A kind of preparation method of shredded stem for thin cigarette

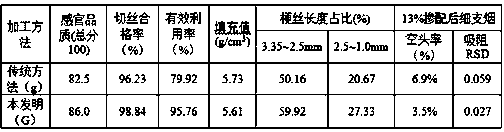

A technology of thin cigarettes and cut stems, which is applied in the fields of tobacco, application, and treatment of tobacco, and can solve problems such as filling value, low silk yield, inability to effectively guarantee the quality stability of cut stems, and poor swelling effect of stem slices, etc., to achieve Improve the effective operation rate of production, improve the sensory quality of cut stems, and improve the uniformity of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

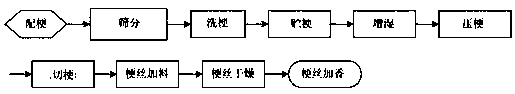

[0047] like figure 1 As shown, preparing shredded stems for fine cigarettes comprises the following steps:

[0048] (1) Blending stems: according to the requirements, the tobacco stems from different parts, different origins, and different varieties are blended in proportion to obtain the blending stem materials, and the blending stem materials are divided into two blocks, A and B;

[0049] (2) Sieving: Sieve the two blocks A and B obtained in step (1), and select tobacco stems with a length of 30-75mm;

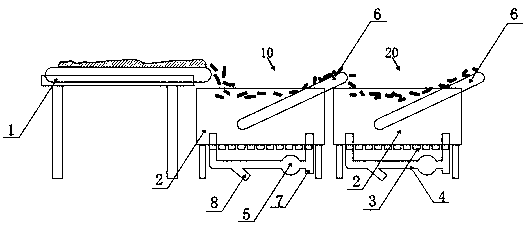

[0050] (3) Stem washing: Wash the two blocks A and B that have been processed in step (2), and the washing is carried out in a stem washing machine with a temperature gradient; Rinse in a water bath with a water temperature of 45°C; then soak in a solution containing 25% ethanol and 0.5% KOH at 65°C, adjust the flow rate of the material so that the time for passing through the soaking liquid is about 20s; finally enter T=50°C, pH= 5.0 and rinse in a solution containing 0.5%...

Embodiment 2

[0063] like figure 1 As shown, preparing shredded stems for fine cigarettes comprises the following steps:

[0064] (1) Blending stems: according to the requirements, the tobacco stems from different parts, different origins, and different varieties are blended in proportion to obtain the blending stem materials, and the blending stem materials are divided into two blocks, A and B;

[0065] (2) Sieving: Sieve the two blocks A and B obtained in step (1), and select tobacco stems with a length of 30-75mm;

[0066] (3) Stem washing: wash the two blocks A and B that have been processed in step (2), and the washing is carried out in a stem washing machine with a temperature gradient; Rinse in a water bath at 40°C; then soak in a 65°C solution containing 15% ethanol and 0.4% KOH, adjust the material flow rate so that the time for passing through the soaking solution is about 15s; finally enter T=45°C, pH=4.5 and Rinse in a solution containing 0.6% pectinase, 1.3% cellulase, 0.8% p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com