Perovskite type photocatalyst with double modification of doping and loading, and preparation method thereof

A perovskite-type, double-modified technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve low solar energy utilization, low quantum yield, hindering applications, etc. problems, to achieve the effect of facilitating electron transfer, simple process, and promoting degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

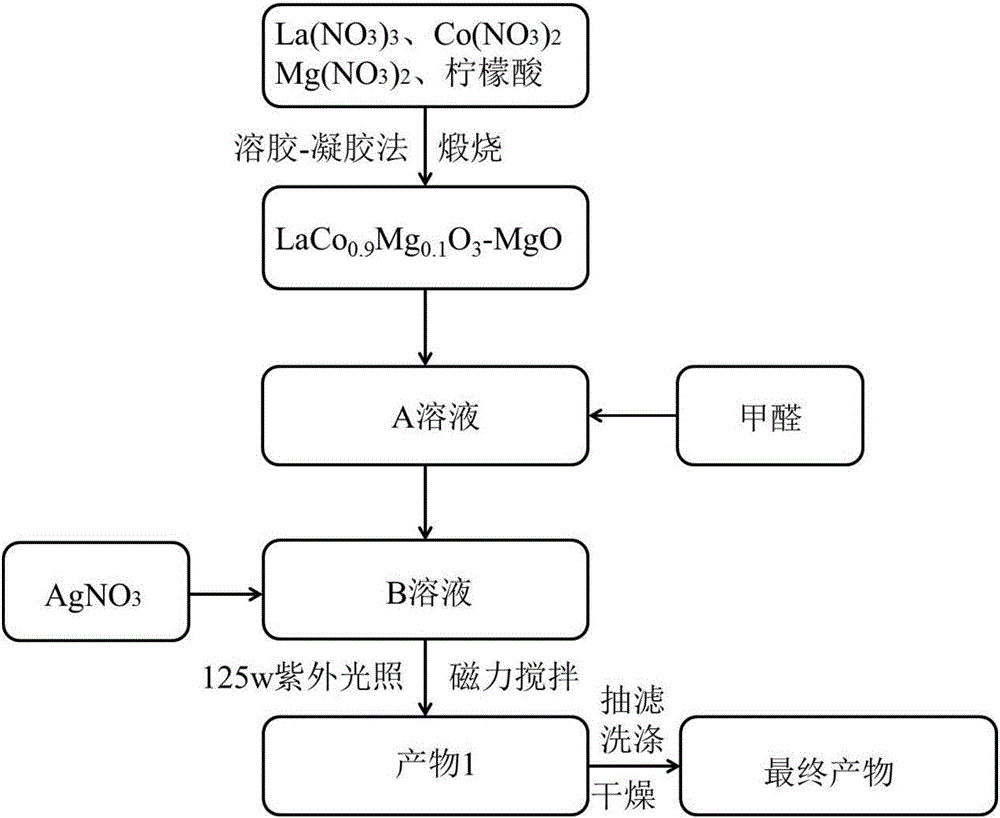

[0031] The present invention LaCo 0.9 Mg 0.1 o 3 -The preparation method of MgO-Ag perovskite type visible light catalyst, comprises the steps:

[0032] Step 1, weigh the corresponding amount of La(NO 3 ) 3 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O and Mg(NO 3 ) 2 ·6H 2 O, then weigh the corresponding amount of citric acid according to the molar ratio of metal cation and citric acid as 1:1, and the above corresponding amount of La(NO 3 ) 3 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O, Mg(NO 3 ) 2 ·6H 2O and citric acid are dissolved together in deionized water and fully dissolved to obtain a mixed solution. Add ammonia (30wt%) dropwise to the mixed solution while magnetically stirring until the pH of the mixed solution is 8, and continue to magnetically stir the mixed solution in a water bath at 80°C. The mixed solution was solified for 3 hours, and the solified mixed solution was placed at 110°C for 12 hours to become gelled, and then placed at 400°C and 750°C for 4 hours in an air atm...

Embodiment 2

[0039] The present invention LaCo 0.9 Mg 0.1 o 3 -The preparation method of MgO-Ag perovskite type visible light catalyst, comprises the steps:

[0040] Step 1, weigh the corresponding amount of La(NO 3 ) 3 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O and Mg(NO 3 ) 2 ·6H 2 O, then weigh the corresponding amount of citric acid according to the molar ratio of metal cation and citric acid as 1:1, and the above corresponding amount of La(NO 3 ) 3 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O, Mg(NO 3 ) 2 ·6H 2 O and citric acid are dissolved together in deionized water and fully dissolved to obtain a mixed solution. Add ammonia (30wt%) dropwise to the mixed solution while magnetically stirring until the pH of the mixed solution is 8, and continue to magnetically stir the mixed solution in a water bath at 80°C. 3h to fully sol the mixed solution, put the solified mixed solution at 110°C for 12h to become gelatinized, then put it at 400°C and 750°C, and roast in air atmosphere for 4h to remove or...

Embodiment 3

[0047] The present invention LaCo 0.9 Mg 0.1 o 3 -The preparation method of MgO-Ag perovskite type visible light catalyst, comprises the steps:

[0048] Step 1, weigh the corresponding amount of La(NO 3 ) 3 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O and Mg(NO 3 ) 2 ·6H 2 O, then weigh the corresponding amount of citric acid according to the molar ratio of metal cation and citric acid as 1:1, and the above corresponding amount of La(NO 3 ) 3 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O, Mg(NO 3 ) 2 ·6H 2 O and citric acid are dissolved together in deionized water and fully dissolved to obtain a mixed solution. Add ammonia (30wt%) dropwise to the mixed solution while magnetically stirring until the pH of the mixed solution is 8, and continue to magnetically stir the mixed solution in a water bath at 80°C. 3h to fully sol the mixed solution, put the solified mixed solution at 110°C for 12h to become gelatinized, then put it at 400°C and 750°C, and roast in air atmosphere for 4h to remove or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com