Preparation method of phosphate-reinforced zirconia fiber high-efficiency thermal-insulation composite material

A technology of zirconia fiber and composite materials, which is applied in the field of preparation of inorganic composite materials, can solve the problems of poor mechanical properties of heat insulation materials, poor mechanical properties of heat insulation tiles, and low strength of inorganic binders, and achieve easy implementation and production The effect of short cycle time and good high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

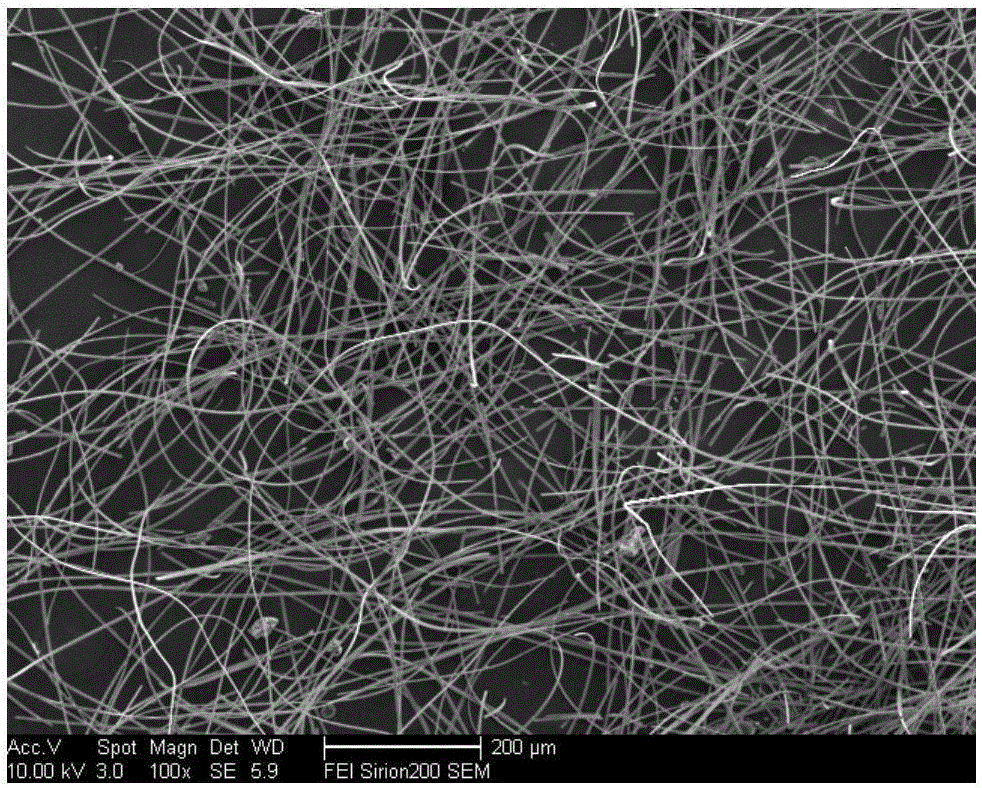

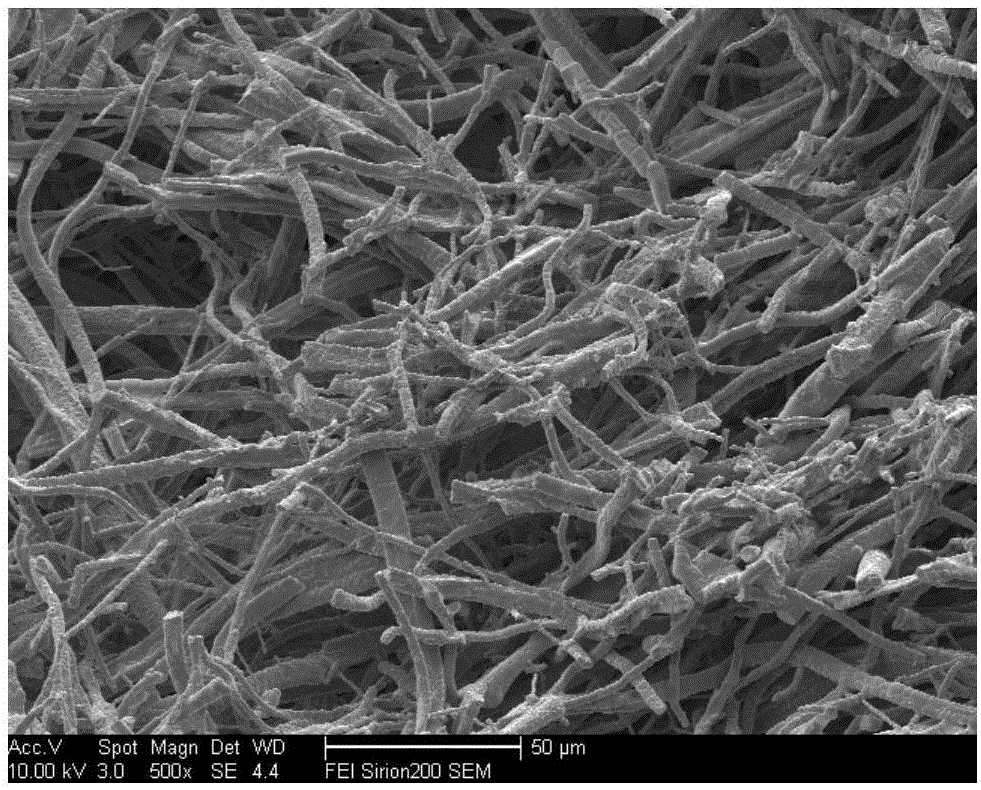

[0032] Weigh 2000gLaCl 3 ·6H 2 O, add to 10000g deionized water, stir until the powder is completely dissolved, add 1000gH 3 PO 4 , Stir with a micro stirrer for 30 minutes, and let it stand for 12 hours after the solution is evenly mixed. Mix the chopped zirconia fiber (average length 30μm), the binder lanthanum phosphate solution with 200% of the zirconia fiber mass, and the deionized water with 3000% of the zirconia fiber mass, and stir for 40 minutes with a micro stirrer to make the fiber Slurry. The vacuum degree of the vacuum tank is maintained at -0.1MPa, the slurry is added to the mold for collection, the vacuum filtration treatment time is 10 minutes, and the vacuum filtration is formed into a wet green. The wet billet is placed in a constant temperature drying box, and the drying process is 70°C for 12 hours and 140°C for 4 hours. After drying, the wet billet is placed in a high-temperature sintering furnace and fired at 1500°C under normal pressure. The temperature ...

Embodiment 2

[0034] Weigh 2000gLaCl 3 ·6H 2 O, add to 10000g deionized water, stir until the powder is completely dissolved, add 1000gH 3 PO 4 , Stir with a micro stirrer for 30 minutes, and let it stand for 12 hours after the solution is evenly mixed. Mix the chopped zirconia fiber (average length 150μm), the binder lanthanum phosphate solution with 500% of the zirconia fiber mass, and the deionized water with 2500% of the zirconia fiber mass, and stir for 40 minutes with a micro stirrer to make the fiber Slurry. The vacuum degree of the vacuum tank is kept at -0.06MPa, the slurry is added to the mold for collection, the vacuum filtration treatment time is 10 minutes, and the vacuum filtration is formed into a wet green. The wet billet is placed in a constant temperature drying box, and the drying process is 50°C for 24 hours and 140°C for 4 hours. After drying, the wet billet is placed in a high-temperature sintering furnace and fired at 1500°C under normal pressure. The temperature is k...

Embodiment 3

[0036] Weigh 2500gLaCl 3 ·6H 2 O, add to 10000g deionized water, stir until the powder is completely dissolved, add 1000gH 3 PO 4 , Stir with a micro stirrer for 30 minutes, and let it stand for 12 hours after the solution is evenly mixed. Mix the chopped zirconia fiber (average length 30μm), the binder lanthanum phosphate solution with 100% zirconia fiber mass, and 3000% deionized water with zirconia fiber mass, and stir for 40 minutes with a micro stirrer to make fiber Slurry. The vacuum degree of the vacuum tank is kept at -0.05MPa, the slurry is added to the mold for collection, the vacuum filtration treatment time is 10 minutes, and the vacuum filtration is formed into a wet green. The wet billet is placed in a constant temperature drying box, and the drying process is 70°C for 12 hours and 140°C for 4 hours. After drying, the wet billet is placed in a high-temperature sintering furnace and fired at 1550°C under normal pressure, and kept for 5 hours to cool to room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com