A kind of polymer composite material mixed with kudzu root fiber powder and preparation method thereof

A kudzu root fiber and composite material technology, which is applied in the field of polymer composite material preparation, can solve the problems of environmental pollution and waste of natural resources, and achieve the effects of wide sources, high performance, and improved strength and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the preparation method of the polymer composite material that is mixed with kudzu root fiber powder, comprises the steps,

[0034](1) Preparation of kudzu root fiber powder: add water to the kudzu root dregs and stir until it is completely submerged, then use ultrasonic cleaning for 10 minutes, filter, add water to wash again, repeat the above process three times, and then put the washed kudzu root dregs at 40°C Dry for 6 hours; wrap the treated pueraria slag with filter paper, and extract it in petroleum ether solution. The temperature of the water bath during extraction is 75°C; repeat the extraction several times under the above extraction conditions until the liquid in the extractor changes from yellow-green to yellow-green. Nearly colorless, take out the kudzu root slag, and dry it for 6 hours at a temperature of 40°C to obtain the kudzu root fiber powder;

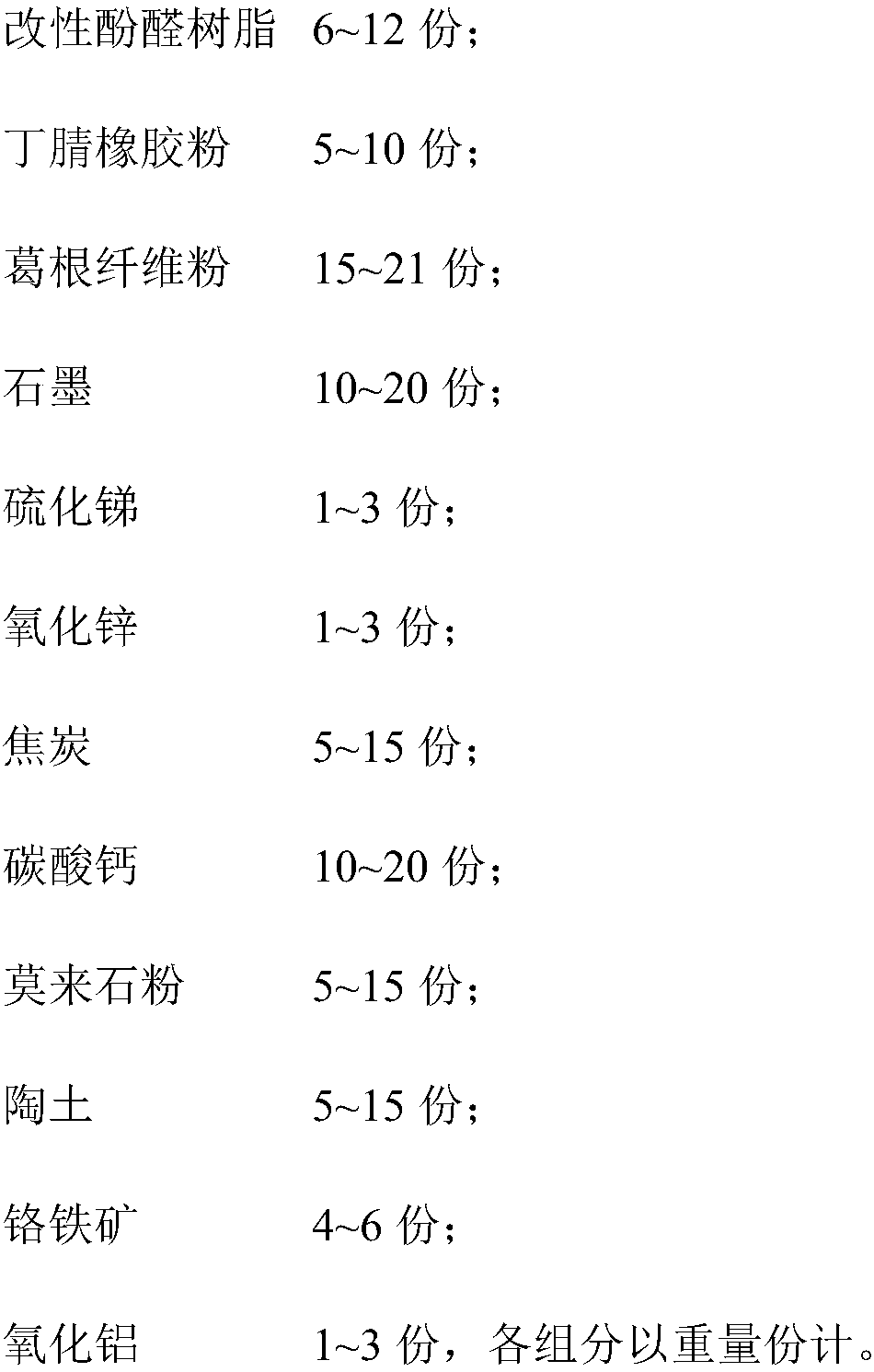

[0035] (2) Mixing: Mix the following components:

[0036] The material time is 20 minutes, ...

Embodiment 2

[0040] Embodiment 2: the preparation method of the polymer composite material that is mixed with kudzu root fiber powder, comprises the steps,

[0041] (1) Preparation of kudzu root fiber powder: add water to kudzu root dregs and stir until it is completely submerged, then use ultrasonic cleaning for 15 minutes, filter, add water to wash again, repeat the above process three times, and then put the washed kudzu root dregs at 50°C Dry for 8 hours; wrap the treated pueraria slag with filter paper, and extract it in petroleum ether solution. The temperature of the water bath during extraction is 80°C; repeat the extraction several times under the above extraction conditions until the liquid in the extractor changes from yellow-green to yellow-green. Nearly colorless, take out the kudzu root slag, and dry it at a temperature of 50°C for 8 hours to obtain the kudzu root fiber powder;

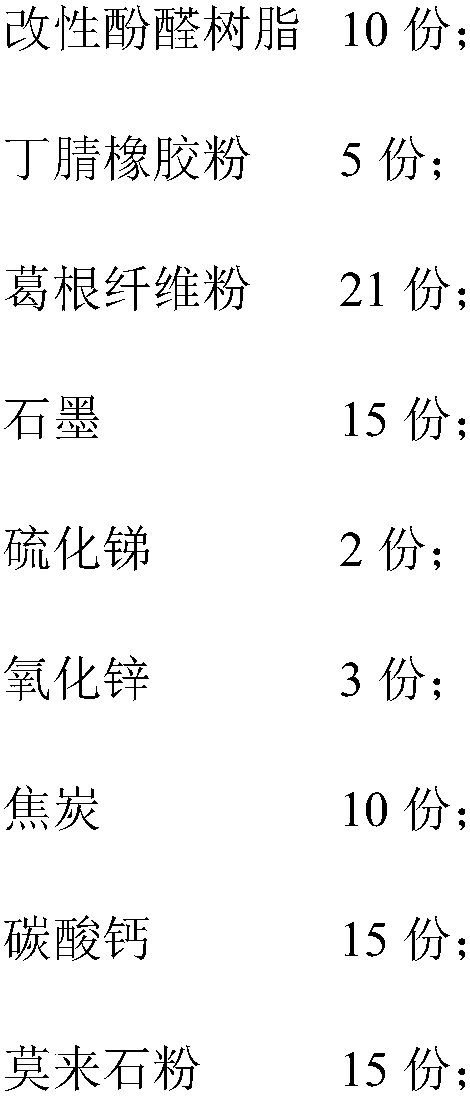

[0042] (2) Mixing: Mix the following components:

[0043]

[0044] The material time is 40 ...

Embodiment 3

[0048] Embodiment 3: the preparation method of the polymer composite material that is mixed with kudzu root fiber powder, comprises the steps,

[0049] (1) Preparation of kudzu root fiber powder: add water to kudzu root dregs and stir until it is completely submerged, then use ultrasonic cleaning for 20 minutes, filter, add water to wash again, repeat the above process three times, and then put the washed kudzu root dregs at 60°C Dry for 10 hours; wrap the treated kudzu root residue with filter paper, and extract in petroleum ether solution. The temperature of the water bath during extraction is 85°C; repeat the extraction several times under the above extraction conditions until the liquid in the extractor changes from yellow-green to yellow-green. Nearly colorless, take out the kudzu root slag, and dry it for 10 hours at a temperature of 60°C to obtain the kudzu root fiber powder;

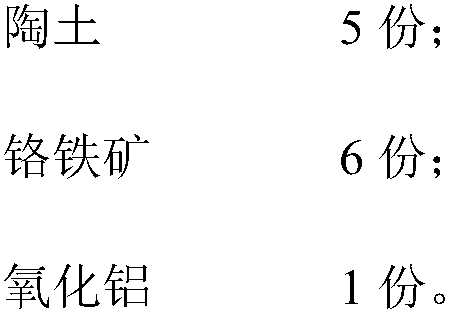

[0050] (2) Mixing: Mix the following components:

[0051]

[0052]

[0053] The materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com