A new strain of natural yellow pigment producing bacteria xj2 and its preparation and application

A yellow pigment, XJ2 technology, applied in the field of microbial engineering, can solve the problem that the type and quantity of strains cannot meet the needs of natural yellow pigment research and development, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

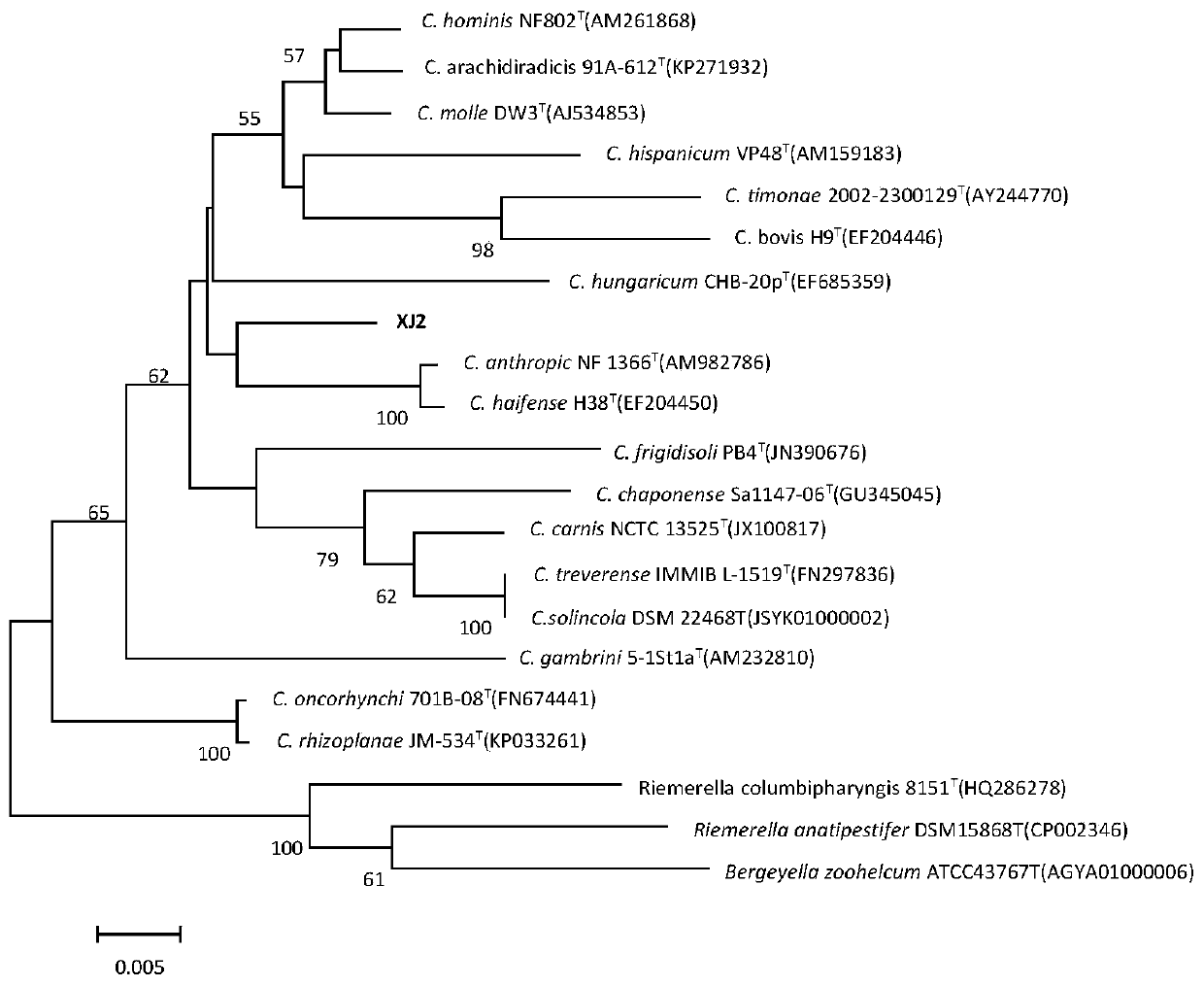

[0030]Example 1: Screening, classification and identification of Chryseobacterium sp. XJ2 CGMCC No.13157

[0031] Chryseobacterium sp. XJ2 CGMCC No. 13157 used in the present invention is isolated from Chickpea root nodules in Mulei, Xinjiang. Rinse the soil on the surface of the chickpea root with tap water, rinse the root nodules with sterile water for more than 5 times, soak the root nodules with 95% ethanol for 30 seconds, continue to rinse with sterile water for more than 5 times, and soak them in 0.1% mercuric chloride solution for 5 times. After 10 minutes, rinse the root nodules with sterile water for more than 5 times, and keep the sterile water from the last rinse and spread it on the relevant plate to detect whether the root nodules are thoroughly disinfected. Then use a scalpel to peel off the root nodules from the chickpea roots, grind the sterilized nodules with a sterile mortar, and after appropriate dilution, use the tip of a gun to draw 0.1mL of the diluted so...

Embodiment 2

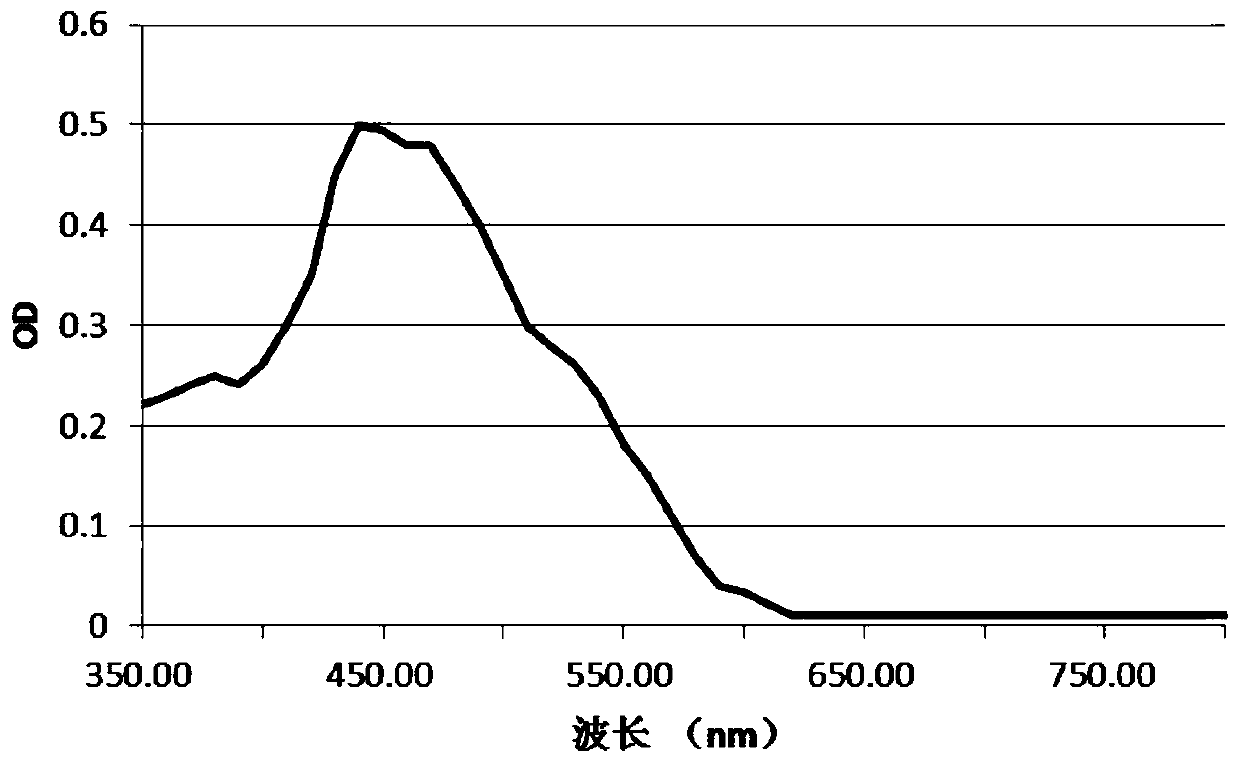

[0038] Embodiment 2: Chryseobacterium sp. (Chryseobacterium sp.) XJ2 CGMCC No.13157 Fermentation produces and extracts the method and light-absorbing characteristic of yellow pigment

[0039] In the present invention, Chryseobacterium sp. (Chryseobacterium sp.) XJ2 CGMCC No.13157 is inoculated in the fermentation medium (500mL Erlenmeyer flask filling 100mL fermentation medium, fermentation medium peptone 10g, yeast extract 5g, glucose 1g, KH 2 PO 4 3 g, pH7.0), 30 ° C, 200 rpm shaker culture for 3 days. The bacterial liquid was centrifuged at 8000rpm for 3min to obtain the bacterial cells. After the bacterial cells were washed with normal saline three times, 20mL of 95% ethanol solution was added, 50°C, 100rpm for oscillating extraction for 1h; then centrifuged at 8000rpm for 5min, the obtained supernatant The liquid is the crude yellow pigment extract; the crude yellow pigment extract is placed at a constant temperature of 60°C for vacuum concentration until it becomes dry ...

Embodiment 3

[0041] Example 3: Determination of Solubility of Yellow Pigment Produced by Chryseobacterium sp. XJ2 CGMCC No.13157

[0042] Chryseobacterium sp. (Chryseobacterium sp.) XJ2 CGMCC No.13157 was fermented and the crude extract of yellow pigment was obtained, and 10 mL of purified water, 50% ethanol, 95% ethanol, 99.8% ethanol, 50% methanol solution, Put 100% methanol, ethyl acetate, acetone, and n-butanol in colorimetric tubes, and add absolute excess yellow pigment crude extracts in various solvents. After sealing, shake and dissolve in a shaker at room temperature at 100 rpm for 12 hours to prepare saturated yellow pigment. Pigment solution. Then centrifuge at 8000rpm for 5min, take the supernatant to measure the absorbance at a wavelength of 438nm, compare it with the OD of 95% ethanol saturated yellow pigment solution, and calculate the dissolution rate, see Table 2.

[0043] Table 2: Effect of different solutions on extraction

[0044]

[0045] As shown in Table 2, it c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com