Method for improving anaerobic digestion performance of excess activated sludge

A technology of anaerobic digestion and residual activity, applied in chemical instruments and methods, sludge treatment, biological sludge treatment, etc., can solve the problems of incomplete degradation of organic matter, low methane production efficiency, low efficiency, etc., to overcome the degradation of organic matter Incomplete, increased methane yield, avoiding the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection claimed by the present invention is not limited thereto.

[0023] The method for improving the anaerobic digestion performance of excess activated sludge of the present invention comprises the following steps:

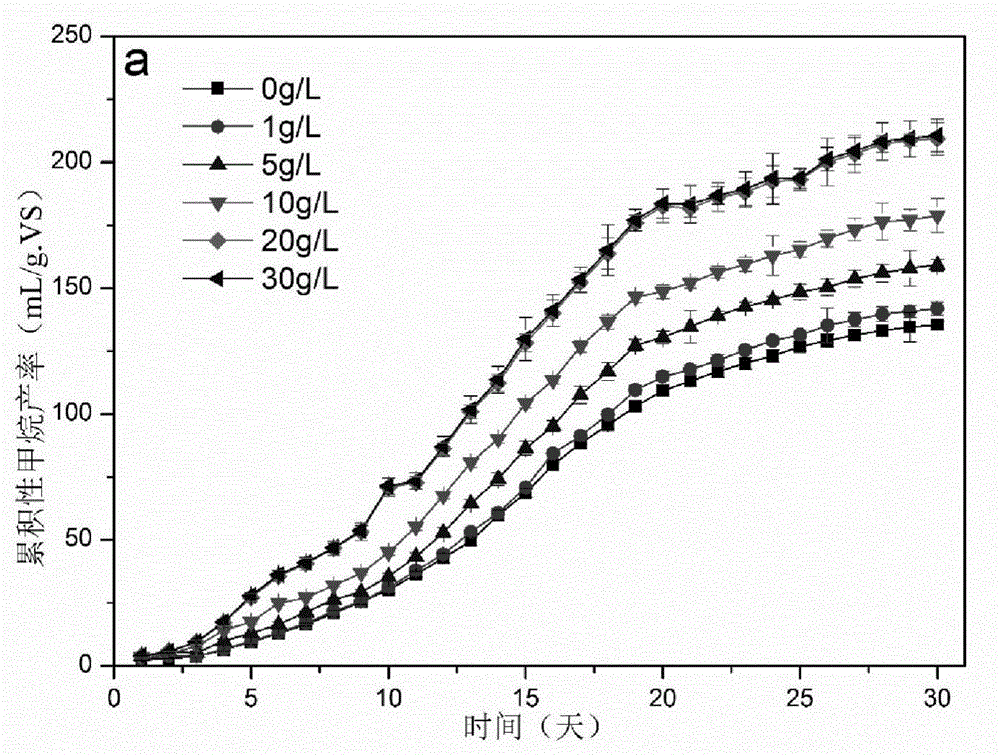

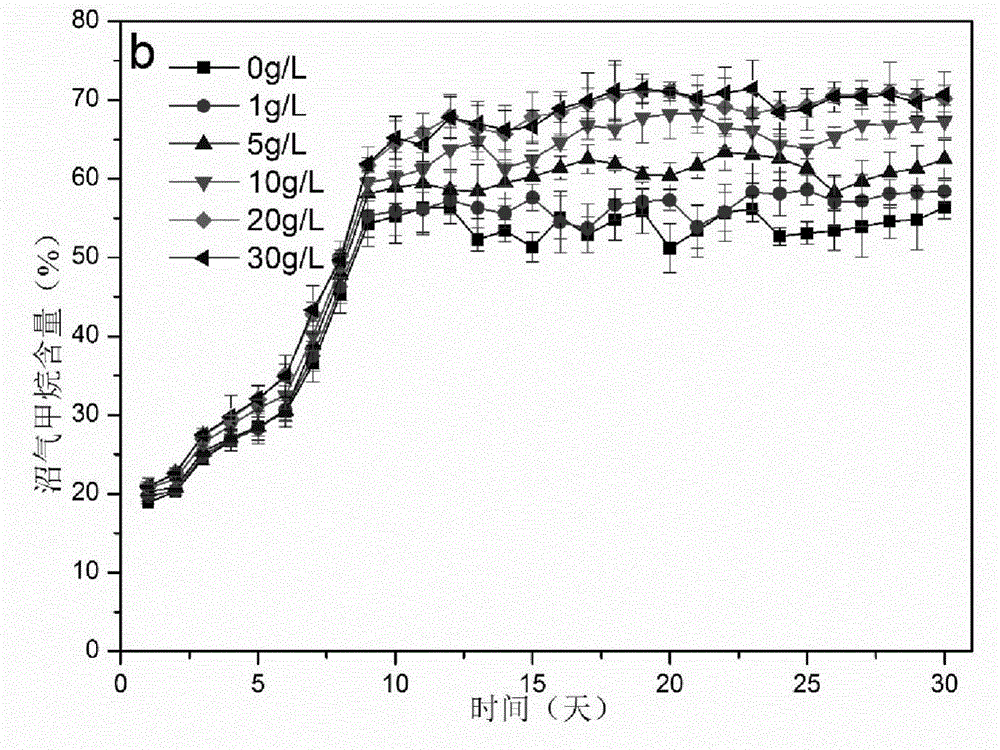

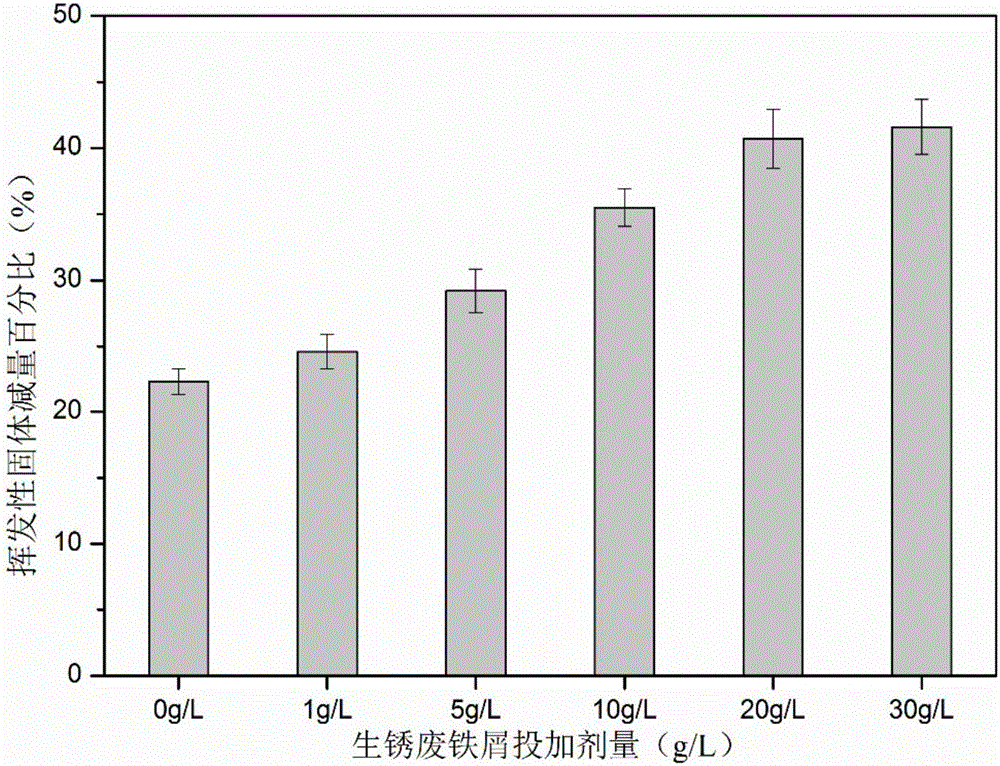

[0024] Step 1, the inoculation seed sludge comes from a fully mixed and stirred reactor in the laboratory of the research group, and the inoculated seed sludge of the completely mixed and stirred reactor is taken from the anaerobic granular sludge bed (EGSB) of the sewage treatment station of Suqian Yanghe Distillery. The remaining activated sludge digested was taken from the secondary settling tank of the sewage treatment plant in Jiangning Economic Development Zone, Nanjing; the volume ratio of the inoculated sludge to the remaining activated sludge was 1:3, and diluted with distilled water to the total soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com