A kind of preparation method of highly oriented cellulose film

A technology of cellulose film and high orientation, which is applied in the direction of flat products, bulk chemical production, and other household appliances. It can solve the problems of inaccurate control of orientation degree, poor toughness of cellulose film, complicated preparation process, etc., and achieve easy operation , controllable degree of orientation, simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

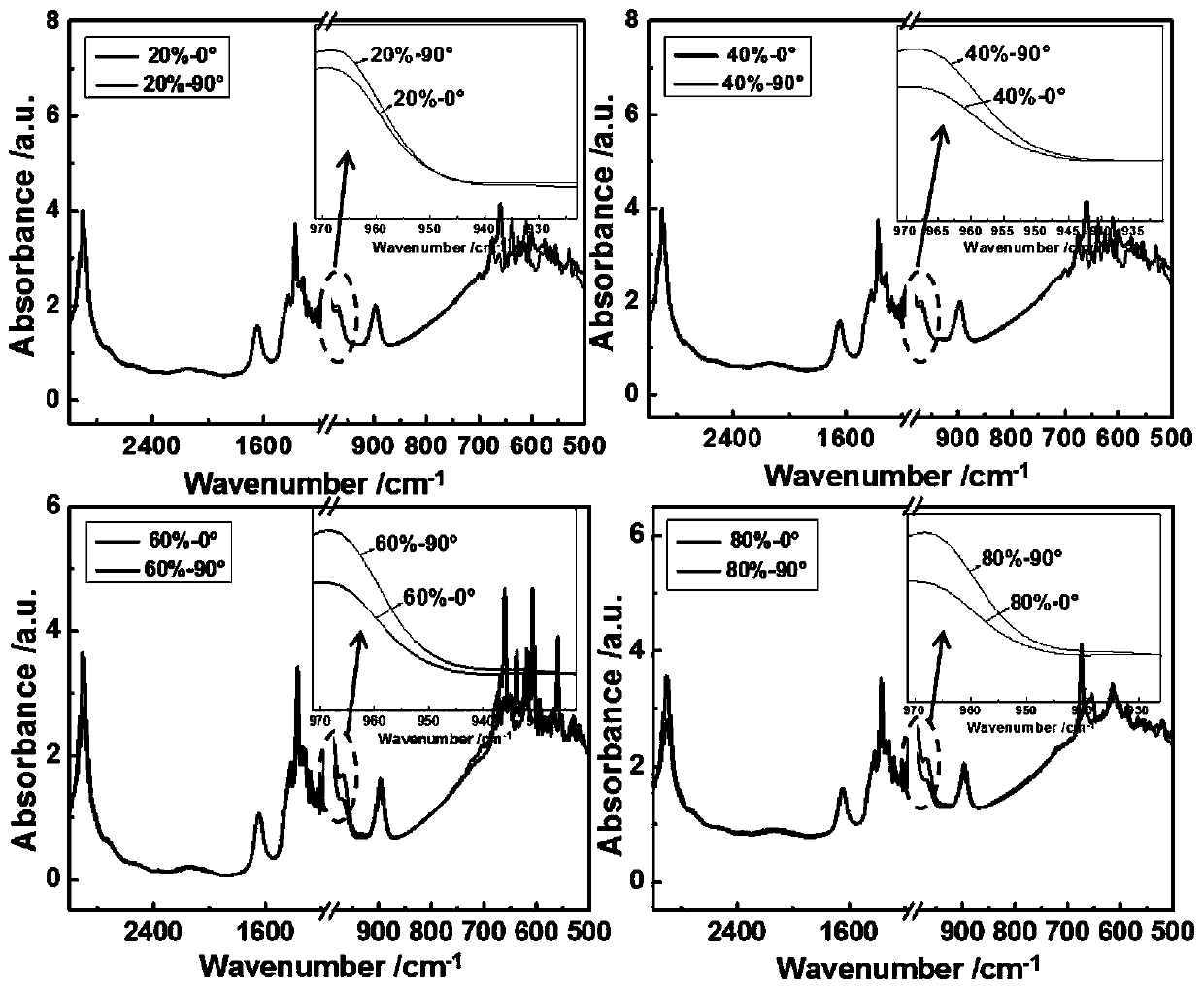

Image

Examples

Embodiment 1

[0049] a. Preparation of cellulose hydrogel film: Prepare 100g of sodium hydroxide / urea / water solution according to the mass ratio of 6.5:11.5:82, place it in -15°C environment for pre-cooling for 3 hours, and then put 3g of cellulose into In the prepared solution, stir at high speed for 5 minutes to obtain a transparent cellulose solution, and then the product is centrifuged by a centrifuge to remove insoluble matter and air bubbles to obtain a cellulose solution with a mass fraction of 3%; the cellulose solution is coated on Keep the glass plate at 20°C for 3 hours, then immerse it in a coagulation bath for regeneration, and wash it with deionized water for 3-4 times to obtain a cellulose hydrogel film;

[0050]B. Plasticization of cellulose hydrogel film: immerse cellulose hydrogel film in plasticizing bath to carry out plasticization, and described plasticizing bath is made up of ionic liquid and deionized water, and mass ratio is 3:97, in Soak at 60°C for 16 hours, then p...

Embodiment 2

[0053] The types of materials used and the process flow are the same as in Example 1, except that the ionic liquid is used as the solvent, and 5 g of cellulose is added to the ionic liquid (the cation is an alkylimidazolium ion, and the anion is a chloride ion) and stirred and dissolved at 90 ° C to obtain a mass fraction of 5% cellulose solution was coated on a glass plate to form a film, and then a cellulose film with a draw ratio of 1.2 was prepared. The degree of orientation of the obtained oriented film was 1.11, the tensile strength was 111 MPa, and the modulus was 7.5 GPa.

Embodiment 3

[0055] The types of materials used and the process flow are the same as in Example 1, except that the mass ratio of ionic liquid and deionized water in the plasticizing bath is 7:93, and the film is taken out after soaking at room temperature for 18h, and then placed in Fix and dry on a plexiglass plate to obtain a plasticized cellulose film. Subsequently, the same method was used to prepare a cellulose film with a stretch ratio of 1.4, a degree of orientation of 1.32, a tensile strength of 127 MPa, and a modulus of 8.7 GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com