Visible light response nano TiO2 and preparation method for self-cleaned ceramic coating film containing same

A visible light, self-cleaning technology, applied in the direction of coating, titanium oxide/hydroxide, titanium dioxide, etc., can solve the problems of different degrees of agglomeration, poor adhesion, low absorption of visible light, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

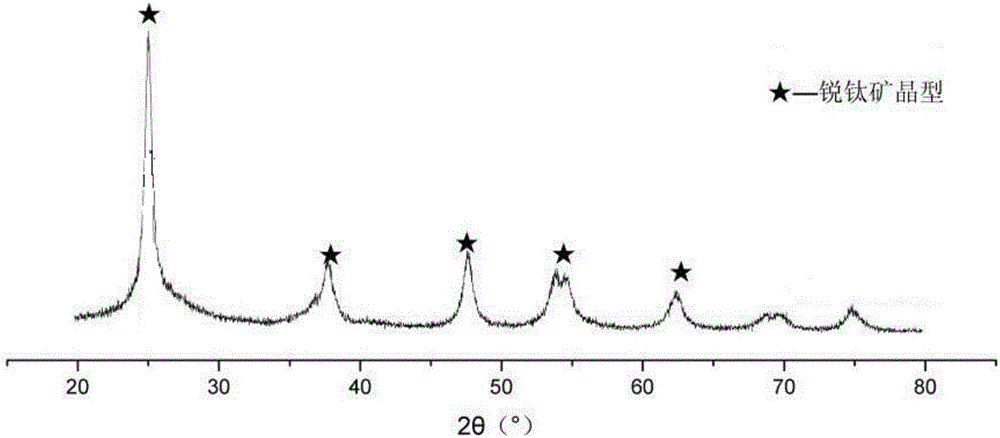

[0055] Example 1: Synthesis of silicon-doped nano-TiO with visible light response 2 particles.

[0056] Put 540mL of neutral to slightly alkaline deionized water (pH=7.0) into a 1L reaction flask equipped with a stirring device and a heating device, and mix 1mL of tetramethoxysilane and 25mL of titanic acid under the condition of stirring (speed 500rpm) A mixture of n-butyl ester (TBT) and 80 mL of ethanol (EtOH) was added to the reaction flask to generate a white precipitate. At room temperature and under continuous stirring, 5 mL of 30% hydrogen peroxide (H 2 o 2 ) was added to the suspension until at least 80% of the white precipitate was dissolved, and left to age for 22 hours to obtain a yellow transparent sol. Turn on stirring and heating, heat up to reflux (about 95°C), reflux for 8h, and use 3-4mL concentration of 25% ammonia (NH 3 ·H 2 O) As a pH regulator, adjust the pH of the system to 6.5, then cool naturally to room temperature to obtain silicon-doped nano-Ti...

Embodiment 2

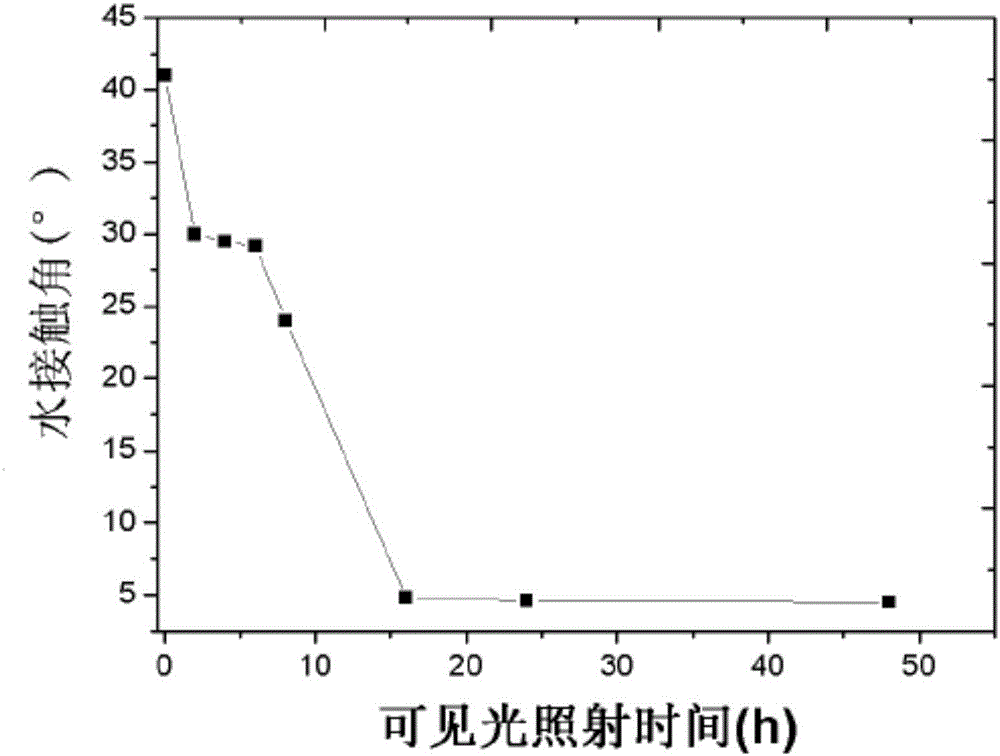

[0057] Example 2: Preparation of silicon-doped nano-TiO with visible light response 2 Self-cleaning ceramic coating.

[0058] Put 540mL of neutral to slightly alkaline deionized water (pH=7.0) into a 1L reaction flask equipped with a stirring device and a heating device, and mix 1mL of tetramethoxysilane, 25mL of titanic acid A mixture of n-butyl ester (TBT) and 80 mL of ethanol (EtOH) was added to the reaction flask to generate a white precipitate. At room temperature and under continuous stirring, 5 mL of 30% hydrogen peroxide (H 2 o 2 ) was added to the suspension until at least 80% of the white precipitate was dissolved, and left to age for 22 hours to obtain a yellow transparent sol. Turn on stirring and heating, heat up to reflux (about 95°C), reflux for 8h, and use 3-4mL concentration of 25% ammonia (NH 3 ·H 2 O) As a pH regulator, adjust the pH of the system to 6.5, and then naturally cool to room temperature to obtain silicon-doped nano-TiO 2 Sol. Then, doping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com