A kind of preparation method of modified ionic liquid catalyst for removing sulfur dioxide

A technology for modifying ions and sulfur dioxide, which is used in the preparation/purification of sulfur, catalysts for physical/chemical processes, chemical instruments and methods, etc., and can solve the problem that sulfur process methods have not been reported, have not utilized sulfur resources, and have not solved sulfur resources. To achieve the effect of promoting gas-liquid mass transfer capacity, short preparation time and strong selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 50 g of citric acid into a beaker, add 50 mL of deionized water to make a citric acid solution with a mass fraction of 50%, and stir and mix at 60 °C for 1 h. Under the condition of stirring, slowly drop 48mL MDEA (the mass ratio of MDEA to citric acid is 1:1) into the citric acid solution, and stir and mix at 60°C for 1h. Add 16.7mL of water to the beaker and continue stirring at 60°C for 8h. Add ammonia water dropwise and stir to adjust the pH of the ionic liquid to 7.5. A solution made of 5 g of hydroxylamine hydrochloride was added dropwise and stirred for 1 h for preliminary modification. Then add 5 g of sodium thiosulfate and stir for 1 h to carry out further modification to obtain a modified ionic liquid catalyst.

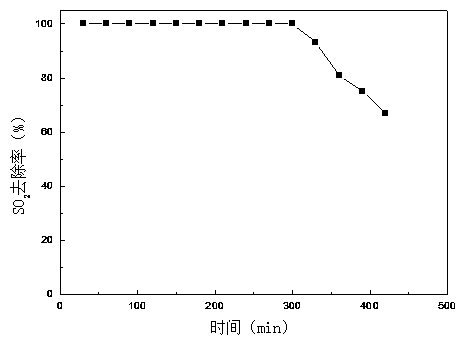

[0031] The activity test of the catalyst was carried out in a 250mL three-necked flask reactor, and the reaction conditions were: SO 2 The concentration is 1000ppm, the gas flow rate is 500mL / min, the volume of ionic liquid is 100mL, the reac...

Embodiment 2

[0033] Weigh 50 g of citric acid into a beaker, add 50 mL of deionized water to make a citric acid solution with a mass fraction of 50%, and stir and mix at 50 °C for 1 h. Under the condition of stirring, slowly drop 72mL MDEA (the mass ratio of MDEA to citric acid is 1.5:1) into the citric acid solution, and stir and mix at 50°C for 1h. Add 33.3mL of water to the beaker, and continue to stir at 50°C for 8h. Add ammonia water dropwise and stir to adjust the pH of the ionic liquid to 7.5. A solution made of 12.5 g of hydroxylamine hydrochloride was added dropwise and stirred for 1 h for preliminary modification. Then add 12.5 g of sodium thiosulfate and stir for 1 h to carry out further modification to obtain a modified ionic liquid catalyst.

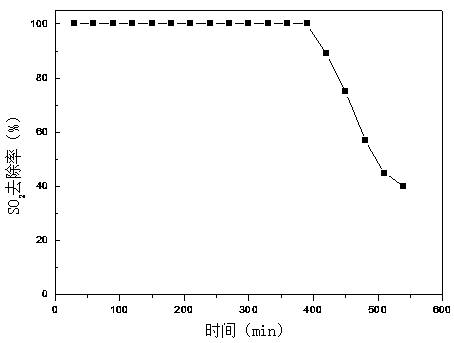

[0034] The activity test of the catalyst was carried out in a 250mL three-necked flask reactor, and the reaction conditions were: SO 2 The concentration is 1000ppm, the gas flow rate is 500mL / min, the volume of ionic liquid is 100mL, ...

Embodiment 3

[0036] Weigh 40 g of citric acid into a beaker, add 60 mL of deionized water to make a citric acid solution with a mass fraction of 40%, and stir and mix at 70 °C for 1 h. Under the condition of stirring, slowly drop 69mL MDEA (the mass ratio of MDEA to citric acid is 1.8:1) into the citric acid solution, and stir and mix at 70°C for 1h. Add 14.7mL of water to the beaker and continue stirring at 70°C for 8h. Add ammonia water dropwise and stir to adjust the pH of the ionic liquid to 7.2. A solution made of 16.8 g of ferrous sulfate was added dropwise and stirred for 1 h for preliminary modification. Then add 16.8 g of sodium thiosulfate and stir for 1 h to carry out further modification to obtain a modified ionic liquid catalyst.

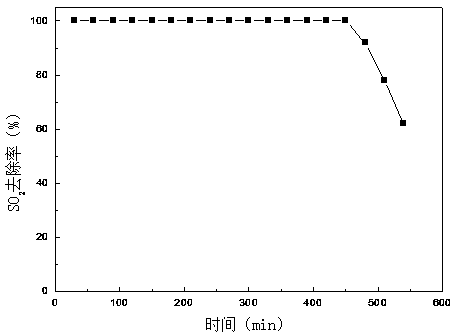

[0037] The activity test of the catalyst was carried out in a 250mL three-necked flask reactor, and the reaction conditions were: SO 2 The concentration is 1000ppm, the gas flow rate is 500mL / min, the volume of ionic liquid is 100mL, the reaction t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com