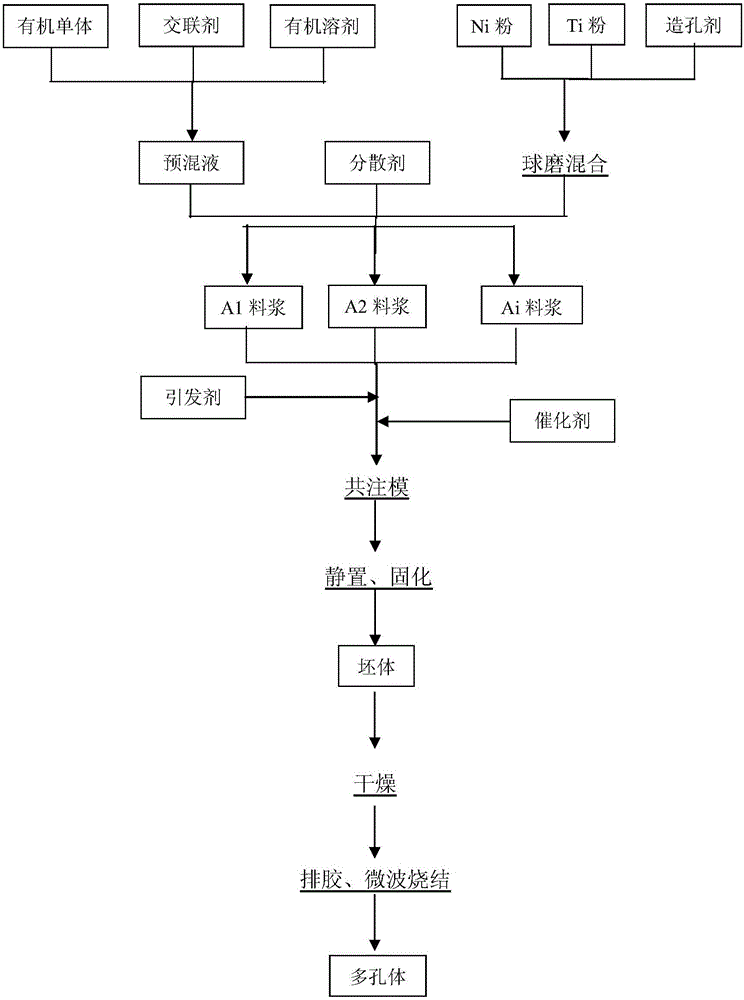

Co-gelation injection molding forming method of gradient porous metal

A gradient porous and gel injection molding technology, which is applied in the field of powder metallurgy preparation, can solve the problems of microwave technology and other problems, and achieve the effects of simple process, energy saving and fast sintering speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

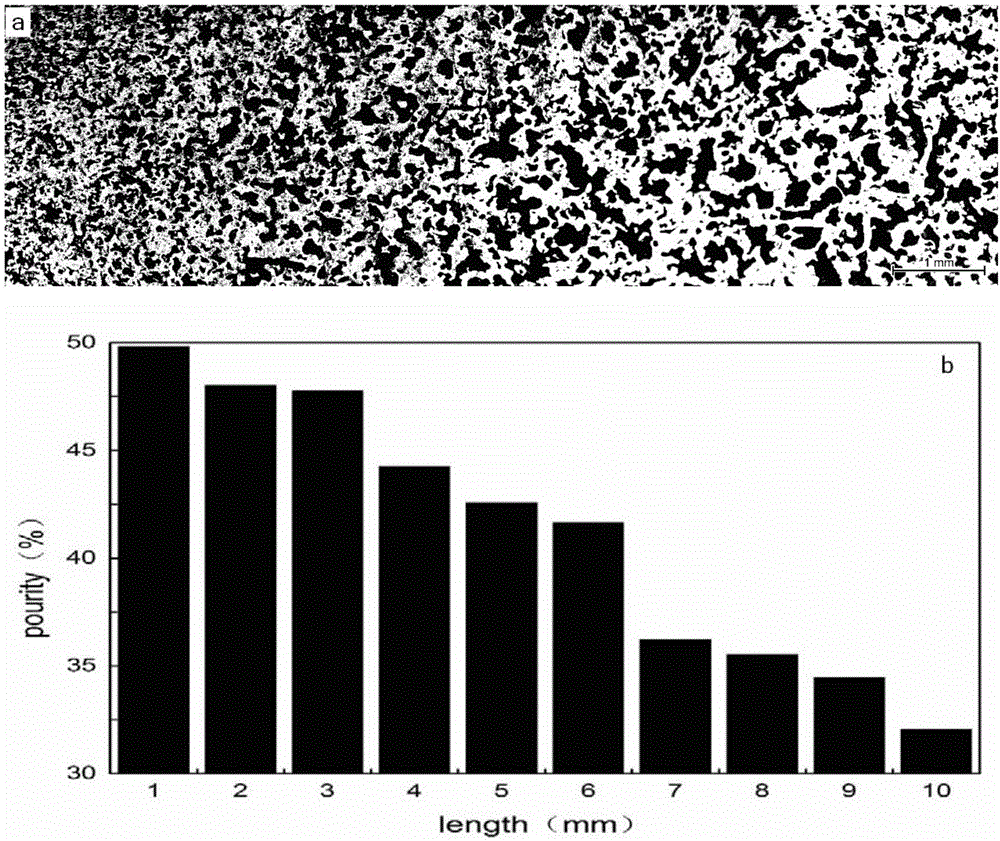

[0055] Combine -325 mesh spherical Ni powder and -325 mesh TiH 2 Mix according to the atomic ratio of 58.9:49.8, and ball mill for 2 hours to obtain mixed powder; combine the monomer 2-hydroxyethyl methacrylate (HEMA) and the crosslinking agent hexanediol diacrylate (HDDA) in mass ratio Mix at a ratio of 10:1 and dissolve it in n-octanol to obtain a premixed solution with a monomer mass fraction of 25wt%; mix the weighed and mixed powder and its mass fraction of silok7074 with a mass fraction of 1.5wt%, and mix for 10h by ball milling. Into two slurries with a solid phase volume fraction of 52vol% and 42vol%; vacuum degassing for 30 minutes, add initiator and catalyst with monomer mass of 0.5wt% to the two slurries, and stir them evenly. The material is injected into the mold at the same time according to the design, and placed in a vacuum for 20 minutes and then heated to 60°C for curing for 20 minutes; after the solidified body is demolded, it is placed in acetone for 2 hours ...

Embodiment 2

[0057] Mix -325 mesh spherical Ni powder and -325 mesh Ti powder at an atomic ratio of 58.9:49.8, and ball mill for 2 hours to obtain mixed powder; the monomer 2-hydroxyethyl methacrylate (HEMA) and crosslinking agent Hexanediol diacrylate (HDDA) is mixed in a mass ratio of 12:1, and it is dissolved in n-octanol to obtain a premixed solution with a monomer mass fraction of 30wt%; the weighed and mixed powder and its mass The fraction of 1.8wt% oleic acid was mixed, ball milled for 10 hours, and the solid phase volume fraction was 54vol% slurry A respectively; by introducing the particle size -200 mesh 8wt% urea, particle size -100 mesh 20wt% urea, With a particle size of 60 mesh and 35wt% urea, slurries B, C and D with a loading capacity of 54vol%, 52vol% and 50vol% were prepared by the above-mentioned similar process; the above-mentioned slurries were vacuum degassed for 20 minutes, and monomers were added. Initiator and catalyst with a mass of 0.5wt%, after stirring uniformly...

Embodiment 3

[0059] The monomer 2-hydroxyethyl methacrylate (HEMA) and the crosslinking agent hexanediol diacrylate (HDDA) are mixed in a mass ratio of 10:1, and the monomer mass is obtained after dissolving in n-octanol A premixed liquid with a fraction of 25% by weight; the hydrogenated-dehydrogenated titanium powder with an average particle size of 45 microns and a mass fraction of 1.5% by weight of silok7074 are mixed, and ball-milled for 10 hours to obtain a solid phase volume fraction of 52vol% and 42vol%. Two kinds of slurries; vacuum degassing for 30 minutes, add initiator and catalyst of 0.5wt% monomer mass to the two slurries respectively, after stirring uniformly, the two slurries are injected into the mold at the same time according to the design, and in vacuum After standing for 20 minutes, it is heated to 60°C and cured for 20 minutes; after curing, the body is released from the mold, placed in acetone for 2 hours to remove most of the n-octanol, and then placed in a vacuum dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com