Wet-mixed mortar additive and preparation method thereof

A technology of wet mixing mortar and additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

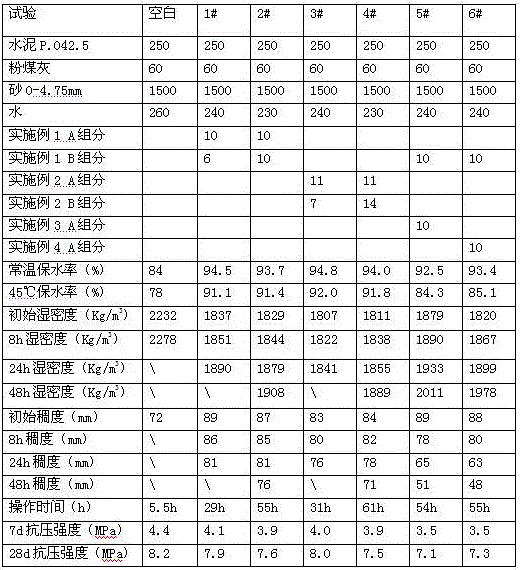

Embodiment 1

[0019] 1. Formulation (weight percentage)

[0020] A component:

[0021] Methyl Hydroxyethyl Cellulose Ether 1.0%

[0022] Sodium α-olefin sulfonate 0.1%

[0023] Sodium Fatty Alcohol Polyoxyethylene Ether Sulfate 0.2%

[0024] Polycarboxylate superplasticizer 2.5%

[0025] Silicone polyether emulsion 0.05%

[0028] Kathon preservative 0.2%

[0029] Water 92.45%

[0030] B component:

[0031] Sodium Gluconate 15%

[0032] Sucrose 5%

[0033] Borax 2%

[0034] Kathon preservative 0.2%

[0035] Water 77.8%

[0036] 2. Preparation

[0037] Preparation of component A: According to the above formula, add 1 / 2 of the water in the mixing tank, heat up to 80°C, put sodium chloride and lithium carbonate in hot water, and stir with a mixer at a speed of 300 rpm for 5 minutes to Completely dissolve, then add methyl hydroxyethyl cellulose ether and continue to stir for 5 minutes, add the remaining 1 / 2 of water whi...

Embodiment 2

[0040] 1. Formulation (weight percentage)

[0041] A component:

[0042] Methyl Hydroxyethyl Cellulose Ether 1.0%

[0043] Sodium Fatty Alcohol Polyoxyethylene Ether Sulfate 0.3%

[0044] Polycarboxylate superplasticizer 2.0%

[0045] Disodium EDTA 0.1%

[0046] Sodium Sulfate 3.5%

[0047] Triethanolamine 1.3%

[0048] Kathon preservative 0.3%

[0049] Water 91.5%

[0050] B component:

[0051] Sodium Gluconate 10%

[0052] Sucrose 15%

[0053] Borax 2.5%

[0054] Kathon preservative 0.4%

[0055] Water 72.1%

[0056] 2. Preparation

[0057] Preparation of component A: According to the above formula, add 1 / 2 of the water in the mixing tank, raise the temperature to 82°C, put sodium sulfate and triethanolamine in hot water, and stir with a mixer at a speed of 300 rpm for 7 minutes until complete Dissolve, then add methyl hydroxyethyl cellulose ether and continue stirring for 5 minutes, while stirring, add the remaining 1 / 2 of water, lower the temperature to norma...

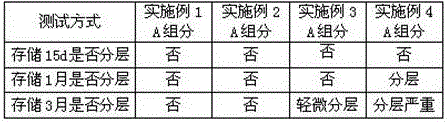

Embodiment 3

[0060] 1. Formulation (weight percentage)

[0061] Component A: methyl hydroxypropyl cellulose ether 1.0%

[0062] Sodium Fatty Alcohol Polyoxyethylene Ether Sulfate 0.3%

[0063] Polycarboxylate superplasticizer 2.0%

[0064] Disodium EDTA 0.1%

[0065] Sodium Sulfate 3.5%

[0066] Triethanolamine 1.3%

[0067] Kathon preservative 0.3%

[0068] Water 91.5%

[0069] B component: formula is identical with the B component of embodiment 1.

[0070] 2. Preparation

[0071] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com