Method for activating water supply plant sludge-base haydite to enhance phosphorus adsorption effect

A technology for water supply plant sludge and water supply sludge, which is applied in the field of water treatment, can solve the problems of restricting the wide use of water supply plant sludge, low sludge doping amount, poor adsorption effect, etc. The effect of mud content and protection of cultivated land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The method for preparing ceramsite with waterworks sludge, the specific steps are as follows:

[0031] (1) Naturally dry the sludge from the water supply plant, crush it, and sieve it to make the particle size ≤ 125 μm;

[0032] (2) After mixing the sludge and clay from the water supply plant with a mass of 2:1, put them in the ball forming machine, set the speed of the ball machine to 40rpm, spray water with a mass of about 15% of the material mass, and granulate into balls;

[0033] (3) Sieve to obtain raw material balls with a particle size of 0.8mm ~ 1mm, dry them naturally, move them into a muffle furnace and preheat them at 400°C for 20 minutes, then raise the temperature to 900°C, roast them for 10 minutes, and cool down in the furnace to obtain the raw meal balls. Clay ceramsite.

[0034] The cylinder compressive strength of the ceramsite is 4.3MPa, and the specific surface area is 2.7m 2 / g.

Embodiment 2

[0036] The activation method for preparing ceramsite from waterworks sludge, the specific steps are as follows:

[0037] (1) Weigh 3 parts of 5g ceramsite, place them in 50mL HCl solution with a concentration of 0.5mol / L, 1mol / L, and 2mol / L respectively, and soak for 24h;

[0038] (2) Filter out the ceramsite, wash it with deionized water, and dry to obtain the activated water plant sludge ceramsite.

Embodiment 3

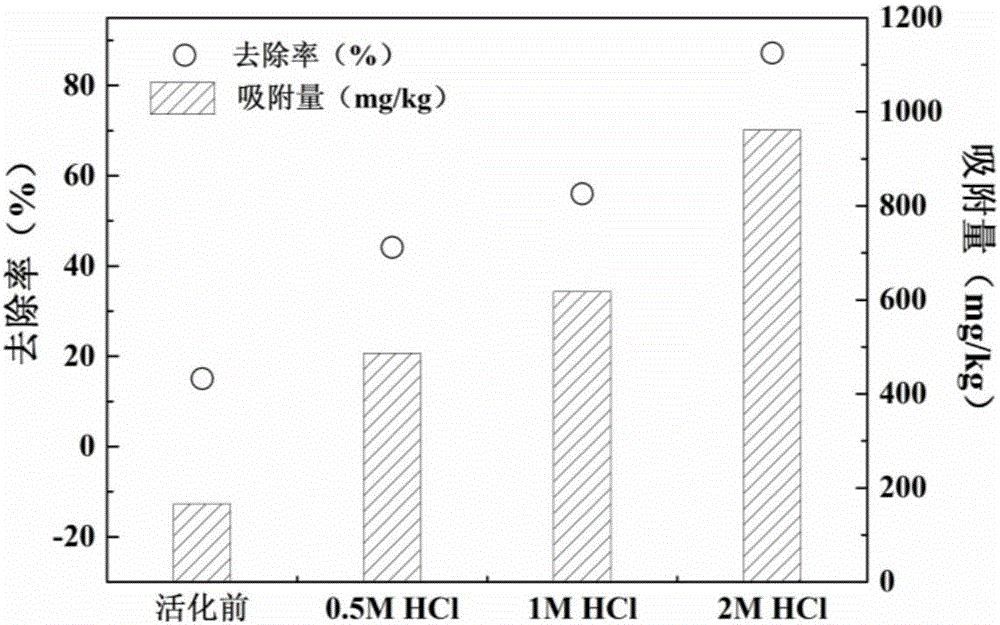

[0040] Determination of Phosphorus Adsorption Performance of Feedwater Sludge Ceramsite Before and After Activation

[0041] Prepare KH with an initial concentration of 50mg / L 2 PO 4 The solution simulates phosphorus-containing wastewater, adding the feedwater sludge ceramsite before and after activation prepared in Example 1-2, under the condition that the solid-to-liquid ratio is 1:100, vibrate at a speed of 100 rpm in a shaking incubator for 100 h, before and after activation The phosphorus removal effect of ceramsite is as figure 2 shown. It can be seen from the figure that the phosphorus removal effect of ceramsite after activation is significantly improved, and with the increase of hydrochloric acid concentration, the removal rate and adsorption capacity gradually increase. When the concentration of hydrochloric acid is 2mol / L, the removal rate of ceramsite to phosphorus in the solution is as high as 87%, and the adsorption capacity is 961mg / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Cylinder compressive strength | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com