Preparation method and application of mesoporous alumina supported palladium-based catalyst

A technology of mesoporous alumina and catalyst, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problem of inability to form stable alumina tetrahedral structural units, poor thermal stability of mesoporous alumina materials, and toxic aluminum alkoxides Cost and other issues, to achieve good processing capacity, reduce product raw material costs, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) weigh 10g of pseudo-boehmite (industrial grade, water loss rate of 15%), and dissolve it in 150mL of deionized water to obtain solution A;

[0021] (2) After stirring the solution A for 30min, dilute nitric acid was added to it to adjust the pH of the solution to 3 to obtain solution B;

[0022] (3) Add 5 g of polyethylene glycol to solution B, stir for 180 min, dry at a constant temperature at 100°C for 10 hours, and dry at a constant temperature at 600°C for 2 hours to obtain mesoporous alumina C;

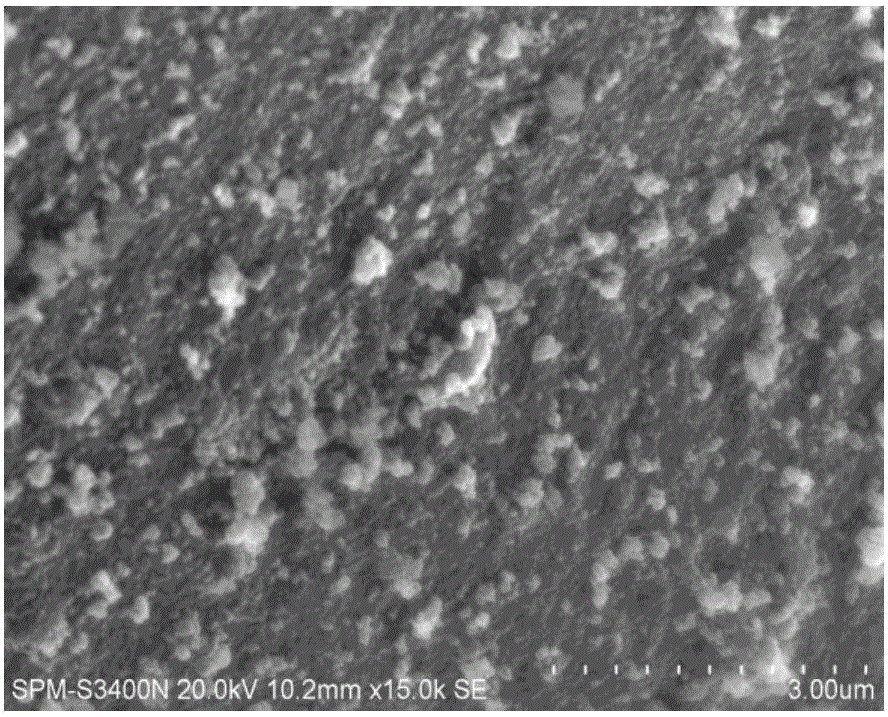

[0023] (4) Weigh 5g of mesoporous alumina C dissolved in 0.625ml of Pd(NO 3 ) 2 solution, stirred for 30 minutes, dried at a constant temperature of 100°C for 12 hours, and at a constant temperature of 400°C for 2 hours to obtain a solid powder D. The powder solid D is the catalyst, denoted as Pd / Al 2 o 3 -1. The specific surface area of this catalyst still has 240m2 measured by BET adsorption instrument. 2 / g, the pore volume is 0.42cc / g, and the pore diameter ...

Embodiment 2

[0028] (1) weigh 10g of pseudo-boehmite (industrial grade, water loss rate of 15%), and dissolve it in 150mL of deionized water to obtain solution A;

[0029] (2) After stirring the solution A for 30min, dilute nitric acid was added to it to adjust the pH of the solution to 3 to obtain solution B;

[0030] (3) Add 5 g of polyethylene glycol to solution B, stir for 180 min, dry at a constant temperature at 100°C for 10 hours, and dry at a constant temperature at 600°C for 4 hours to obtain mesoporous alumina C;

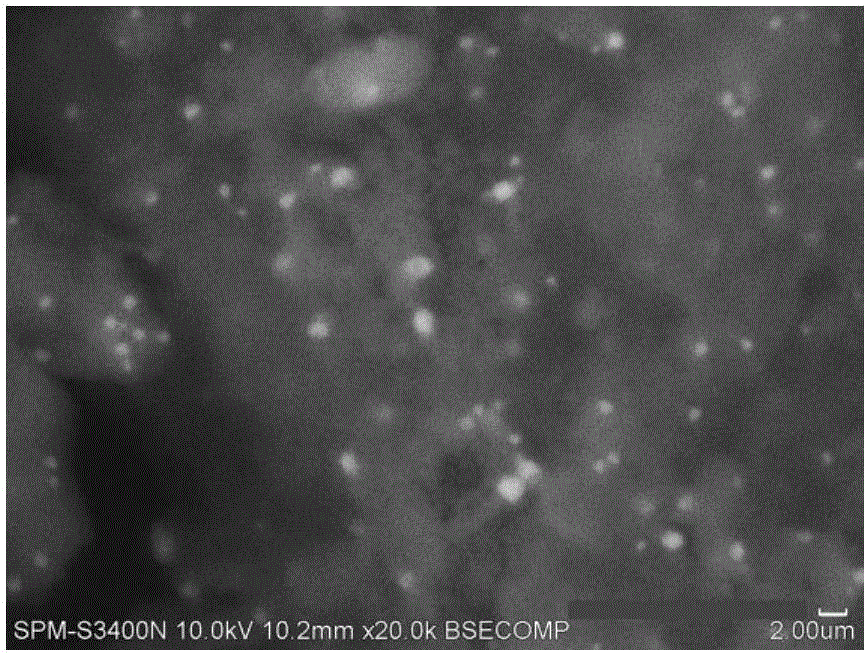

[0031] (4) Weigh 5g of mesoporous alumina C dissolved in 0.625ml of Pd(NO 3 ) 2 solution, stirred for 30 minutes, dried at a constant temperature of 100°C for 24 hours, and at a constant temperature of 600°C for 4 hours to obtain a solid powder D, which is the catalyst, denoted as Pd / Al 2 o 3-2. The specific surface area of this catalyst still has 201m2 measured by BET adsorption instrument. 2 / g, the pore volume is 0.39cc / g, and the pore diameter is 5.9nm.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com