A kind of fertilizer containing natural plant growth substance and its preparation process

A natural plant and preparation technology, applied to fertilizers made of biological waste, organic fertilizers, ammonium salt fertilizers, etc., can solve the problems of insufficient extraction of plant hormones, complicated microbial screening process, and low rate of cell wall breaking during operation. Achieve the effects of improving crop quality and yield, promoting synthesis, and enhancing photosynthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

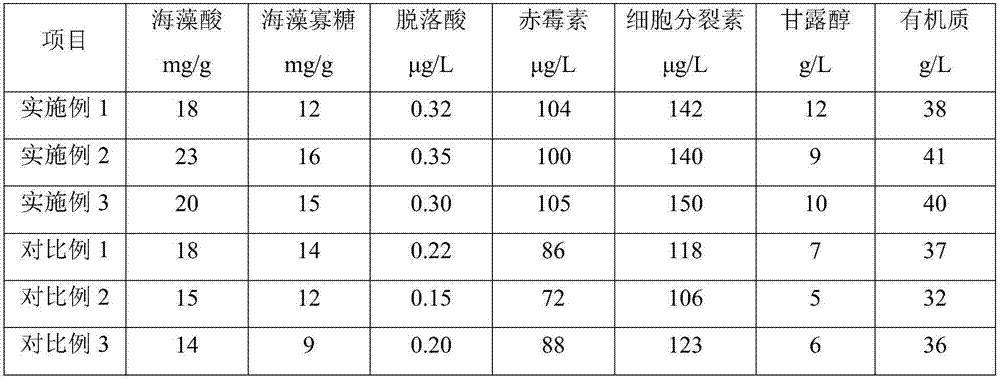

[0038] Embodiment 1 contains the fertilizer of natural plant growth substance and its preparation

[0039] Embodiment 1 of the present invention contains the fertilizer of natural plant growth substance, and its preparation process comprises the steps:

[0040] S1: Clean the kelp, dry it in the sun, crush it, add 0.5‰ sodium hexametaphosphate and 3‰ Sapindus saponin, mix well and add water at a temperature of 25 Extract under the condition of ℃ for 90min, filter to obtain the extract I; add water to the filtered kelp according to the ratio of material to liquid 1:3g / mL and add water for 60min under the condition of 25℃, filter to obtain the extract II, keep The kelp residue is set aside; the extract I and the extract II are combined, mixed and then concentrated under reduced pressure to 1 / 3 of the original volume to obtain a concentrated extract;

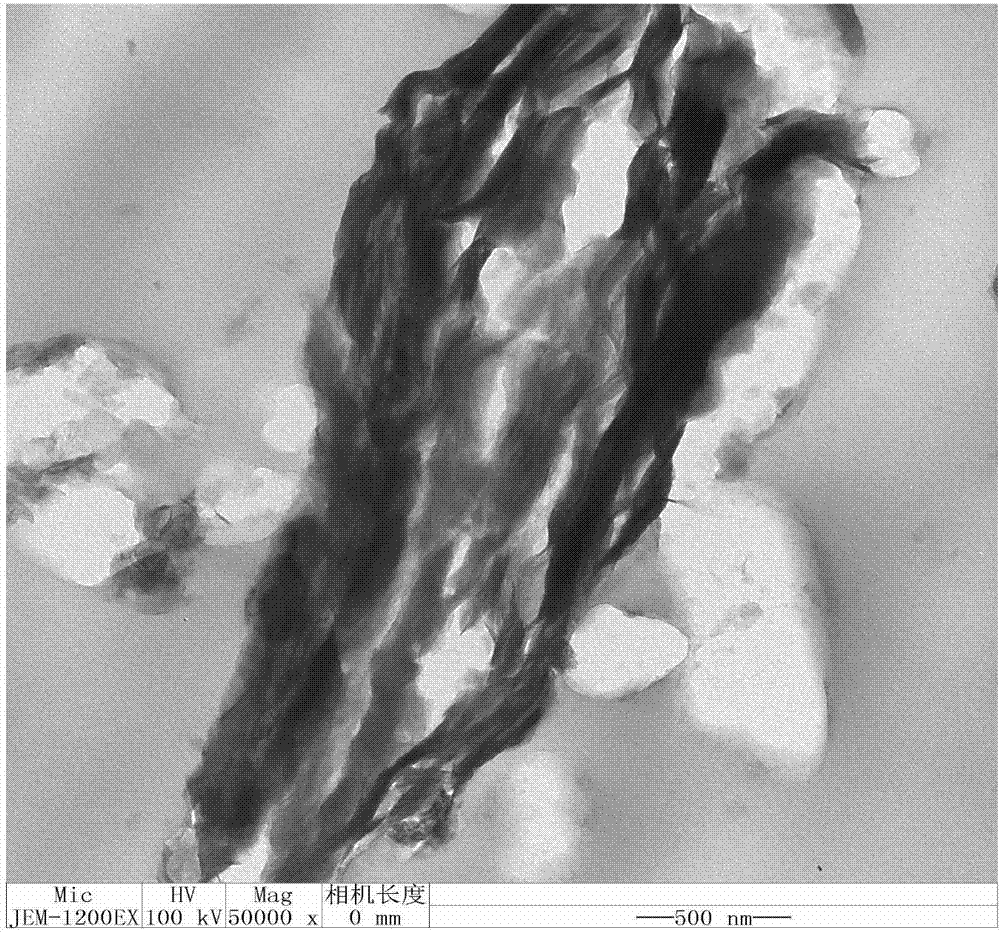

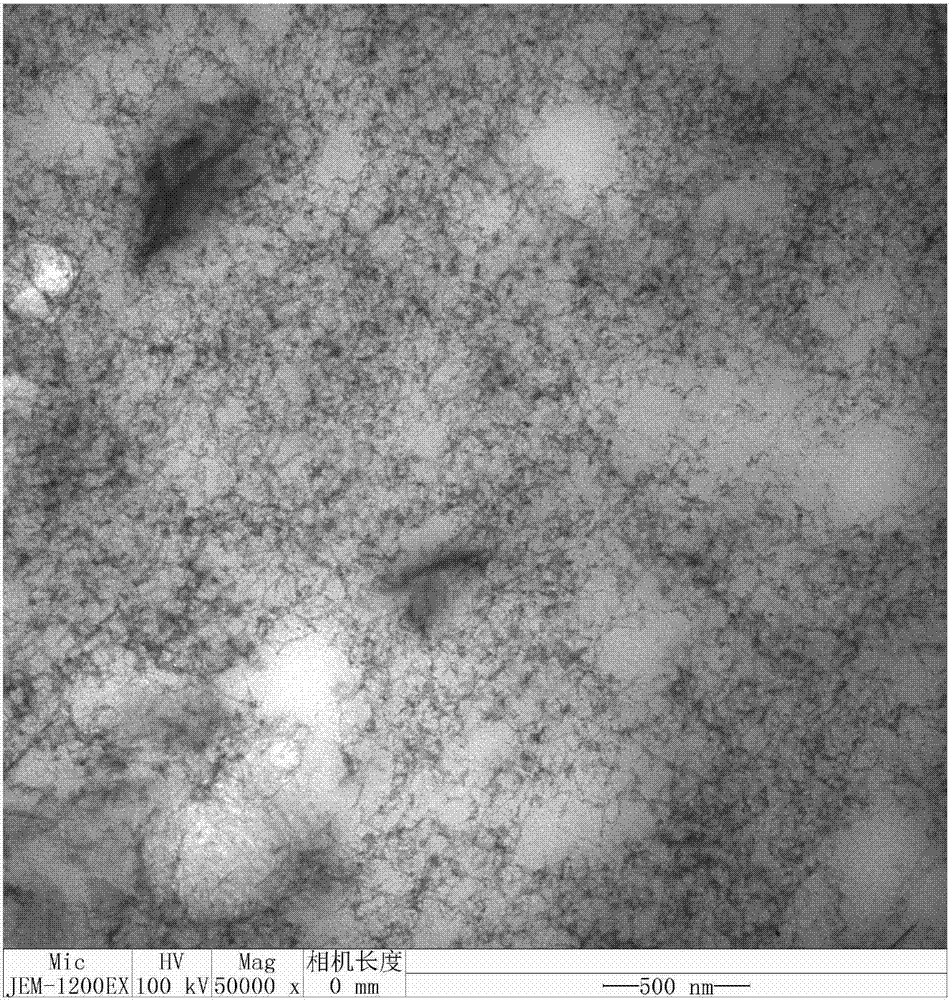

[0041] S2: Mix the kelp slag with water according to the material-to-liquid ratio of 1:8g / mL, add cellulase with a mass of 1.2% k...

Embodiment 2

[0043] Embodiment 2 contains the fertilizer of natural plant growth substance and its preparation

[0044] Embodiment 2 of the present invention contains the fertilizer of natural plant growth substance, and its preparation process comprises the steps:

[0045] S1: Remove impurities from the kelp, wash it, dry it in the sun, crush it, add 2‰ sodium hexametaphosphate and 8‰ sapinberry saponin, mix well, add water at a temperature of 35 Extract under the condition of ℃ for 60min, and filter to obtain the extract I; add water to the filtered kelp according to the ratio of 1:2g / mL to extract for 30min at a temperature of 35℃, filter to obtain the extract II, keep The kelp residue is set aside; the extract I and the extract II are combined, mixed and then concentrated under reduced pressure to 1 / 5 of the original volume to obtain a concentrated extract;

[0046] S2: Mix kelp slag with water according to the material-to-liquid ratio of 1:12g / mL, add cellulase with a mass of 1.8% ke...

Embodiment 3

[0048] Embodiment 3 contains the fertilizer of natural plant growth substance and its preparation

[0049] Embodiment 3 of the present invention contains the fertilizer of natural plant growth substance, and its preparation process comprises the steps:

[0050] S1: Remove impurities from the kelp, wash it, dry it in the sun, crush it, add 1‰ sodium hexametaphosphate and 5‰ Sapindus saponin, mix well and add water according to the ratio of material to liquid: 1:4g / mL Leach at 30°C for 80 minutes, filter to obtain extract I; add water to the filtered kelp at a ratio of 1:3 g / mL and add water to extract for 40 minutes at 30°C, and filter to obtain extract II. Keep the kelp slag for later use; combine the extract I and the extract II, mix well, concentrate under reduced pressure to 1 / 3 of the original volume, and obtain the extract concentrate;

[0051] S2: Mix kelp slag with water according to the material-to-liquid ratio of 1:10g / mL, add cellulase with 1.5% kelp slag mass, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com