Barrel drinking water barrel lid seal detection equipment

A sealing detection, drinking water technology, applied in liquid tightness measurement using liquid/vacuum degree, detecting the appearance of fluid at the leak point, antifouling/underwater coating, etc., can solve the tedious detection process efficiency, low cleaning It can achieve the effects of good antibacterial performance, improved cleanliness, and strong adhesion and adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

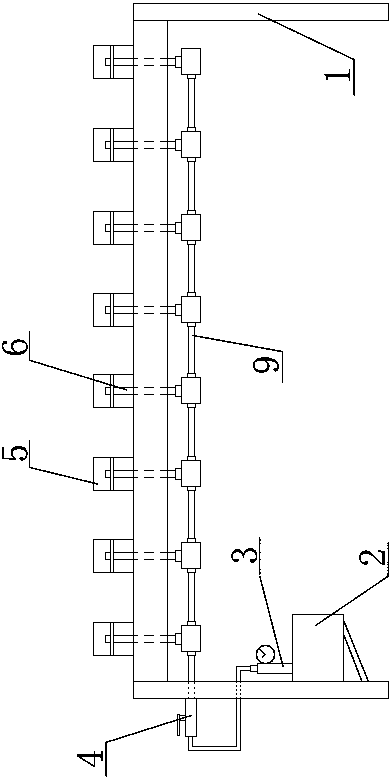

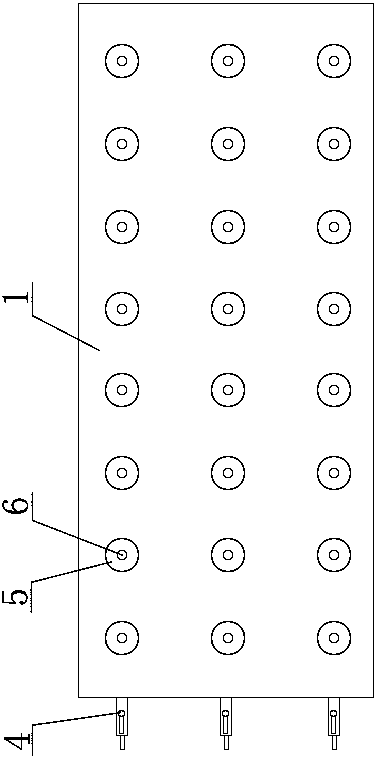

[0025] refer to Figure 1 to Figure 5 , the present invention includes a support frame 1; the support frame 1 is evenly provided with a number of lid clamping seats 5; the barrel cover clamping seats 5 are respectively provided with outlet pipes 6, and the outlet pipes 6 are respectively passed through pipelines 9 It communicates with the valve 4 on one side of the support frame 1; the valve 4 communicates with the air pump 2 provided with a pressure gauge 3 through a pipeline;

[0026] The thickness of the nano antibacterial coating is 100um, and the nano antibacterial coating is obtained by spraying the nano antibacterial coating; the nano antibacterial coating is prepared according to the following process:

[0027] Mix nano-silver powder, nano-zinc oxide and nano-silica gel powder evenly according to the weight ratio of 3:2:1 to obtain a nano-composite material;

[0028] Mix quartz sand, diatomaceous earth and dolomite at a mass ratio of 2:1:1, then calcinate at 800°C for...

Embodiment 2

[0033] A nano antibacterial coating, which is prepared according to the following process:

[0034] Mix nano-silver powder, nano-zinc oxide and nano-silica gel powder evenly according to the weight ratio of 3:2:1 to obtain a nano-composite material;

[0035] Mix quartz sand, diatomaceous earth and dolomite at a mass ratio of 2:1:1, then calcinate at 800°C for 30 minutes, take it out, cool to room temperature, then mix nanocomposites at a mass ratio of 10:1, and let stand for 30 minutes , then add 1M sulfuric acid of the same quality, soak for 15min, filter, and dry to obtain component A;

[0036] Add sodium carboxymethylcellulose, isopropanol, ethanol, polydimethylsiloxane, vinyltrimethoxy Base silane, butyl acetate, acrylic resin and deionized water, stirred at 1000rpm for 5min to obtain component B;

[0037] Add component A to component B, stir at 1500rpm for 10min, stop stirring, raise the temperature to 60°C, keep warm for 30min, cool down to room temperature naturally, ...

Embodiment 3

[0039] The antibacterial test of the coating of the embodiment of the present invention 2: test material is divided into two groups, is respectively control group and test group, and size is 40 * 40 * 5mm, and control group does not do any processing, and test group sprays coating of the present invention, coating The thickness is 100um. All the test materials were placed in a petri dish, the bacterial solution was dropped on a sterile plate, incubated in an incubator for 120min, then taken out, and counted under a microscope. The bactericidal ability of the coating is judged by the number of colonies. The lower the number of colonies, the stronger the bactericidal ability. Take Escherichia coli and Staphylococcus aureus as examples, see Table 1 for details:

[0040] Table 1

[0041] group

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com