Immobilized heteropoly acid ionic liquid catalyst and preparation method thereof

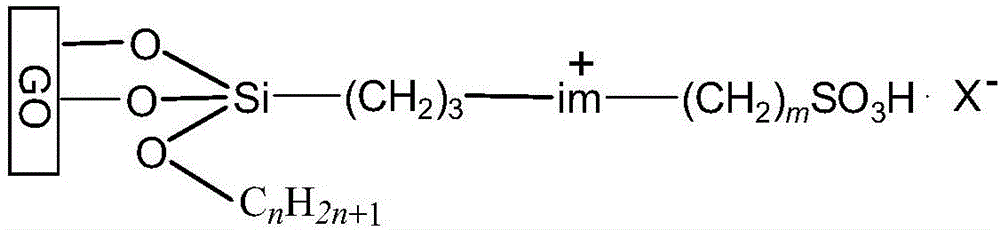

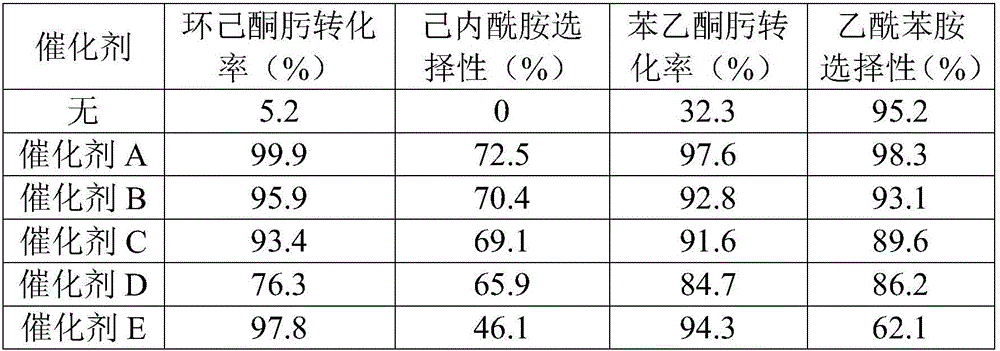

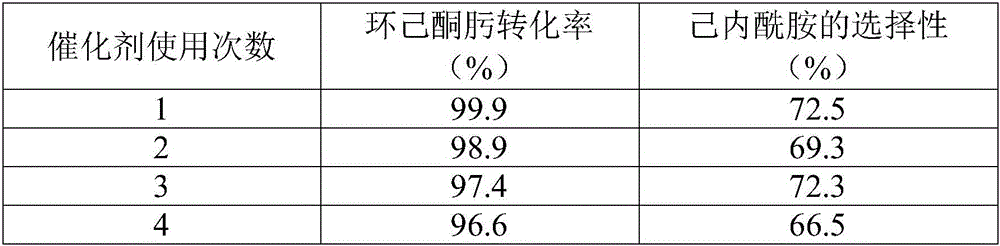

A technology of ionic liquid and catalyst, which is applied to graphene oxide immobilized heteropolyacid ionic liquid catalyst and its preparation. The application field of this catalyst in liquid-phase Beckmann reaction can solve the problem of easy loss and deactivation of catalytic active components, Unsatisfactory catalyst activity, poor support structure stability, etc., to achieve the effect of stable mechanical and chemical properties, simple and easy synthesis method, and stable catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] GO was prepared by the improved Hummers method, and the specific process was as follows: 1 g of graphite powder and 0.5 g of NaNO were added to a 250 mL four-neck flask equipped with a mechanical stirring device under ice bath conditions. 3 and 23mL concentrated sulfuric acid. While vigorously stirring, a certain amount of KMnO was slowly added in batches 4 After that, react for 1.5h. Then the temperature of the water bath was raised to 30° C., and after slowly adding 100 mL of deionized water dropwise, the stirring was continued for 1.5 h. After the stirring was completed, the temperature of the water bath was raised to 95 °C, and after stirring for 30 min, it was cooled to room temperature. Add 300mL of deionized water and 0.6mL of hydrogen peroxide dropwise, stir well and filter with suction, wash with 5% hydrochloric acid first, and then wash the sample with deionized water until neutral. Dry at 80°C for 5h to obtain graphite oxide powder. Before use, wash with ...

Embodiment 2

[0031] Add 20 times of 3-chloropropyltrimethoxysilane to the GO suspension prepared in Example 1, transfer the flask to an oil bath, stir at 110° C. for 24 h under reflux, and cool to room temperature. After filtration, repeated washing with ethanol and deionized water, and drying at 80°C, the synthesized GO with silane chains was added to the flask, and then 6.8 times of imidazole and 900 times of toluene were added, and the mixture was stirred and refluxed at 110°C for 24 hours. After the reaction, cool to room temperature. GO with imidazole was obtained after filtration, washing and drying. The synthesized GO with imidazole, propyl sultone and toluene were mixed according to the ratio of 1:12:900, and the reaction was stirred at 80°C for 24h. After the reaction, GO with imidazole group of alkylsulfonic acid was obtained by filtering, washing and drying. The synthesized GO with imidazole group of alkylsulfonic acid, phosphotungstic acid and water were mixed according to th...

Embodiment 3

[0033]Add 30 times of 3-chloropropyltriethoxysilane to the GO suspension prepared in Example 1, transfer the flask to an oil bath, stir and reflux at 90°C for 24 hours, and cool to room temperature. After filtration, washing and drying, the synthesized GO with silyl group was added into the flask, then 10 times of imidazole and 400 times of toluene were added, and the mixture was stirred and refluxed at 110°C for 24 hours. After the reaction, cool to room temperature. GO with imidazole was obtained after filtration, washing and drying. The synthesized GO with imidazole, butyl sultone and toluene were mixed according to the ratio of 1:18:400, and the reaction was stirred at 80°C for 24h. After the reaction, GO with imidazole group of alkylsulfonic acid was obtained by filtering, washing and drying. The synthesized GO with imidazole group of alkylsulfonic acid, phosphotungstic acid and water were mixed according to the ratio of 1:18:500, and stirred and reacted at 60°C for 24h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com