Process for cooperative production of functional biological organic fertilizer from molasses alcohol concentrated liquid

A bio-organic fertilizer and molasses alcohol technology, which is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, organic fertilizers, etc., can solve the problems of limited quality improvement, inability of microorganisms to fully ferment and decompose harmful substances, and small additions to achieve finished products Good growth promotion, thorough harmless treatment, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

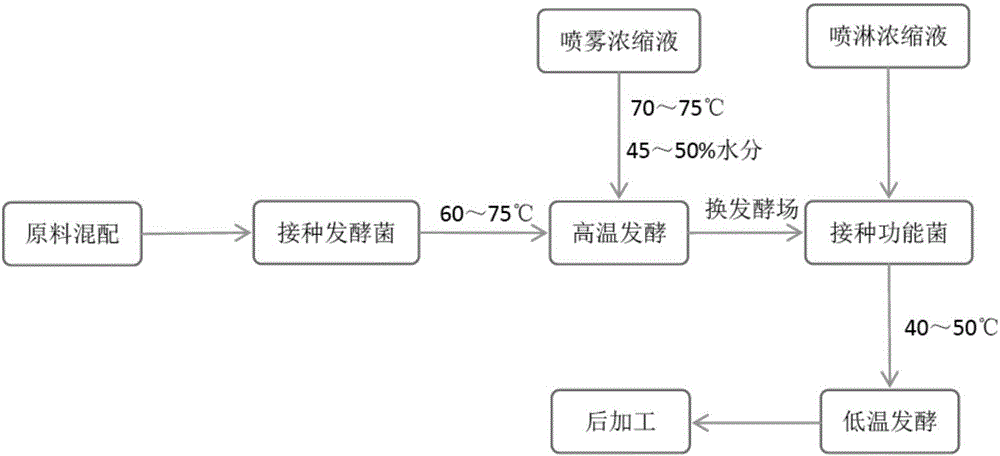

[0055] The bio-organic fertilizer production process adopts the tank-type aerobic fermentation process, which is divided into two stages of high-temperature fermentation (60-75°C) and low-temperature fermentation (40-50°C). The process requirements are also different for the method of adding the concentrate. Process flow chart such as figure 1 shown.

[0056] The first step is to mix the raw materials. The raw material is organic waste, the composition of the organic waste and the mass percentage of each component are 30% of filter mud, 10% of tobacco dust, 10% of cassava alcohol residue, 10% of sugarcane pith, 5% of soybean bran, and barrel bran 5%, peanut bran 2%, potassium ash 2%. The proportions of the above substances are set and adjusted according to the C / N ratio, initial moisture, initial organic matter, porosity, nutrients, etc. Use a forklift to shovel into the feed port of each fermentation tank layer by layer (no mixer premixing is required, so as not to reduce ...

Embodiment 2

[0066] The bio-organic fertilizer production process adopts the tank-type aerobic fermentation process, which is divided into two stages of high-temperature fermentation (60-75°C) and low-temperature fermentation (40-50°C). The process requirements are also different for the method of adding the concentrate. Process flow chart such as figure 1 shown.

[0067] The first step is to mix the raw materials. The raw material is organic waste, the composition of the organic waste and the mass percentage of each component are filter mud 40%, tobacco dust 15%, cassava alcohol residue 15%, sugarcane pith 15%, soybean bran 10%, barrel bran 10%, peanut bran 5%, potassium ash 5%. The proportions of the above substances are set and adjusted according to the C / N ratio, initial moisture, initial organic matter, porosity, nutrients, etc. Use a forklift to shovel into the feed port of each fermentation tank layer by layer (no mixer premixing is required, so as not to reduce the porosity), fo...

Embodiment 3

[0077] The bio-organic fertilizer production process adopts the tank-type aerobic fermentation process, which is divided into two stages of high-temperature fermentation (60-75°C) and low-temperature fermentation (40-50°C). The process requirements are also different for the method of adding the concentrate. Process flow chart such as figure 1 shown.

[0078] The first step is to mix the raw materials. The raw material is organic waste, the composition of the organic waste and the mass percentage of each component are filter mud 35%, tobacco dust 12.5%, cassava alcohol residue 12.5%, sugarcane pith 12.5%, soybean bran 7.5%, barrel bran 7.5%, peanut bran 2.5%, potassium ash 2.5%. The proportions of the above substances are set and adjusted according to the C / N ratio, initial moisture, initial organic matter, porosity, nutrients, etc. Use a forklift to shovel into the feed port of each fermentation tank layer by layer (no mixer premixing is required, so as not to reduce the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com