Desulfurization waste water resourceful treatment system and method

A technology for treating system and desulfurization wastewater, applied in energy wastewater treatment, gaseous effluent wastewater treatment, multi-stage water treatment, etc., can solve the problems of adverse effects of evaporation and crystallization on normal operation, affecting system stability and reuse of produced water, etc. To achieve the effect of ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

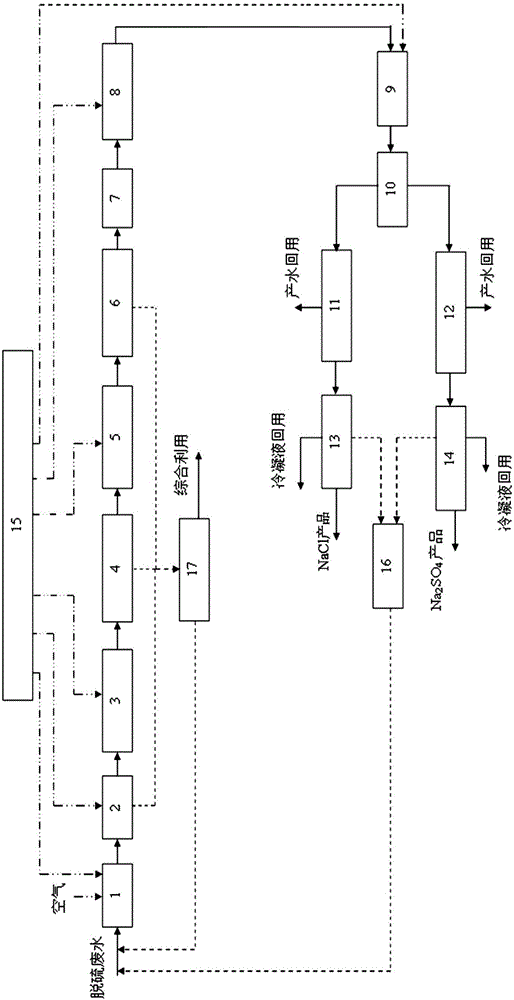

[0049] This embodiment is used to illustrate the desulfurization wastewater resource treatment system and method of the present invention, specifically to treat a kind of desulfurization wastewater generated in the process of SCR denitrification of flue gas and limestone-wet desulfurization in a chemical enterprise's self-provided power plant.

[0050] The main indicators of the wastewater are as follows: pH value 5.0~6.5, conductivity ≤50000μs / cm, chloride ion ≤15000mg / L, ammonia nitrogen ≤400mg / L, COD Cr ≤300mg / L, calcium ≤4000mg / L, magnesium ≤3000mg / L, suspended matter ≤60000mg / L.

[0051] Take the following steps to process:

[0052] 1) Discharge the desulfurization wastewater into the buffer pool 1 and pass it into the air for aeration, stirring, and adding sodium hypochlorite, and the effluent COD Cr content dropped below 50mg / L;

[0053] 2) Transfer the effluent from the buffer tank 1 to the pre-sedimentation tank 2, add coagulant 50 mg / L and coagulant aid 0.5 mg / L th...

Embodiment 2

[0068] This embodiment is used to illustrate the desulfurization wastewater resource treatment system and method of the present invention, specifically to treat a kind of desulfurization wastewater generated in the process of power plant flue gas SCR denitrification and limestone-wet desulfurization.

[0069] The main indicators of the wastewater are as follows:

[0070] pH value is 5.0~6.5, conductivity≤30000μs / cm, chloride ion≤10000mg / L, ammonia nitrogen≤80mg / L, COD Cr ≤200mg / L, calcium ≤1000mg / L, magnesium ≤4000mg / L, suspended matter ≤50000mg / L.

[0071] Take the following steps to process:

[0072] 1) Discharge the desulfurization wastewater into the buffer pool 1 and pass it into the air for aeration, stirring, and adding sodium hypochlorite, and the effluent COD Cr content dropped below 50mg / L;

[0073] 2) Transfer the effluent from the buffer tank 1 to the pre-sedimentation tank 2, add coagulant 50 mg / L and coagulant aid 0.5 mg / L through the dosing system 15, the res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com