A kind of preparation method of graphene oxide/manganese dioxide composite material

A technology of manganese dioxide and composite materials, applied in the field of wave-absorbing materials, can solve problems such as polluting the environment, difficult to realize large-scale production and application, and poisoning human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] 1, a kind of preparation method of graphene oxide / manganese dioxide composite material, comprises the following steps:

[0048] A) react after graphite, intercalation agent, oxidizing agent and water are mixed, obtain incompletely oxidized graphene solution;

[0049] B) After the incompletely oxidized graphite solution obtained in the above steps and the manganese source are mixed and reacted again, the graphene oxide / manganese dioxide composite material is obtained.

[0050] In the present invention, graphite, intercalation agent, oxidizing agent and water are mixed and then reacted to obtain incompletely oxidized graphene solution.

[0051] The present invention does not have special limitation to described graphite, gets final product with the graphite that is well known to those skilled in the art and is used for preparing graphene, and those skilled in the art can select and adjust according to actual production situation, product requirement and quality requiremen...

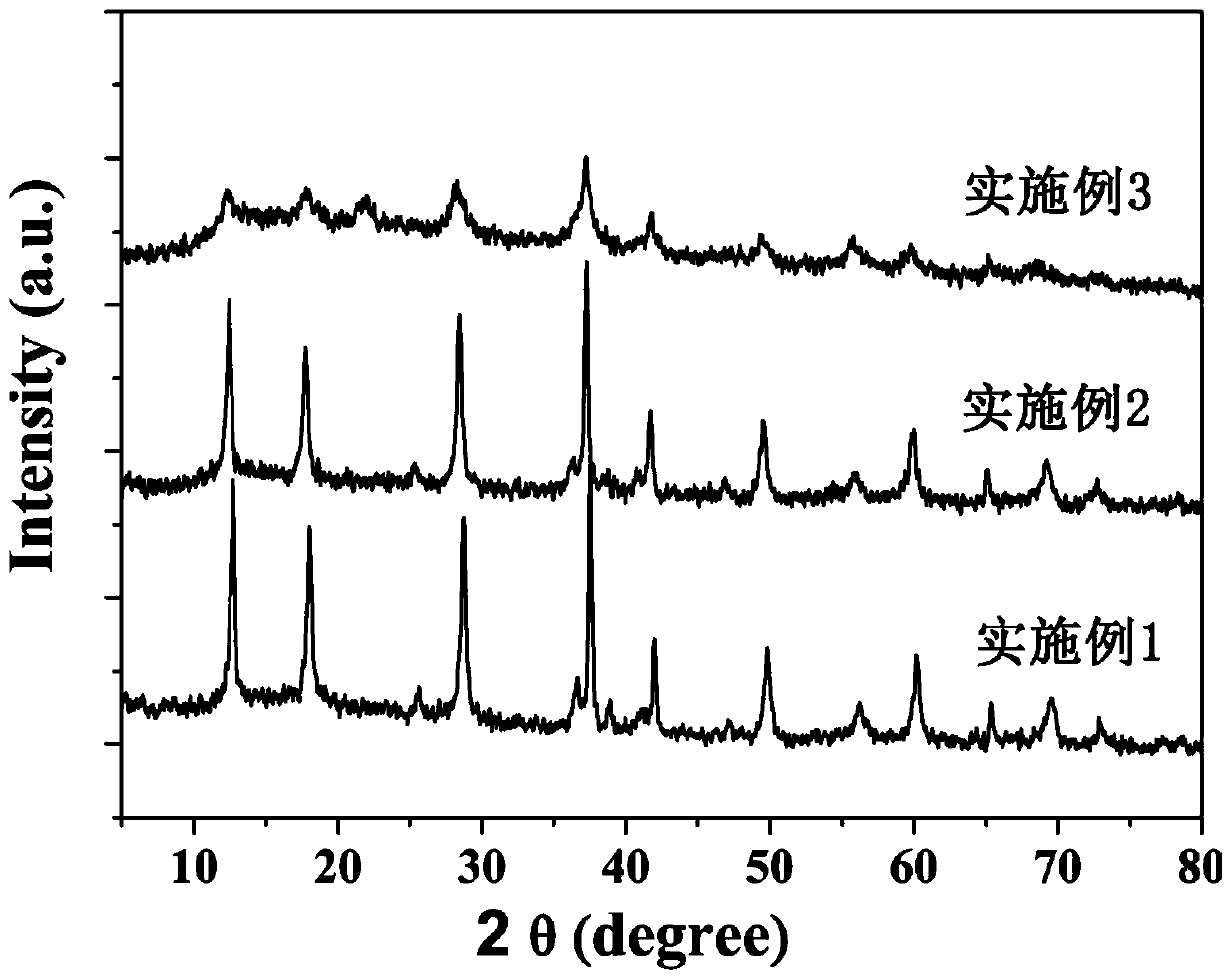

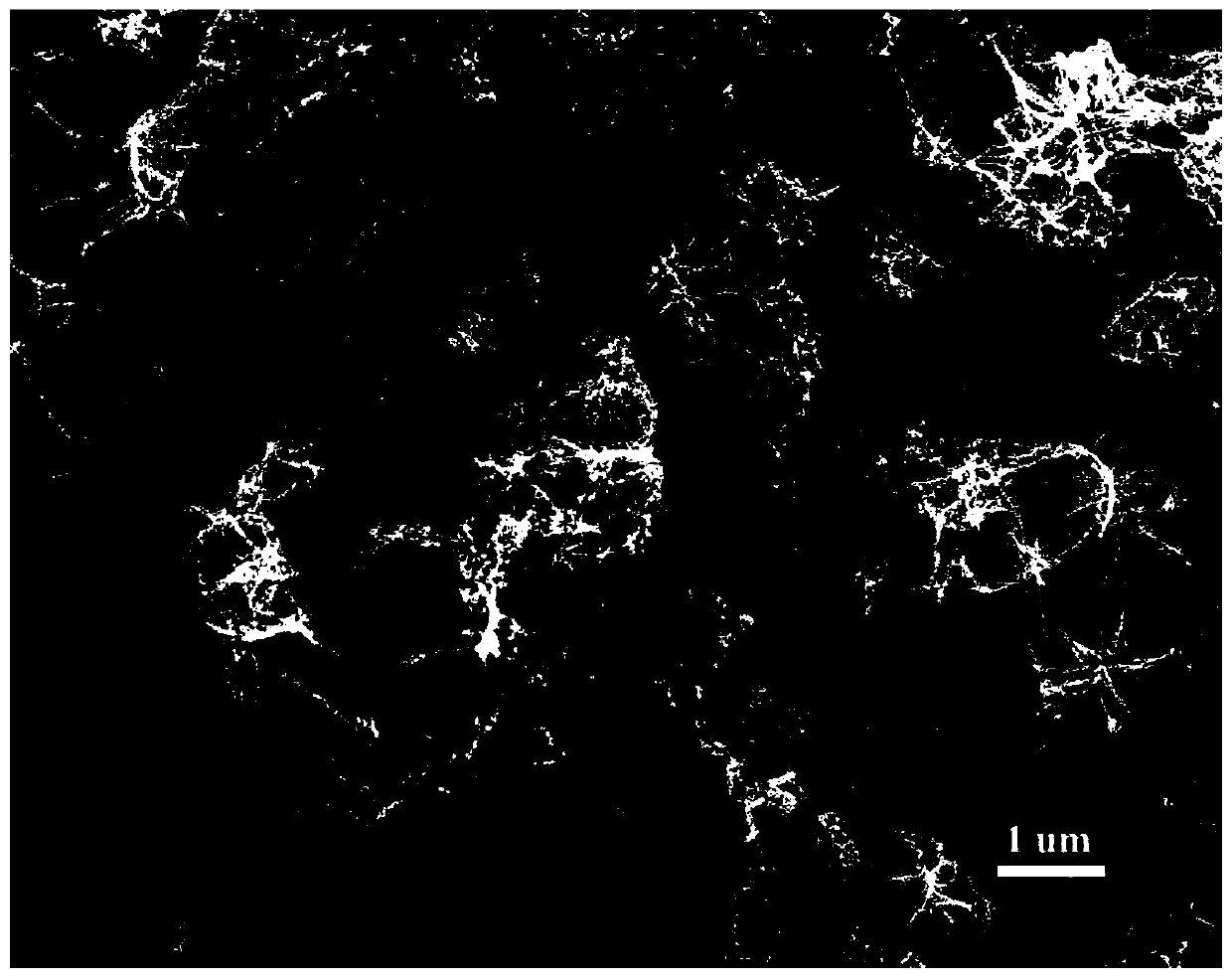

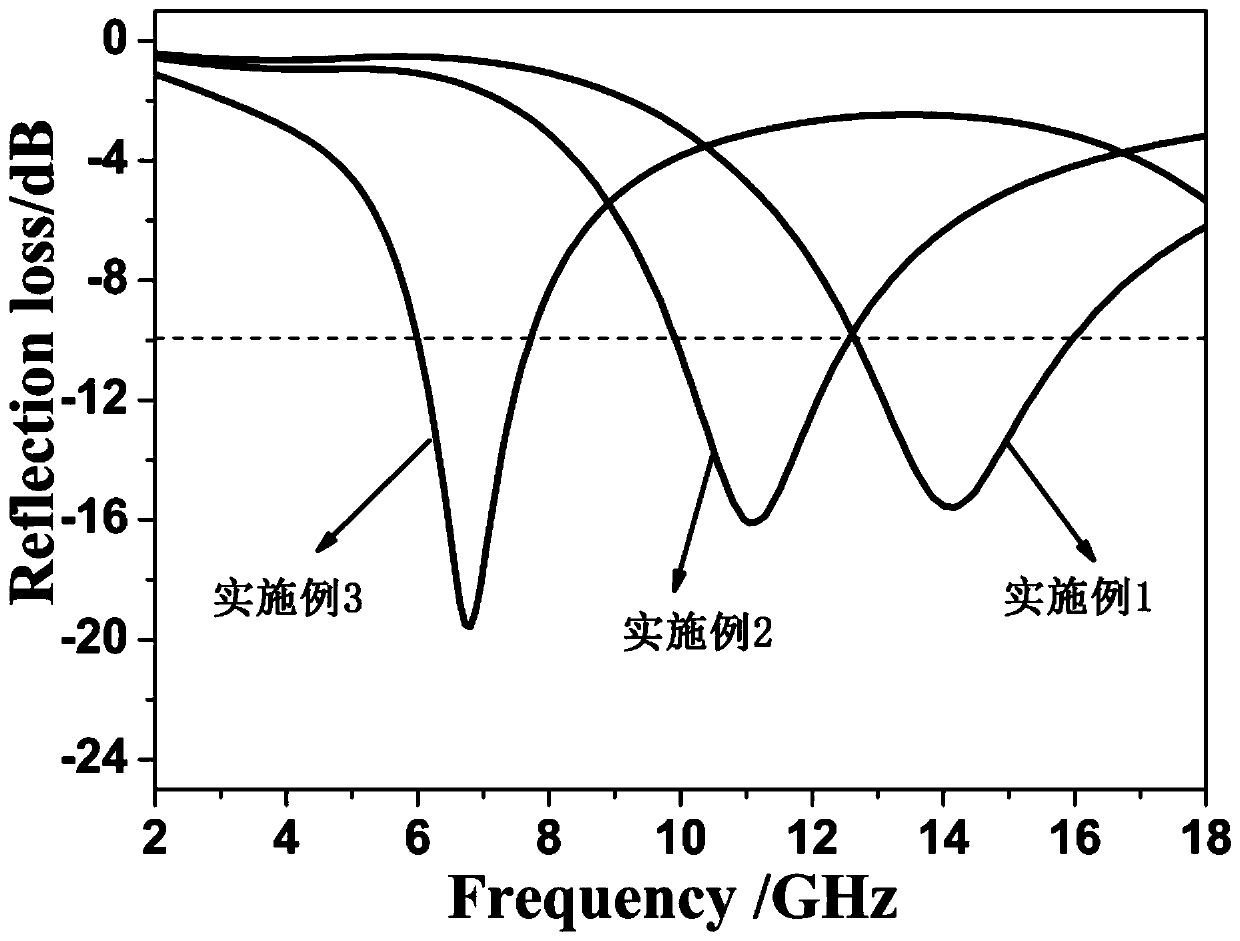

Embodiment 1

[0080] In this example, the graphene oxide-loaded manganese dioxide composite absorbing material is prepared through the following steps:

[0081] 1. Add 40 g of flake graphite to the reaction vessel, then add concentrated sulfuric acid under the condition of cooling and stirring in an ice bath, then add 30 mL of concentrated nitric acid to the solution, and continue stirring for 2 hours to obtain a graphite oxide reaction solution;

[0082] Two, slowly add 100g of potassium permanganate to the graphite oxide reaction solution obtained in step one, remove the ice bath, ensure that the system temperature is lower than 20°C, and stir for 2h to obtain the graphite oxide reaction solution;

[0083] 3. Slowly add 3.5L ultrapure water to the graphite oxide reaction solution obtained in step 2, control the temperature not to exceed 35° C., stir for 96 hours to make it uniformly dispersed, and after stirring and stripping for 4 days, obtain an incompletely oxidized graphene solution; ...

Embodiment 2

[0092] In this example, the graphene oxide-loaded manganese dioxide composite absorbing material is prepared through the following steps:

[0093] 1. Add 40 g of flake graphite to the reaction vessel, then add concentrated sulfuric acid under the condition of cooling and stirring in an ice bath, then add 30 mL of concentrated nitric acid to the solution, and continue stirring for 2 hours to obtain a graphite oxide reaction solution;

[0094] Two, slowly add 100g of potassium permanganate to the graphite oxide reaction solution obtained in step one, remove the ice bath, ensure that the system temperature is lower than 20°C, and stir for 2h to obtain the graphite oxide reaction solution;

[0095] 3. Slowly add 3.5L of ultrapure water to the graphite oxide reaction solution obtained in step 2, control the temperature not to exceed 35° C., stir for 96 hours to make it uniformly dispersed, and after stirring and stripping for 5 days, obtain an incompletely oxidized graphene solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com