A kind of reinforced and toughened self-curing rigid polyimide foam and preparation method thereof

A polyimide, strengthening and toughening technology, applied in the field of strengthening and toughening self-curing rigid polyimide foam and its preparation, can solve the problems of increased energy consumption and limited use, and achieve low moisture absorption rate, Energy consumption, environmental protection, non-toxicity, and the effect of enhancing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

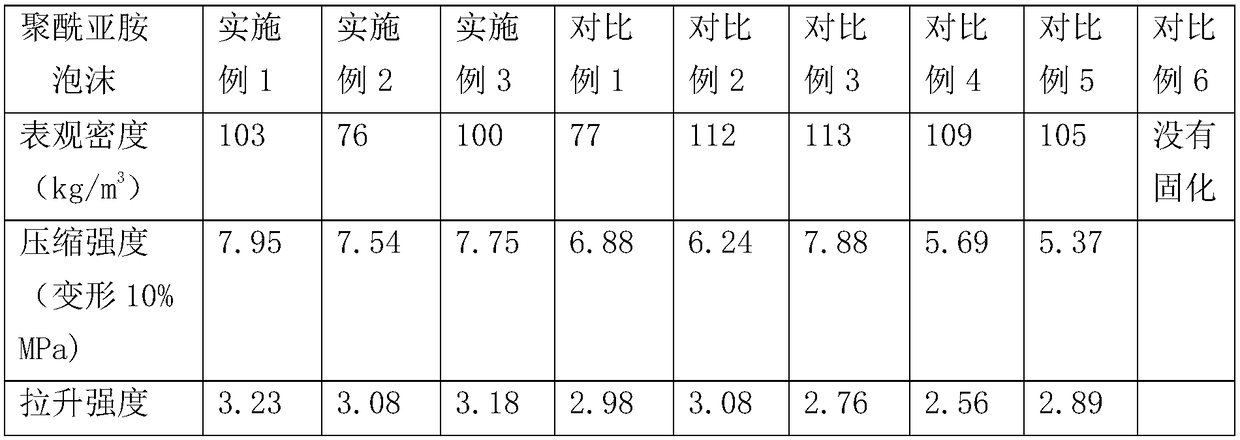

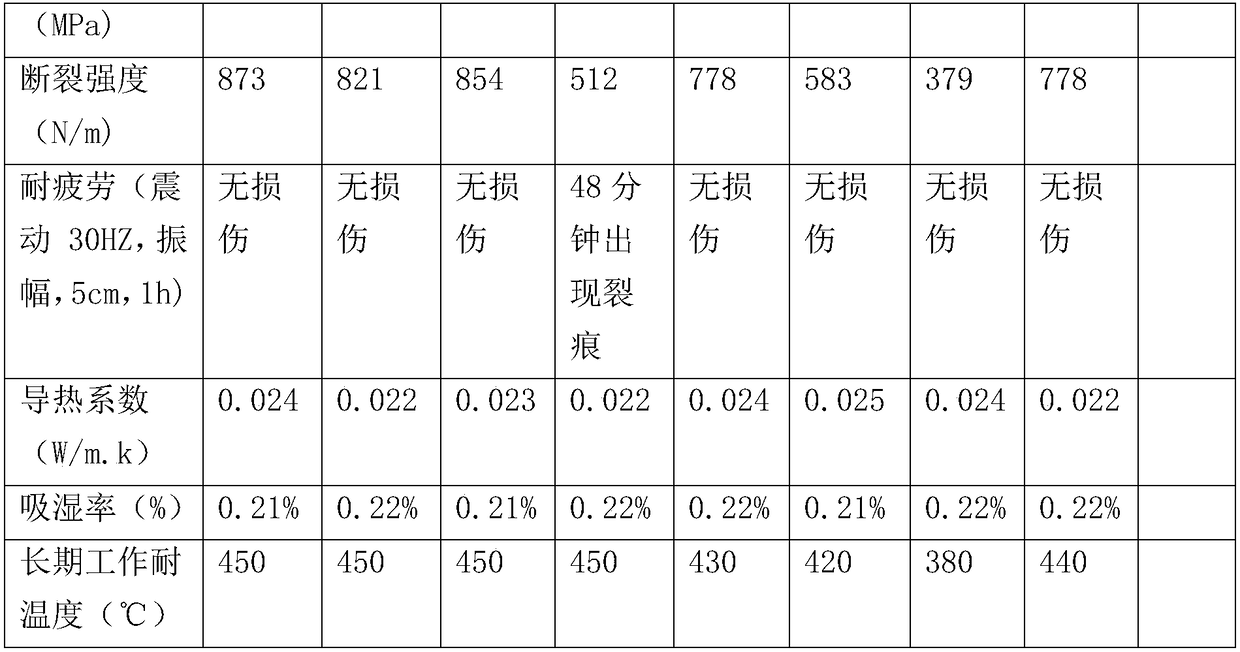

Examples

Embodiment 1

[0034] First, hollow glass microspheres and short glass fibers are subjected to surface modification treatment with coupling agent KH550, the mass ratio of KH550 to glass microspheres / glass fibers is 1:100, and the surface modification treatment is specifically: The above-mentioned glass microspheres / glass fibers are soaked in KH550 aqueous solution with a concentration of 1% by mass for 1 hour, dried at 100° C., and ready for use.

[0035]a. Add a certain amount of aromatic dianhydride into a reaction kettle with furfuryl alcohol as a solvent, then add fatty alcohol for esterification reaction to a clear and transparent solution, control the reaction temperature at 45°C, and react for 2 hours; after the esterification reaction is completed, add Catalyst A, surfactant, stir evenly. Add a certain amount of modified hollow glass microspheres and modified short glass fibers, and use ultrasonic dispersion technology to uniformly disperse them in it to synthesize a foam precursor s...

Embodiment 2

[0042] First, hollow glass microspheres and short glass fibers are subjected to surface modification by coupling agent KH550, the mass ratio of KH550 to glass microspheres / glass fibers is 1:100, and the surface modification process is specifically: The glass microspheres / glass fibers are soaked in 1% KH550 aqueous solution for 1 hour, dried at 100°C, and ready for use.

[0043] a. Add a certain amount of aromatic dianhydride into a reaction kettle with furfuryl alcohol as a solvent, then add fatty alcohol for esterification reaction to a clear and transparent solution, control the reaction temperature at 40°C, and react for 3 hours; after the esterification reaction is completed, add Catalyst A, surfactant, stir evenly. Add a certain amount of modified glass microspheres and modified glass fibers, and use ultrasonic dispersion technology to uniformly disperse them in it to synthesize a foam precursor solution;

[0044] b. Add a certain amount of acid anhydride and catalyst B ...

Embodiment 3

[0049] First, hollow glass microspheres and short glass fibers are subjected to surface modification by coupling agent KH570, the mass ratio of KH570 to glass microspheres / glass fibers is 1:100, and the surface modification process is specifically: The glass microspheres / glass fibers are soaked in 1% KH570 aqueous solution for 1 hour, dried at 100°C, and ready for use.

[0050] a. Add a certain amount of aromatic dianhydride into a reaction kettle with furfuryl alcohol as a solvent, then add fatty alcohol for esterification reaction to a clear and transparent solution, control the reaction temperature at 45°C, and react for 2 hours; after the esterification reaction is completed, add Catalyst A, surfactant, stir evenly. Add a certain amount of modified glass microspheres and modified glass fibers, and use ultrasonic dispersion technology to uniformly disperse them in it to synthesize a foam precursor solution;

[0051] b. Add a certain amount of acid anhydride and catalyst B ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com