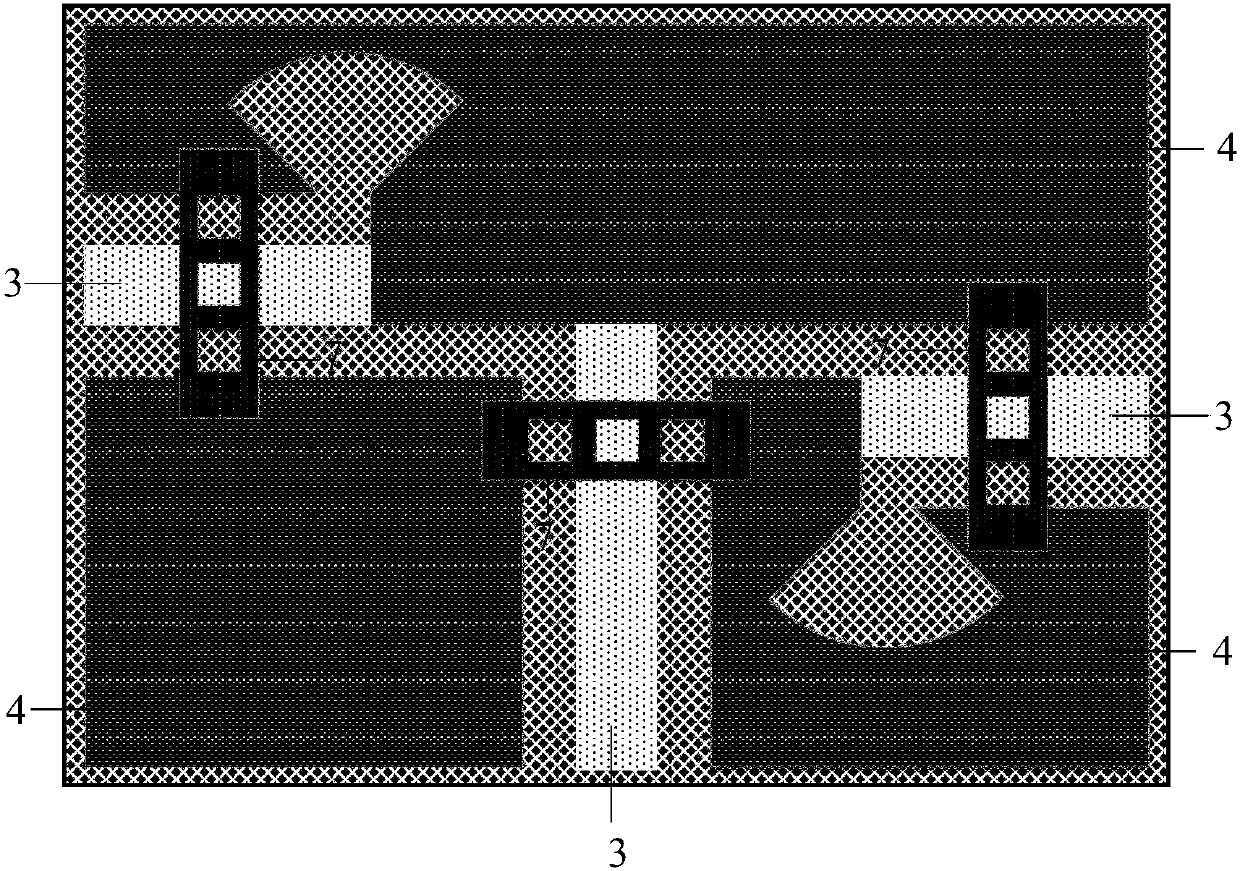

[0024] see Figure 1-7 , the present invention proposes a directly heated millimeter-wave signal detector based on a silicon-based micromechanical cantilever T-junction. It mainly includes: cantilever beam coupling structure 13, T-junction, direct heating microwave power sensor and switch. Among them, the cantilever beam coupling structure 13 is used to couple part of the power of the signal to be measured for frequency and phase detection; the T-junction is a three-port device, which can be used for power distribution and power synthesis without isolation resistors; direct heating microwave power sensor It is used to detect the power of the microwave signal, the principle is based on the Joule effect and the Seebeck effect; the switch is used to switch between two states of coupling power detection and frequency detection.

[0025] The ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com