Preparation method of M-phase vanadium dioxide

A technology of vanadium dioxide and vanadium salt, applied in vanadium oxide, nanotechnology for materials and surface science, nanotechnology, etc. Treatment and other problems to achieve the effect of reducing vanadium-containing wastewater, reducing production costs and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

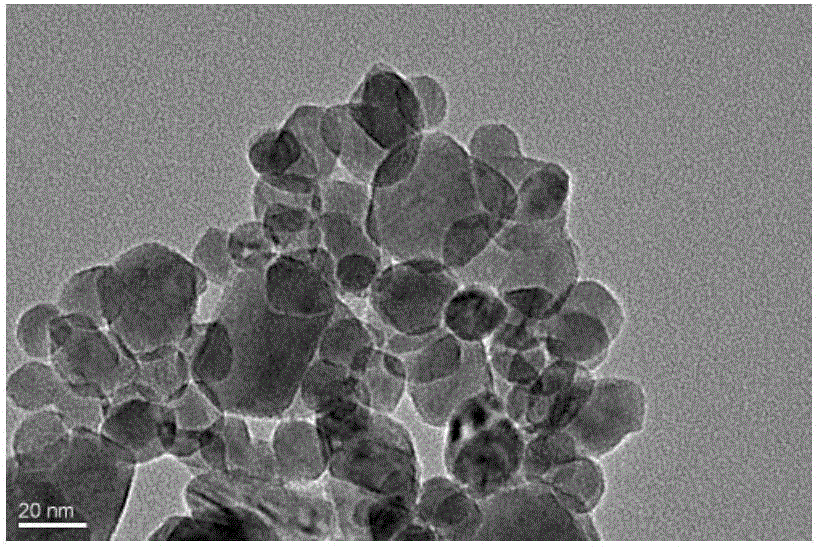

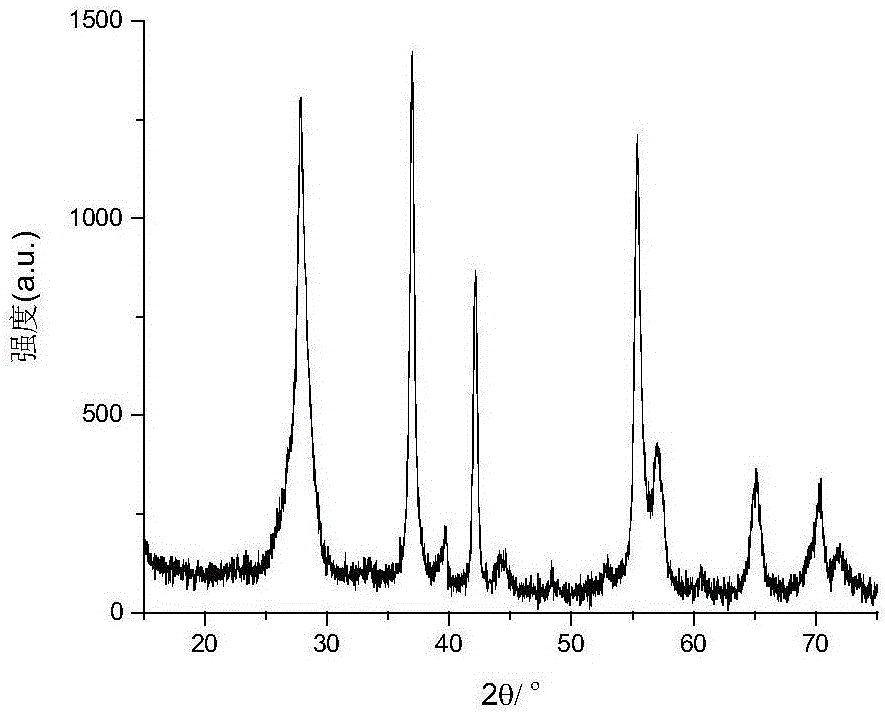

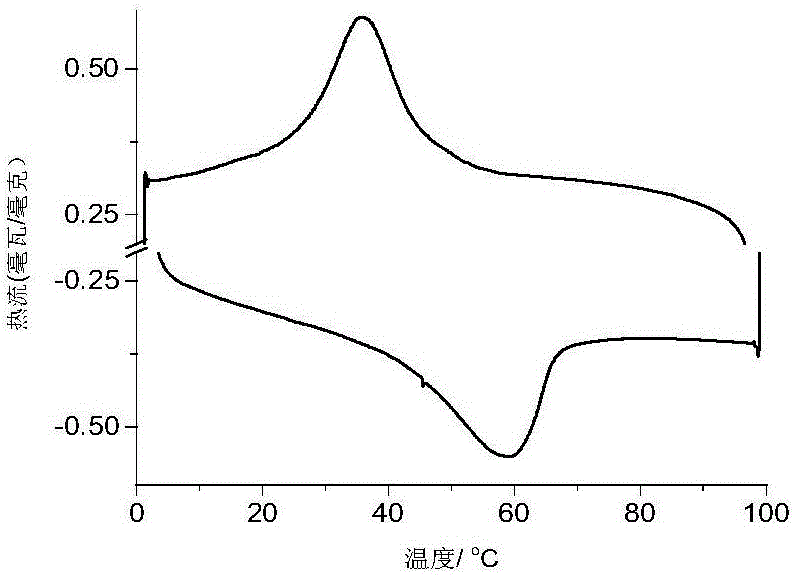

[0030] Weigh 1 g of ammonium metavanadate, add 30 mL of deionized water, heat to 100 ° C to dissolve, and then quickly add a 5% hydrazine solution (the molar ratio of hydrazine to ammonium metavanadate is 1:4), Incubate at 100°C for 10 minutes, heat at 100°C to evaporate the solvent; then add deionized water to form a suspension, and ultrasonically disperse for 10 minutes to obtain a precursor dispersion (in terms of the mass of vanadium dioxide, the mass of the precursor dispersion concentration of 5%). The dispersion was transferred to a 20 mL reactor, hydrothermally treated at 260°C for 24 hours, after the hydrothermal crystallization was completed, the product was obtained by centrifugation, washed three times with water and ethanol, and then washed once with acetone. After drying at ℃, 0.7g M-phase VO can be obtained 2 Nano powder. The obtained powder particle size is as figure 1 As shown, most of the particles have a particle size of about 20 nm, and the largest does ...

Embodiment 2

[0032] Weigh 0.1g of ammonium metavanadate, add 5mL of deionized water, heat to 100°C to dissolve, and then quickly add a 5% diluted hydrazine solution (the molar ratio of hydrazine to ammonium metavanadate is 1:1) Incubate at 100 ° C until the solvent is completely evaporated; then add deionized water to form a suspension, and ultrasonically disperse for 10 minutes to obtain a precursor dispersion (in terms of the mass of vanadium dioxide, the mass concentration of the precursor dispersion is 0.5%). The dispersion was transferred to a 20 mL reaction kettle, and hydrothermally treated at 240 ° C for 48 hours. After the hydrothermal crystallization was completed, the product was obtained by vacuum filtration, washed three times with water and ethanol, and then once with acetone. After drying at 40℃, 0.07gM phase VO can be obtained 2 Nano powder. The powder can be directly added into 10 mL of deionized water to form a vanadium dioxide colloid, and the colloid has good stabilit...

Embodiment 3

[0034] Weigh 2g of ammonium metavanadate, add 30mL of deionized water, heat to 80°C to dissolve, then quickly add L-ascorbic acid (the molar ratio of L-ascorbic acid and ammonium metavanadate is 1:2), keep at 80°C for 10 minutes , heated at 100 ° C to evaporate the solvent; then added deionized water to form a suspension, ultrasonically dispersed for 10 minutes to obtain a precursor dispersion (in terms of the mass of vanadium dioxide, the mass concentration of the precursor dispersion is 5%) . The dispersion was transferred to a 20 mL reaction kettle, and hydrothermally treated at 180 ° C for 240 hours. After the hydrothermal crystallization was completed, the product was obtained by centrifugal separation, washed three times with water and ethanol, and then once with acetone. ℃ drying, you can get 1.4gM phase VO 2 Nano powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com