Environmentally-friendly ocean antifouling paint based on self-polishing polymer/butenolide and derivatives thereof

A butenolide and marine antifouling technology, which is applied in antifouling/underwater coatings, rosin coatings, paints containing biocides, etc., can solve the problems of short antifouling period and inability to be applied, and achieve antifouling Effect of dirty time improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

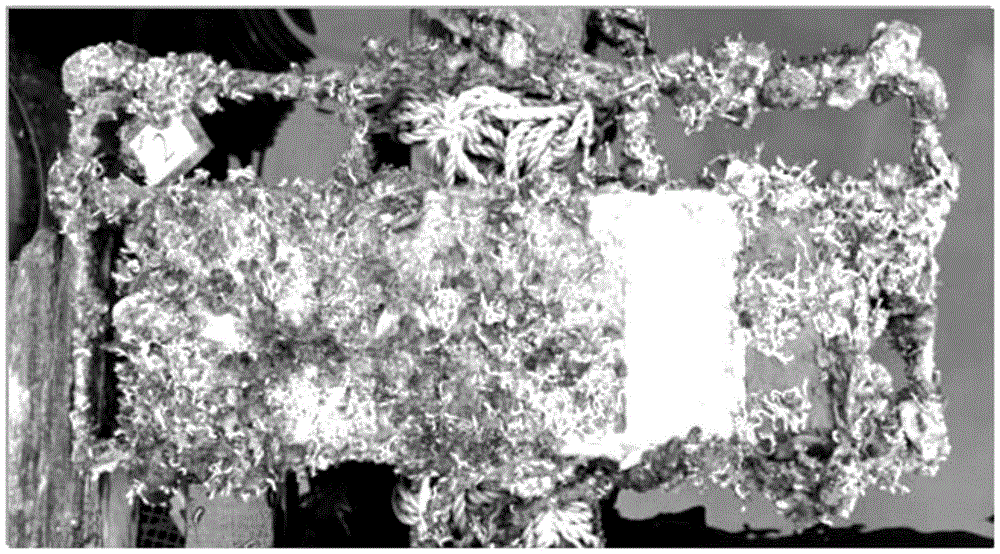

[0037] Stir and mix 95g of zinc acrylate polymer, 5g of butenolide and 20g of xylene to make an antifouling coating. According to GB / T5370-2007 "Test Method for Shallow Sea Immersion of Antifouling Paint Samples", it was conducted in Hong Kong from February 2015 to October 2015. The shallow sea hanging plate experiment was carried out in the sea area, and the results are as follows figure 1 shown. The photo of the hanging board in the picture shows that the sample has no growth of marine organisms for 8 months, indicating that the antifouling coating prepared based on the antifouling agent has good antifouling. The photo of the hanging board in the picture shows that the sample has no growth of marine life for 8 months.

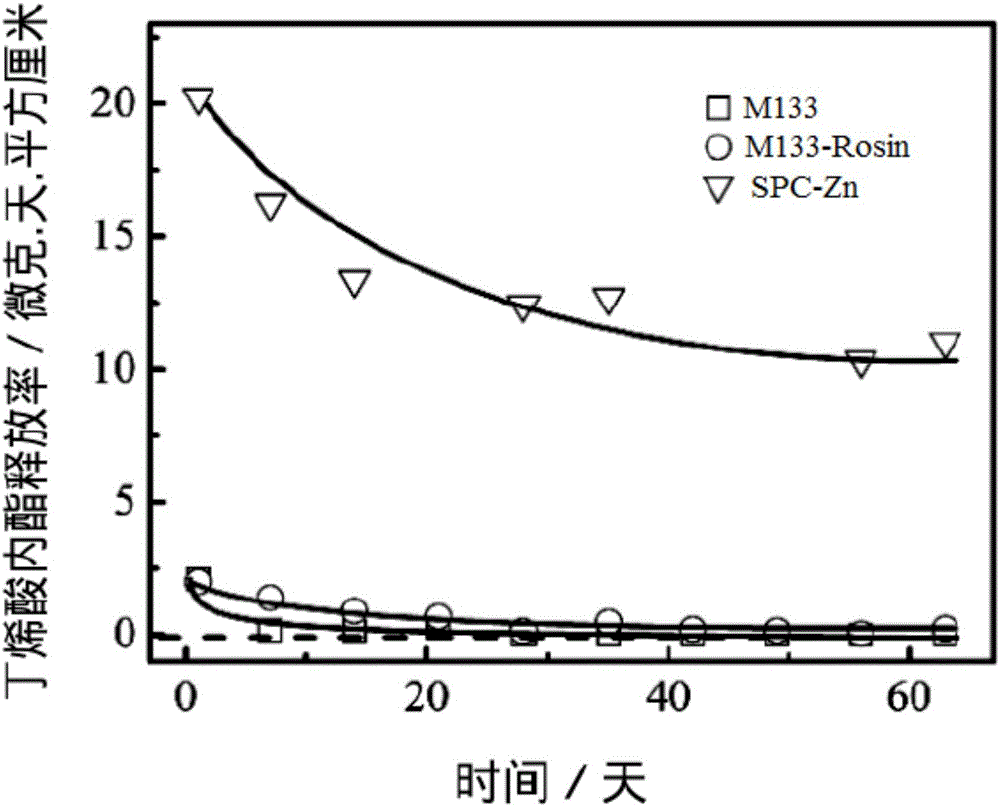

[0038] The zinc acrylate self-polishing polymer of the present invention has a good butenolide release rate. figure 2 For the comparison of the release rate curves, for non-reactive polymers such as methyl methacrylate, butenolide is basically no longer rel...

Embodiment 2

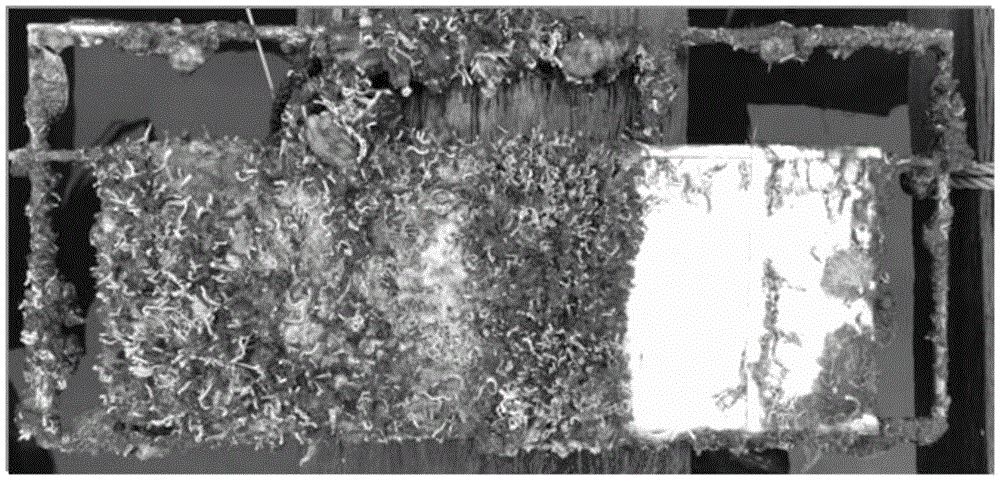

[0040] Stir and mix 35g zinc acrylate polymer, 10g butenolide, 10g zinc oxide, 2g iron oxide red and 20g xylene to make an antifouling coating, and form a film on the epoxy resin board by brushing. During the period from 2015.2 to 2015.10, the shallow sea hanging plate experiment was carried out in Hong Kong waters, and the results are as follows image 3 shown. The picture of the hanging board in the picture shows that the sample has no marine growth for 8 months.

Embodiment 3

[0042] Stir and mix 15g of silyl acrylate polymer, 5g of butenolide, 20g of cuprous oxide, 8g of zinc oxide, 2g of iron oxide red and 20g of methyl ethyl ketone to make an antifouling coating. The film was formed on the board, and the shallow sea hanging board experiment was carried out in Hong Kong waters from 2015.2 to 2015.10. The results are as follows Figure 4 shown. The picture of the hanging board in the picture shows that the sample has no marine growth for 8 months.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com