Full-biodegradable preservative film and preparation method thereof

A technology of biodegradable polyester and plastic wrap, applied in the field of fully biodegradable plastic wrap and its preparation, can solve the problems of shortening the preservation time of fruits and vegetables, perishable food, and non-compliance of gas barrier and water vapor permeability of plastic wrap , to achieve the effect of improving fresh-keeping storage time and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

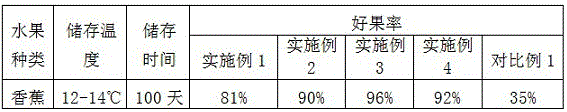

Examples

Embodiment 1

[0021] (1) Dry polylactic acid (produced by NatureWorks, USA, 4032D) and biodegradable polyester PBAT (produced by BASF, blown film grade) in an oven at 60°C for 24 hours, and dry ultrafine talc powder as an inorganic filler in an oven at 100°C 4h.

[0022] (2) Weigh the following components by weight according to the above ratio: 95 parts of polylactic acid, 5 parts of biodegradable polyester PBAT, toughening agent (produced according to the method in Example 1 of the invention patent ZL201410662335.X) 10 0.1 part of ethylene decomposition absorbent potassium permanganate, 5 parts of inorganic filler superfine talc powder, 0.1 part of processing aid lubricant erucamide; add the above raw materials into the high-speed mixer, and mix at room temperature for 5-10 minutes .

[0023] (3) Add the homogeneously mixed raw materials in step (2) into a twin-screw extruder, melt and blend at 120-190° C., extrude, modify and granulate to obtain a special modified material for plastic wr...

Embodiment 2

[0027] (1) Dry polylactic acid (produced by Zhejiang Hisun Company, film grade) and biodegradable polyester PBS (produced by Anqing Hexing Company, blown film grade) in an oven at 80°C for 2 hours, and dry the inorganic filler ultrafine calcium carbonate at 120 ℃ oven dry for 2h.

[0028] (2) Weigh the following components by weight according to the above ratio: 70 parts of polylactic acid, 30 parts of biodegradable polyester PBS, toughening agent (produced according to the method in Example 1 of the invention patent ZL201410662335.X) 6 4 parts of ethylene decomposition absorbent silver oxide, 10 parts of inorganic filler superfine calcium carbonate, 0.3 part of processing aid lubricant calcium stearate, and 0.3 part of antioxidant 1010; Mix at high speed for 5-10 minutes.

[0029] (3) Add the homogeneously mixed raw materials in step (2) into a twin-screw extruder, melt and blend at 120-190° C., extrude, modify and granulate to obtain a special modified material for plastic ...

Embodiment 3

[0033] (1) Dry polylactic acid (produced by Shenzhen Guanghua Weiye Company, film grade) and biodegradable polyester PBSA (produced by Anqing Hexing Company, blown film grade) in an oven at 70°C for 3 hours, and dry ultrafine kaolin with inorganic filler at 110°C Dry in oven for 3h.

[0034] (2) Weigh the following components by weight according to the above ratio: 5 parts of polylactic acid, 95 parts of biodegradable polyester PBSA, toughening agent (produced according to the method in Example 1 of the invention patent ZL201410662335.X) 1 6 parts, ethylene decomposition absorber rare earth oxide 6 parts, inorganic filler superfine kaolin 20 parts, processing aid lubricant calcium stearate 0.5 part, antioxidant 10100.3 parts; Add the above-mentioned raw materials in the high mixer, under normal temperature Mix at high speed for 5-10min.

[0035] (3) Add the homogeneously mixed raw materials in step (2) into a twin-screw extruder, melt and blend at 120-190° C., extrude, modify...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com